Calibration device and method for linear temperature sensor array

A temperature sensor and linear sensor technology, applied in thermometers, measuring devices, thermometer testing/calibration, etc., can solve the problems of being easily affected by bending stress, low precision, and poor consistency, and achieve simple devices, simple calibration devices, and calibration accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

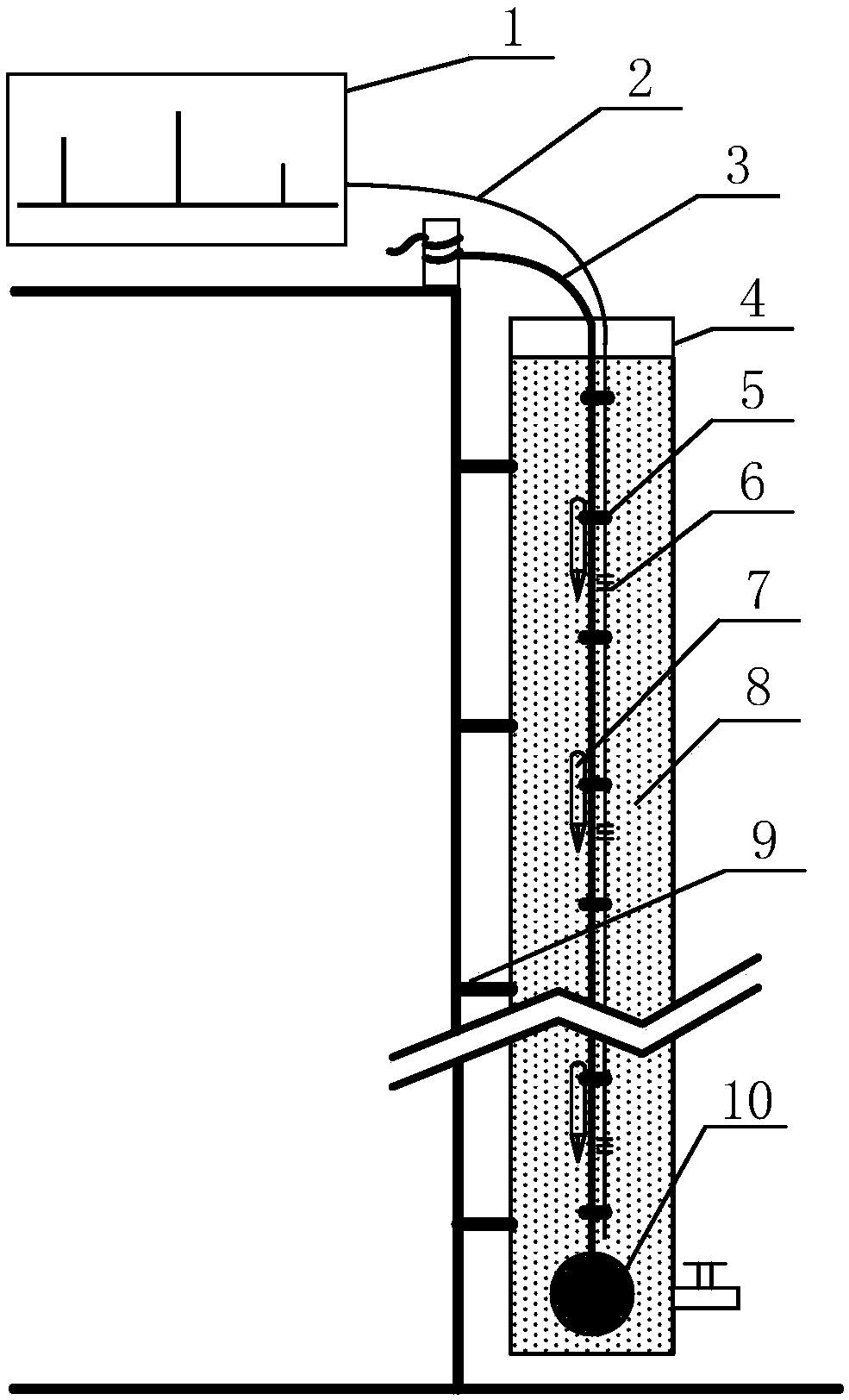

[0034] Such as figure 1 As shown, a calibration device for a linear temperature sensor includes a hard tube 4 , a linear temperature sensor array 2 , a thermometer 7 , a demodulator 1 , and a fixing frame 9 .

[0035] The bottom end of the hard tube 4 is sealed with a valve and the top is open; the fixed frame 9 vertically fixes the hard tube 4;

[0036] The hard tube 4 is filled with a liquid heat transfer medium 8;

[0037] One end of the linear temperature sensor array 2 is placed freely downward along the opening at the top of the hard tube 4, and the other end of the linear temperature sensor array 2 is connected to the demodulator 1;

[0038] The thermometer 7 is fixed in parallel with the sensing points on the linear temperature sensor array 2 .

[0039] The liquid heat transfer medium 8 is water or oil, the temperature of which is changed by the ambient temperature outside the hard tube 4 .

[0040] The linear temperature sensor array 2 is a fiber grating array.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com