Special novel furnace for refining bamboo salt and black bamboo salt

A technology of purple bamboo salt and bamboo salt, applied in furnaces, crucible furnaces, furnace types, etc., can solve problems such as gasification and evaporation of bamboo salt, accidents, and kiln pressure out of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will describe in detail with reference to the drawings in the embodiments of the present invention. In addition, the bamboo salt in this article includes ordinary bamboo salt and purple bamboo salt.

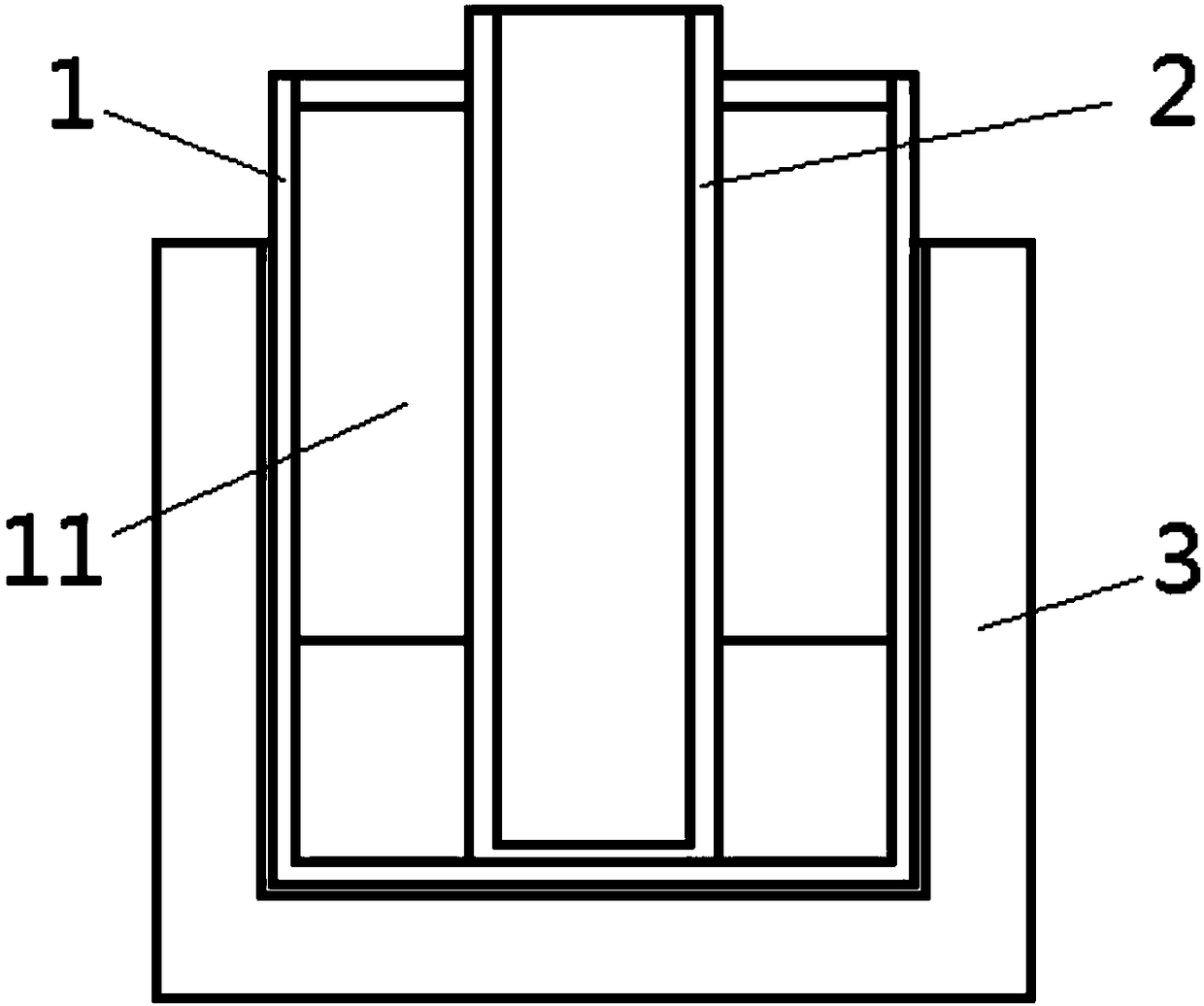

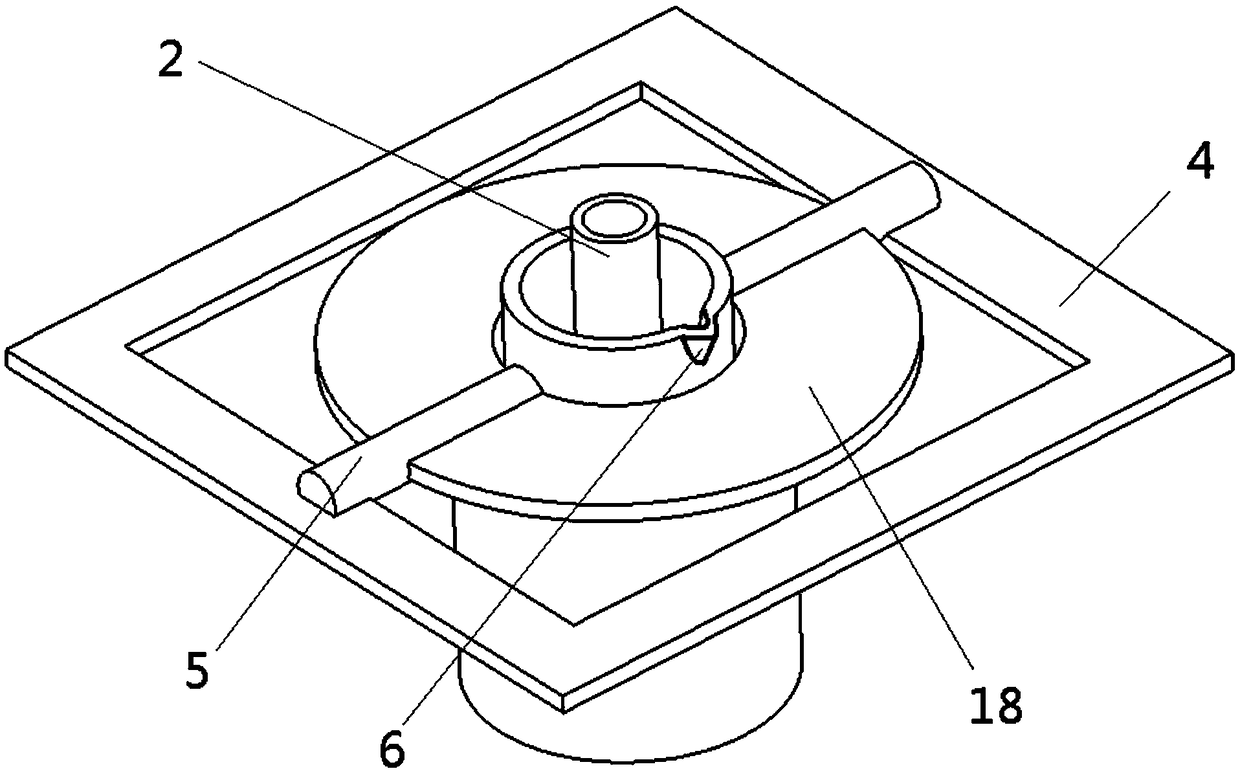

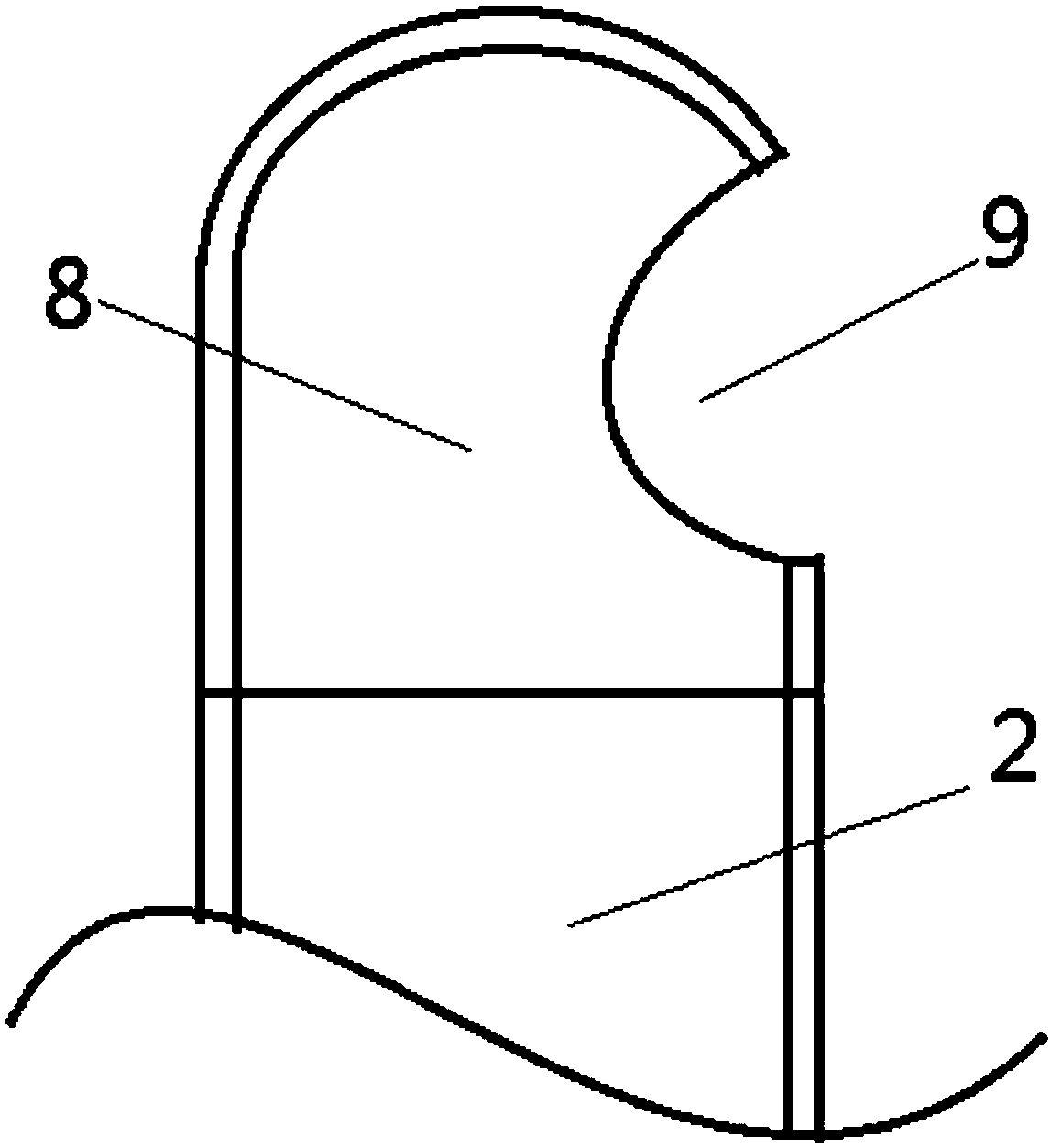

[0032] see figure 1 , figure 2 , image 3 , a special new-style kiln for refining bamboo salt and purple bamboo salt, characterized in that it comprises: a bamboo salt crucible 1, the bamboo salt crucible 1 is a columnar cavity structure arranged vertically, and the top of the bamboo salt crucible 1 is provided with an open mouth; molten iron crucible 2, molten iron crucible 2 is a columnar cavity structure coaxially nested in bamboo salt crucible 1, the outside of the bottom of molten iron crucible 2 is connected and fixed with the bottom of bamboo salt crucible 1; the top of molten iron crucible 2 is provided with an opening The intermediate frequency furnace 3 is vertically provided with a cylindrical furnace chamber inside the intermediate frequency f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com