Motor-driven adjustable centralizer

A motor-driven, centralizer technology, which is applied in drilling equipment, earthwork drilling, drilling pipes, etc., can solve the problems of single diameter of centralizer centralization, inconsistent centralization time, difficulty in lowering, etc., and achieves good centralization effect and simple structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

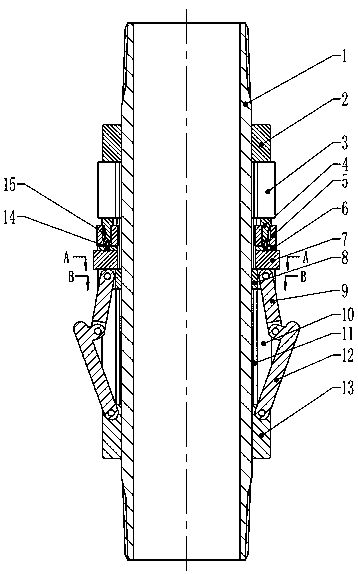

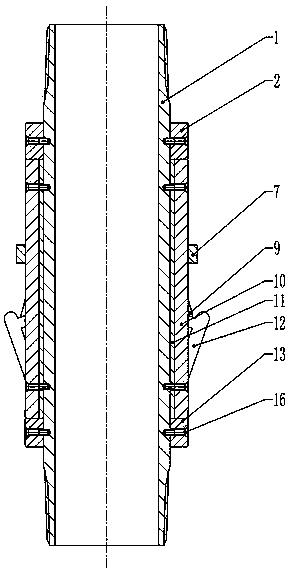

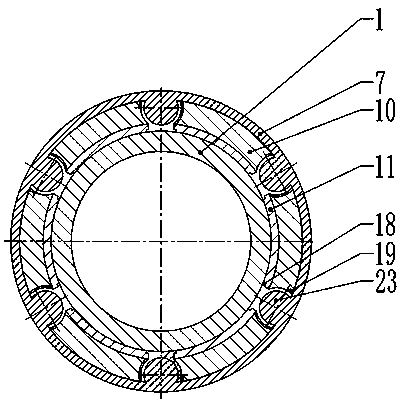

[0021] According to the accompanying drawings, the motor-driven adjustable centralizer mainly consists of a central tube, a motor retaining ring, a motor, a motor shaft, a threaded post, a threaded post end cap, a synchronous ring, a push rod base, a push rod, Composed of threaded arcs, track arcs, centralizing rods, slotted cylindrical head screws, etc., it is characterized in that the motor drives the threaded column to rotate by energizing the motor in the underground casing centralizer, and the threaded column is on a pair of adjacent sides Rotate on the thread, so as to convert the rotary motion of the threaded column into a linear motion, and the linear motion converted by the threaded column will push the centralizing rod to rotate outwards, thereby realizing casing centralization; the track arcs have a total of six pieces, and the six pieces The orbital arcs are evenly arranged outside the central tube along the circumferential direction, and their inner circumference c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com