A fpc structure for reducing AC resistance

A technology of AC resistors and coils, applied in circuits, inductors, electrical components, etc., can solve the problems of large heat generation and low coil transmission efficiency, and achieve the goals of reducing current resistance, improving conversion efficiency and temperature rise data, and preventing short circuits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

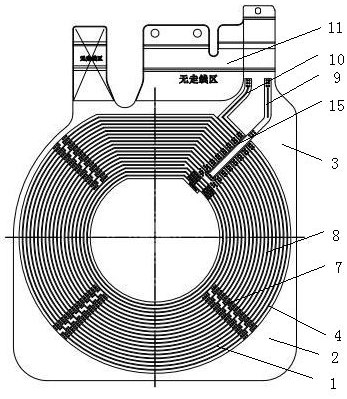

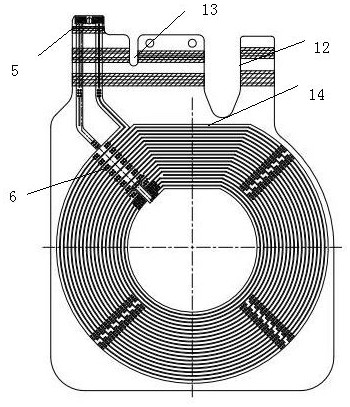

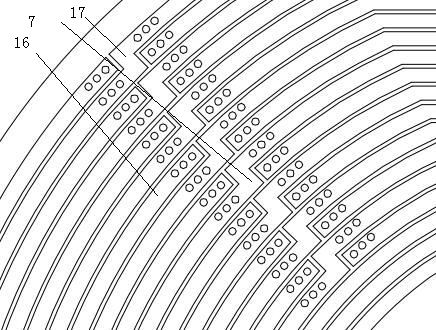

[0029] Such as figure 1 , figure 2 , image 3 As shown, a kind of reducing AC resistance FPC structure provided by the present invention includes: a coil 1 and an FPC fixed plate 2 with an n-turn coil layer 16, the coil is installed on the FPC fixed plate, and the fixed plate positioned at the outside of the coil is equipped with Protective film area 3. The n-turn coil and the protective film constitute the FPC coil 4 . A welding pad 5 is provided on the outer edge of the FPC fixing board, and the outgoing line end or incoming line end is connected to the welding pad through a foil wire. The FPC fixed board is provided with via holes 6, and each coil layer is sequentially connected in parallel through the via holes.

[0030] The coil has m slots 7 arranged in the radial direction of the coil to divide the coil into m routing areas 8, wherein the coil layer of the outer ring on one side of the slot is connected to the adjacent slot by a connecting piece. For the coil laye...

Embodiment 2

[0034] An FPC structure for reducing AC resistance provided by the present invention includes: a coil with n turns of coil layer, and the coil has m slots arranged radially along the coil to separate the coil into m+1 routing areas, wherein , the coil layer of the outer ring on one side of the slot is connected to the coil layer of the inner ring on the other side adjacent to the slot through a connecting piece, so that m and n are integers greater than 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com