Quick tenon-and-mortise splicing structural assembly

A technology for structural components and mortise and tenon joints, which is applied in the field of rapid mortise and tenon joint splicing structural components, can solve problems such as affecting the health of construction workers on site, large space occupied by shipping, complicated fixing and connection process, etc. The effect of large, high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] In conjunction with the accompanying drawings of the description, the specific embodiments of the present invention are as follows:

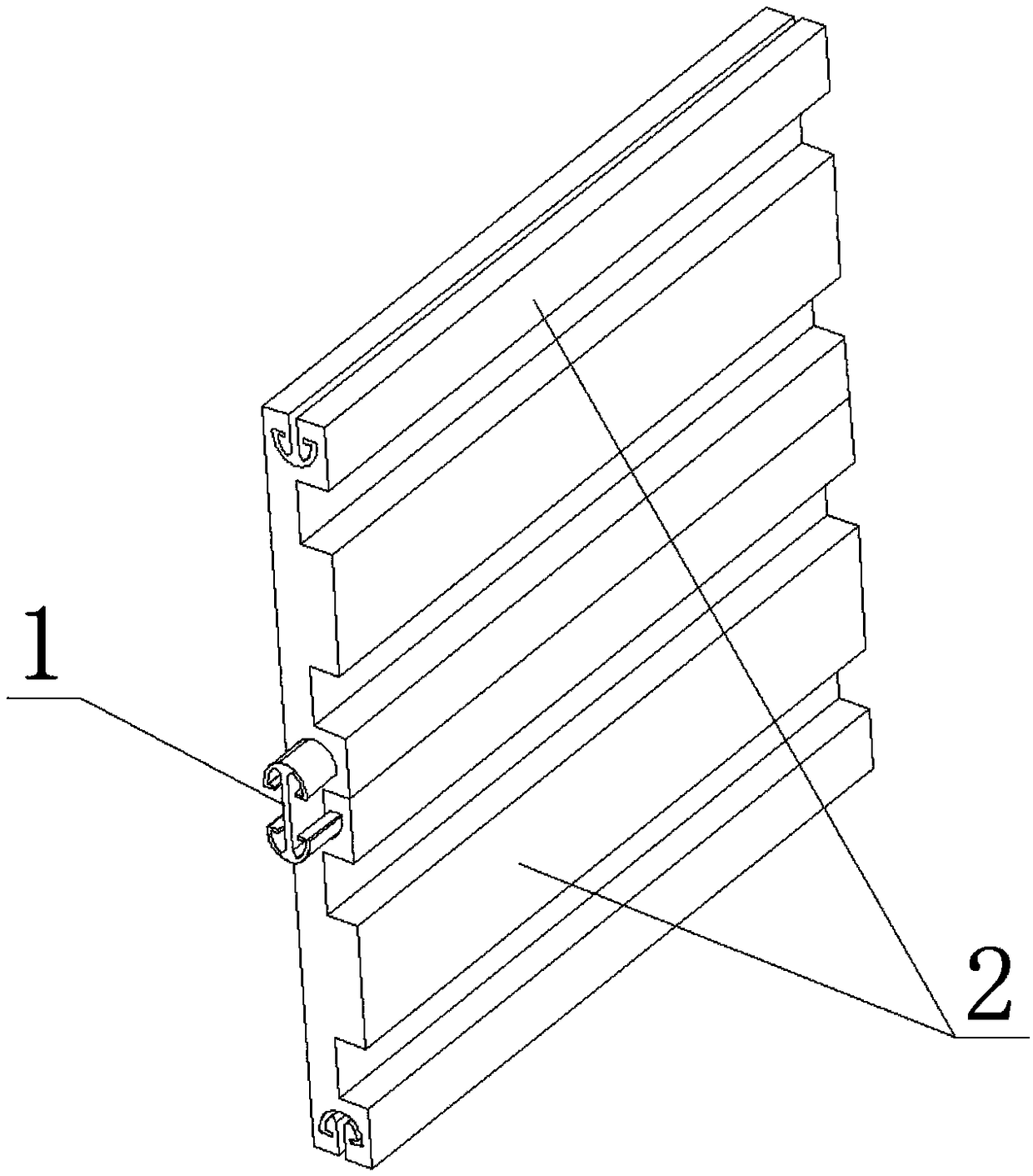

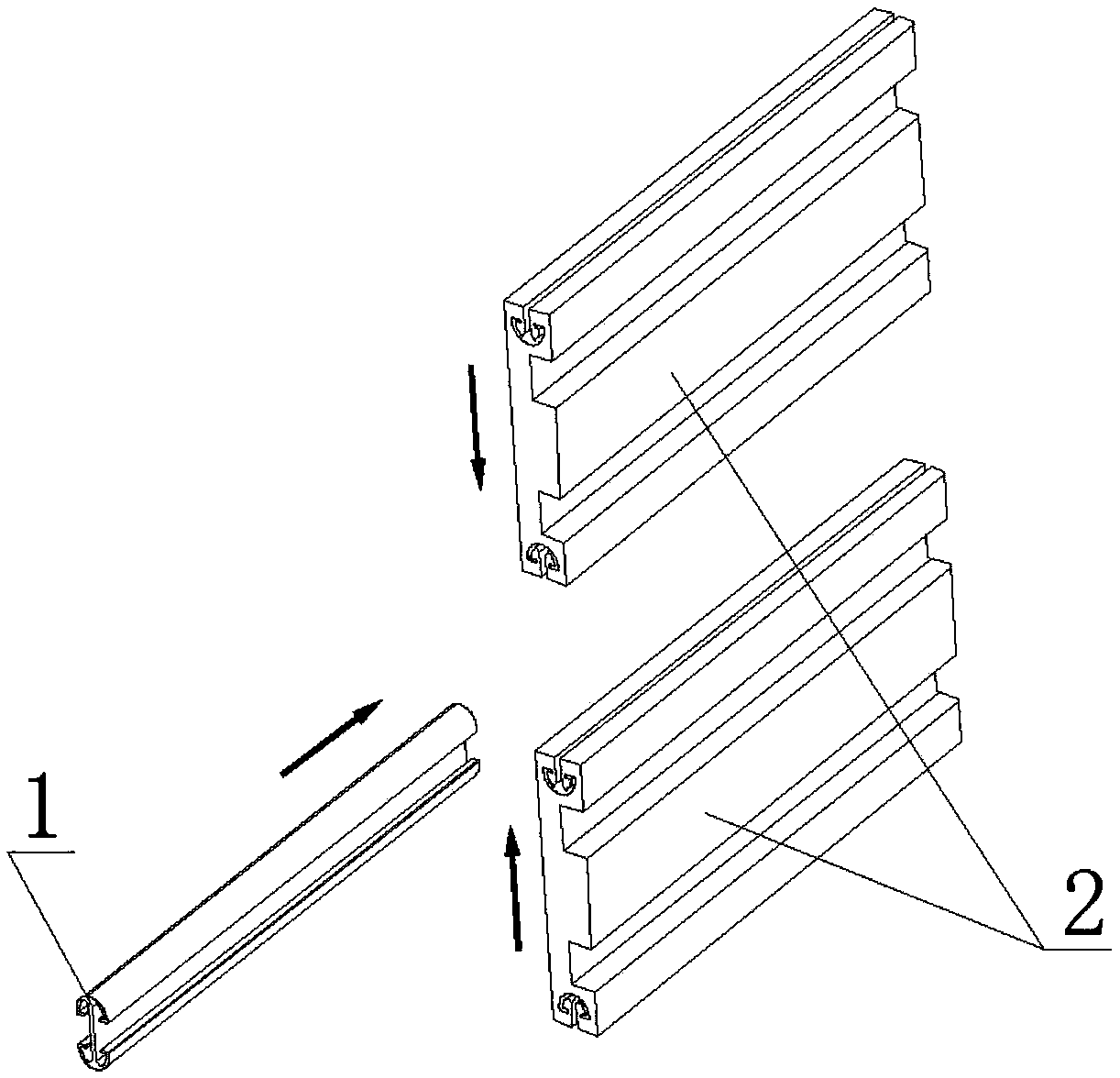

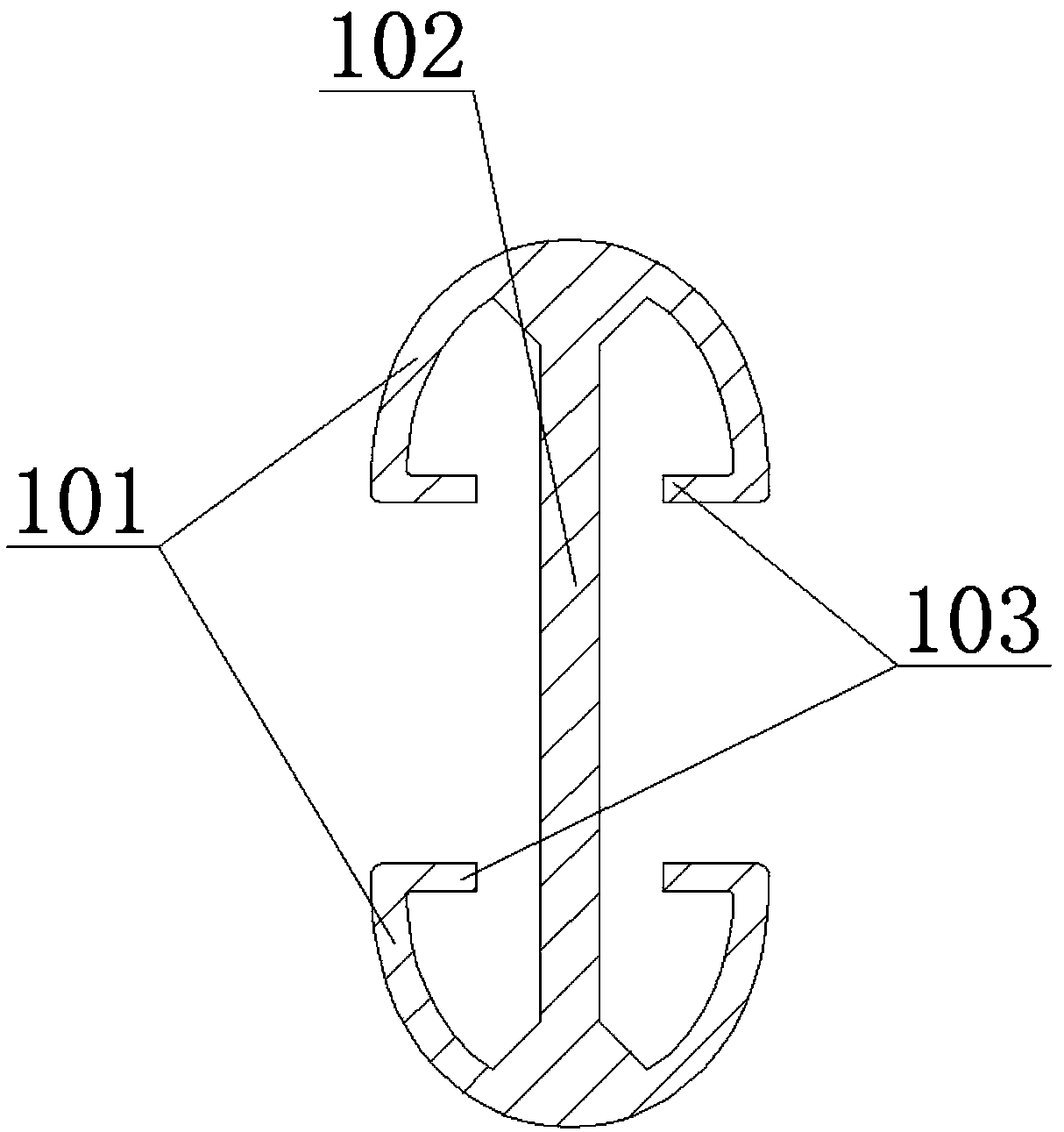

[0016] See the accompanying drawings: a fast mortise and tenon splicing structure assembly, including a mortise joint (1) and a splicing plate (2), characterized in that the mortise joint (1) is elongated as a whole, and the mortise joint (1) ) has anchor-shaped chuck areas (101) on both sides, and the anchor-shaped chuck areas (101) on both sides are connected to each other through the interconnection area (102). The bottom of the anchor-shaped chuck area (101) There is an L-shaped clamping part (103), and the L-shaped clamping part (103) is connected to the anchor-shaped clamping head area (101), and the L-shaped clamping part (103) on the shank connector (1) The inner and outer surfaces of the connecting part of the anchor-shaped clamping head area (101) are smooth without burrs, and the end of the L-shaped clamping part (103) has prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com