Train crack detection device

A crack detection and train technology, applied in the direction of material magnetic variables, etc., can solve the problems of low detection efficiency, high detection environment requirements, high labor intensity of hollow shaft detection, etc., and achieve the effect of high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

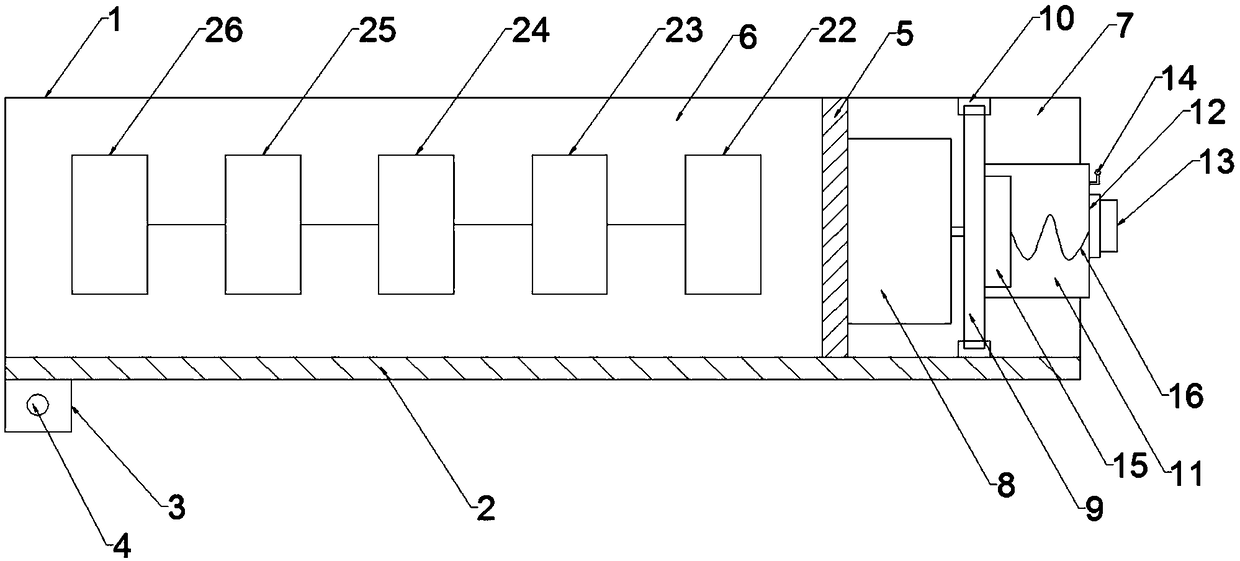

[0019] Such as Figure 1-2 As shown, a crack detection device for a train comprises a fixed barrel 1, the bottom of the fixed barrel 1 is provided with a rack 2 along the length direction of the fixed barrel 1, and a gear 3 meshing with the rack 2 is arranged below the rack 2. 3 connected with the first motor 4.

[0020] The fixed barrel 1 is provided with a baffle 5, and the baffle 5 divides the fixed barrel 1 into a first chamber 6 and a second chamber 7; the second chamber 7 is provided with a second motor 8, and the second motor 8 Fixed on the baffle plate 5, the output shaft of the second motor 8 is connected with a rotating disk 9; the fixed barrel 1 is provided with a rotating groove 10 along the circumferential direction of the fixed barrel 1, and the rotating disk 9 is located in the rotating groove 10 And can rotate along the rotating groove 10, the rotating barrel 11 is fixed on the rotating disk 9, the end of the rotating barrel 11 runs through the fixed barrel 1 ...

Embodiment 2

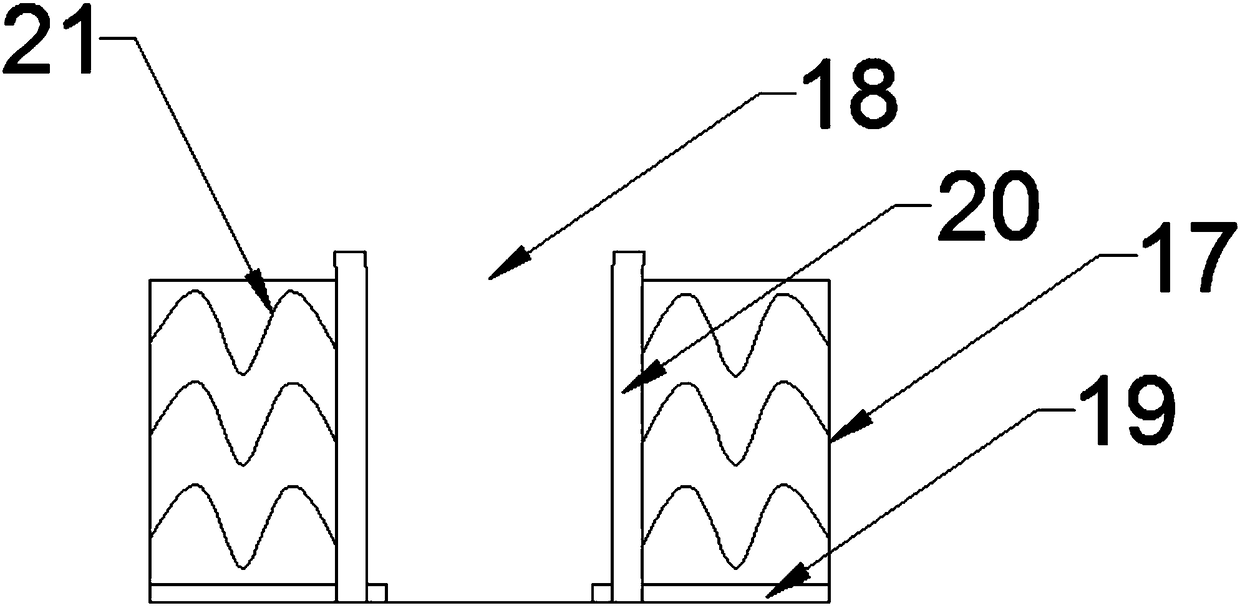

[0023] On the basis of Example 1, such as figure 2 As shown, the fixed assembly includes a hollow cylinder 17, the hollow cylinder 17 is fixed to the fixed port 12 and communicates with the rotating bucket 11, the top of the hollow cylinder 17 is provided with a probe inlet 18, and the bottom of the hollow cylinder 17 is uniformly arranged along the radial direction of the hollow cylinder 17. There are several moving grooves 19, and vertical baffles 20 are arranged in the moving grooves 19, and the top of the vertical baffles 20 passes through the probe inlet 18 and is inclined outside; a spring 21;

[0024] When using this embodiment, the fixed part of the probe 13 is placed between the vertical baffles 20, and the spring 21 gives an elastic force to the vertical baffle 20, thereby fixing the probe 13 stably; the top of the vertical baffle 20 passes through the probe 13 The entrance is inclined outwards, so that the size of the entrance of the probe 13 can be increased to e...

Embodiment 3

[0026] On the basis of embodiment 1-2, such as Figure 1-2 As shown, the probe 13 is connected with a signal amplifier 22, and the signal amplifier 22 is connected with a peak hold circuit 23, and the peak hold circuit 23 is connected with an A / D converter 24, and the A / D converter 24 is connected with a stand-alone controller 25, and the stand-alone Controller 25 is connected with alarm 26; Between described probe 13, signal amplifier 22, peak hold circuit 23, A / D converter 24, stand-alone controller 25 and alarm 26, connect by signal line, described signal amplifier 22 , peak hold circuit 23, A / D converter 24, stand-alone controller 25 and alarm 26 are all located in the first chamber 6;

[0027] When this embodiment is used, the front device 15 generates an eddy current on the inner surface of the hollow shaft through the probe 13, and the eddy current simultaneously generates a magnetic field opposite to the original magnetic field, and offsets part of the original magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com