Prefabricating concrete column and column fabricating type connecting joint

A technology of precast concrete and connecting nodes, which is applied to buildings and building structures, etc., can solve the problems of easy occurrence of voids, slow construction speed, slurry leakage and voids, etc., to achieve convenient connection quality, fast construction and installation, and finished products. Quality controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

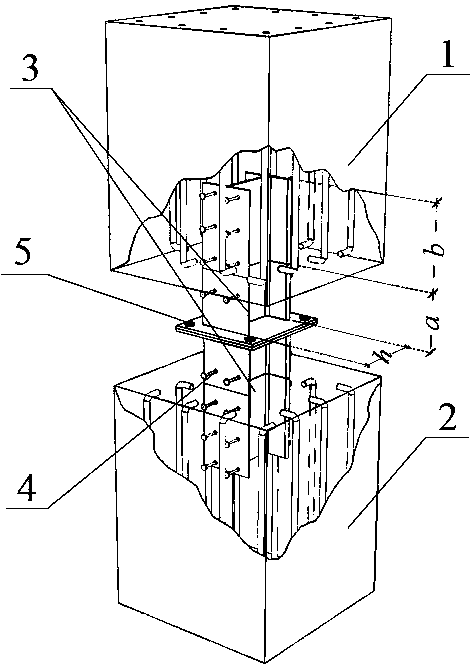

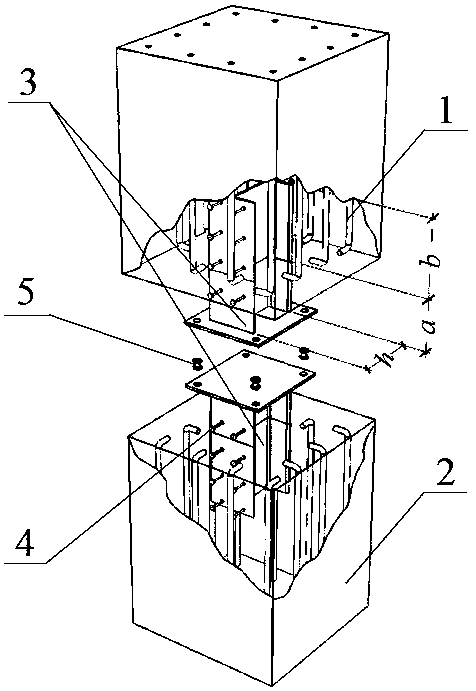

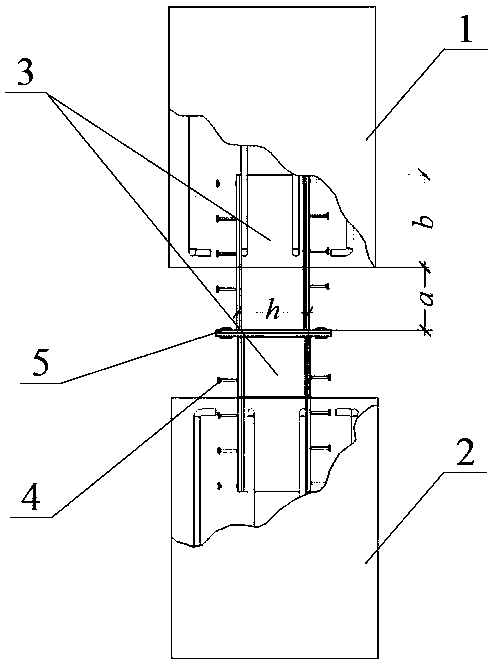

[0016] A prefabricated concrete column-to-column assembly connection node, comprising an upper section precast concrete column 1, a lower section precast concrete column 2, a transfer section steel 3, a shear key 4, and a high-strength bolt 5. The bottom of the precast concrete column 1 in the upper section pre-embeds the transfer section steel 3, the height of the transfer section steel 3 is h, the length of the exposed section is a, the length of the anchored concrete column section is b, and the shear key 4 is arranged; the lower precast concrete column 2 The transfer section steel 3 is pre-embedded at the top, the height of the transfer section steel 3 is h, the length of the exposed section is a, the length of the anchored concrete column section is b, and the shear key 4 is arranged; the transfer section steel 3 of the precast concrete columns 1 and 2 passes through the high-strength The bolts 5 are connected, and the outside of the converted steel 3 is covered with concr...

Embodiment 2

[0018] The difference from Embodiment 1 is that the conversion steel 3 has no connecting end plate, and the conversion steel 3 of the precast concrete columns 1 and 2 are connected by bolts 5 .

Embodiment 3

[0020] The difference from Embodiment 1 is that the conversion steel 3 has no connecting end plate, and the conversion steel 3 is connected by a weld 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com