Commercial wheel-edge reducer shell for installation of integrated brake caliper brake disc

A technology for brake discs and brake calipers, which is applied in transmission boxes, components with teeth, gear lubrication/cooling, etc., can solve the problems of large volume and weight, complex structure, etc., and achieve small housing volume, small volume, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the best embodiment.

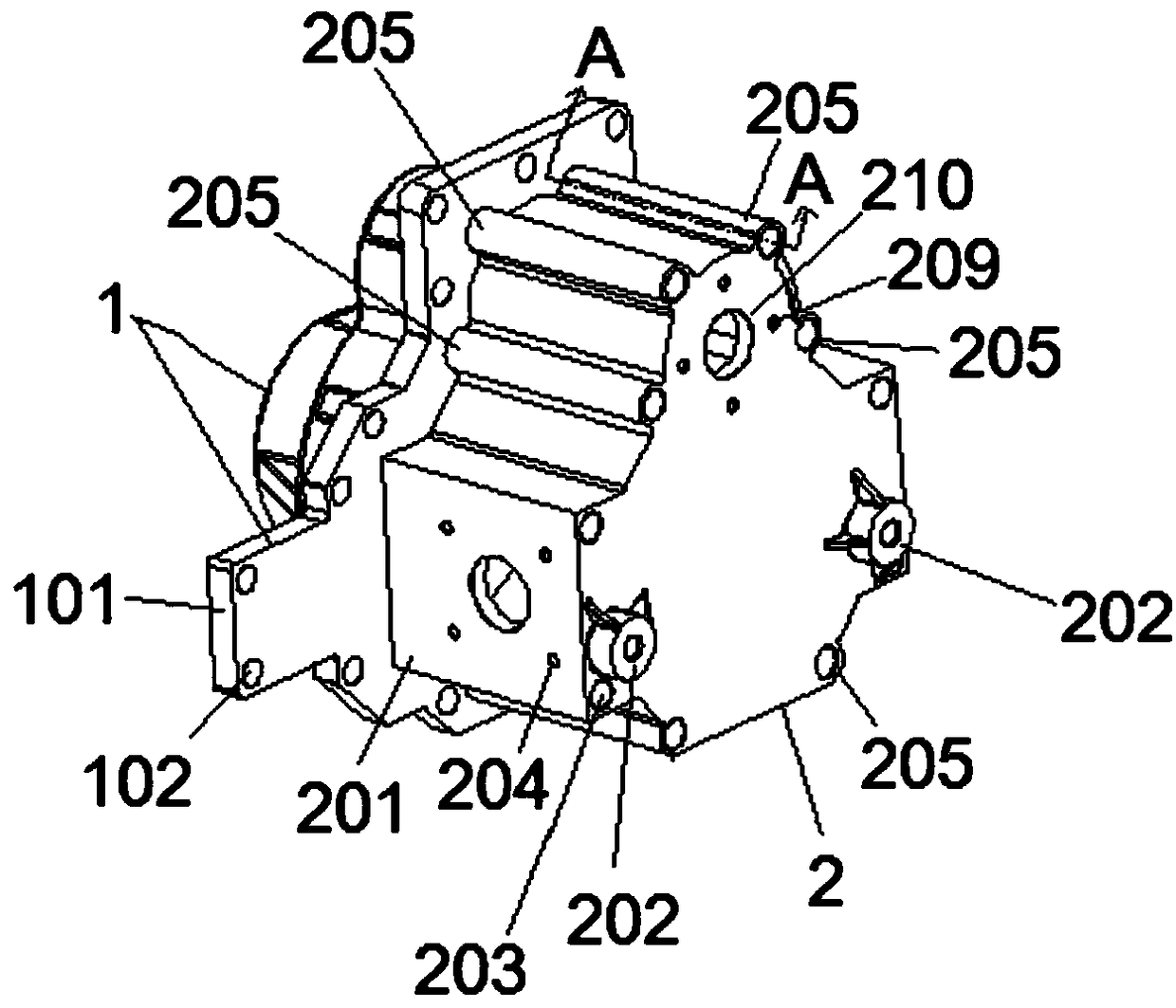

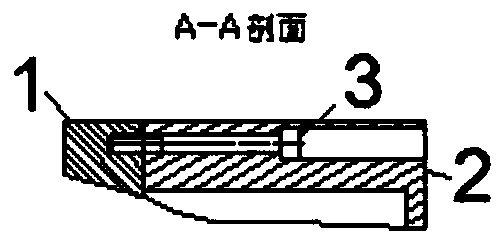

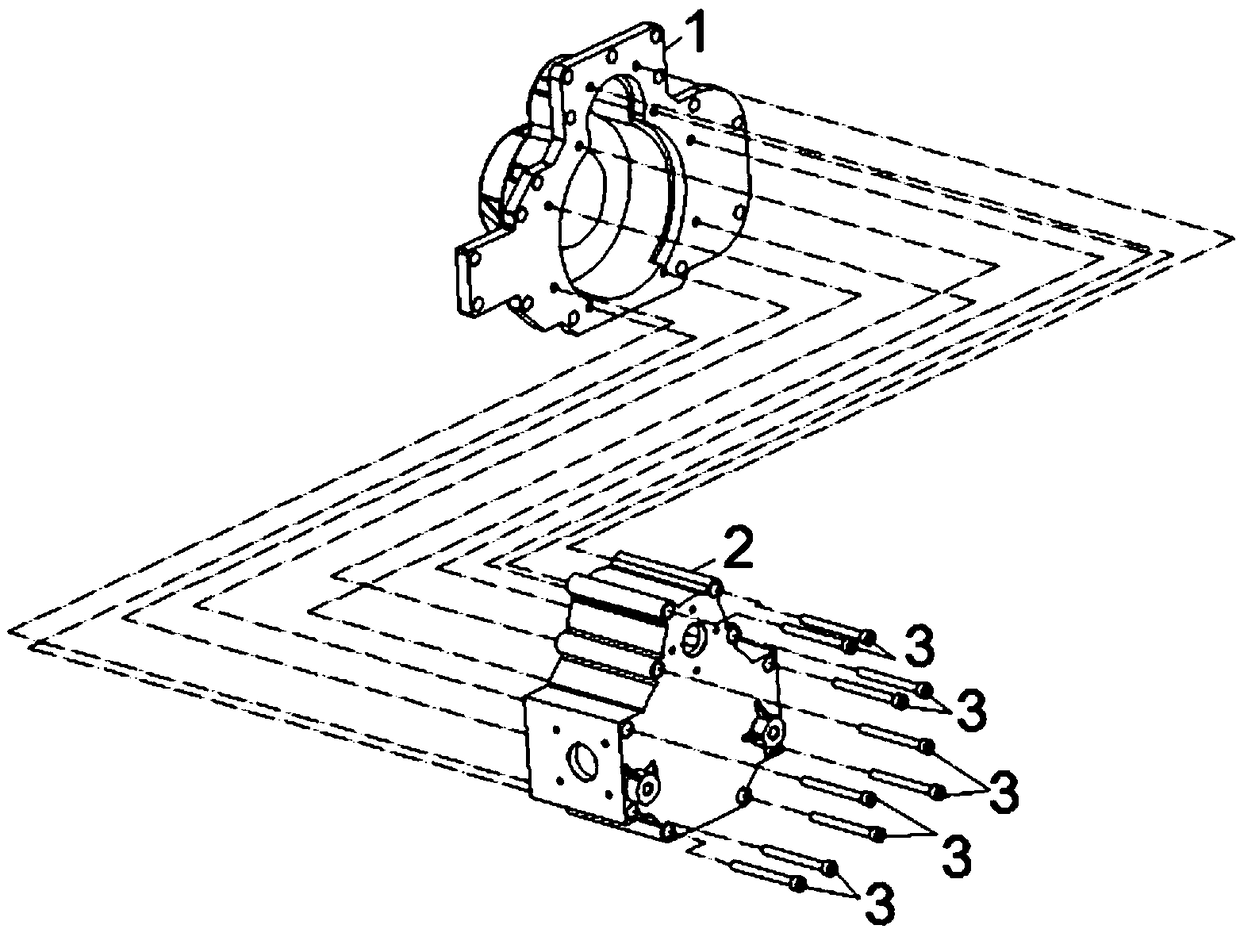

[0029] Such as Figure 1-Figure 4 As shown, the housing of a commercial wheel-side reducer mounted with an integrated brake caliper brake disc has a split design and is composed of a first housing 1 and a second housing 2 in a sealed connection; the first housing 1 includes a web 101 And the supporting boss 104 provided on the web 101, it also includes a cylinder 105, one end of the cylinder 105 is connected to the supporting boss 104, the other end of the cylinder 105 is the cylinder flange surface 108, the web 101, The supporting boss 104 and the cylinder 105 are integrally formed to form a first cavity; the outer wall of the supporting boss 104 is provided with a first rib 103 connected to the web 101, and the outer wall of the cylinder 105 is provided with a supporting boss 104 The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com