A lithium paste battery cell having a supporting current guiding cable and a lithium paste battery

A slurry battery and cell technology, which is used in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, etc., can solve problems affecting battery performance, unfavorable battery injection, uniform infiltration of liquid electrolyte, and limited electrode spacing. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described through embodiments below in conjunction with the accompanying drawings.

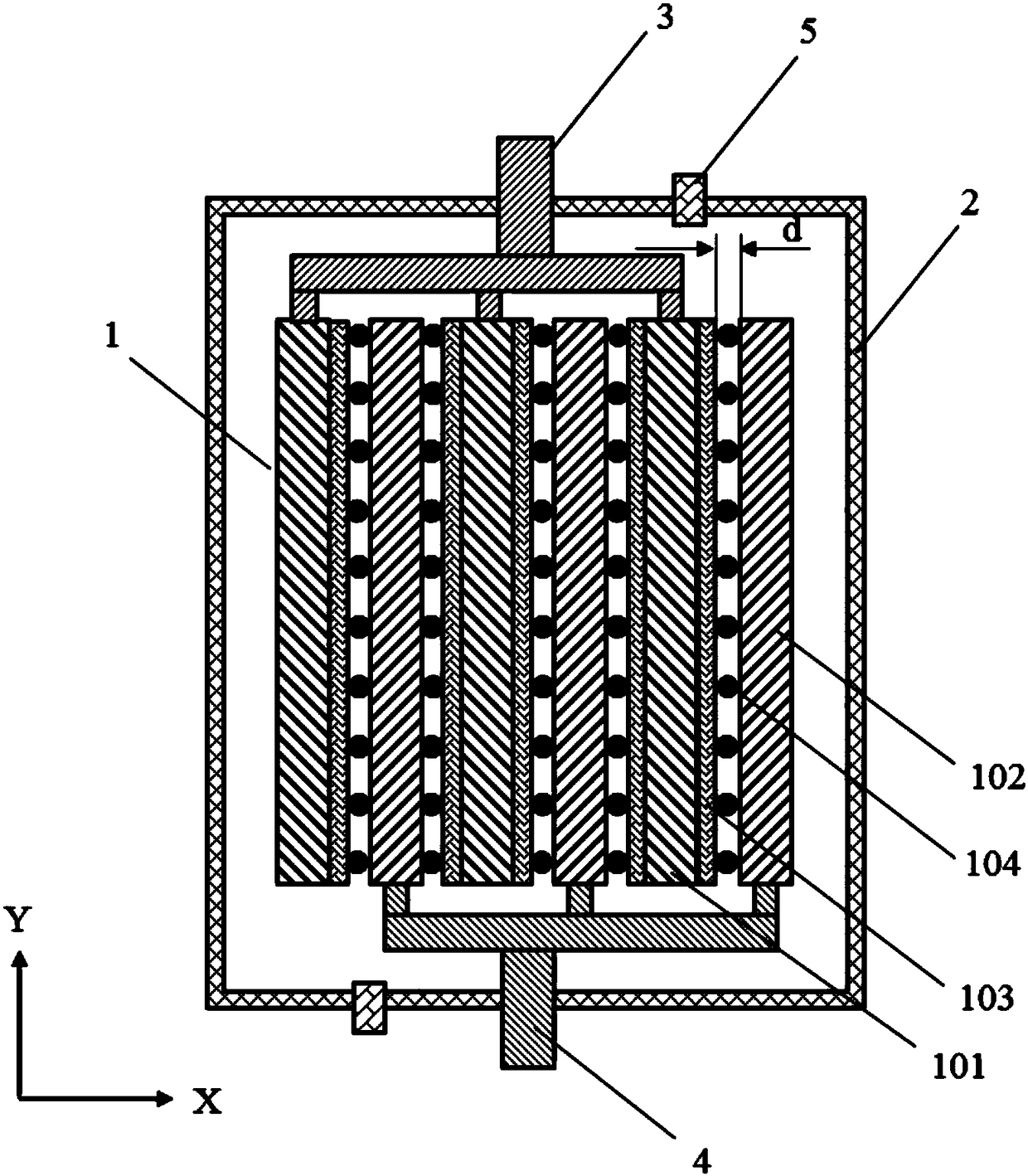

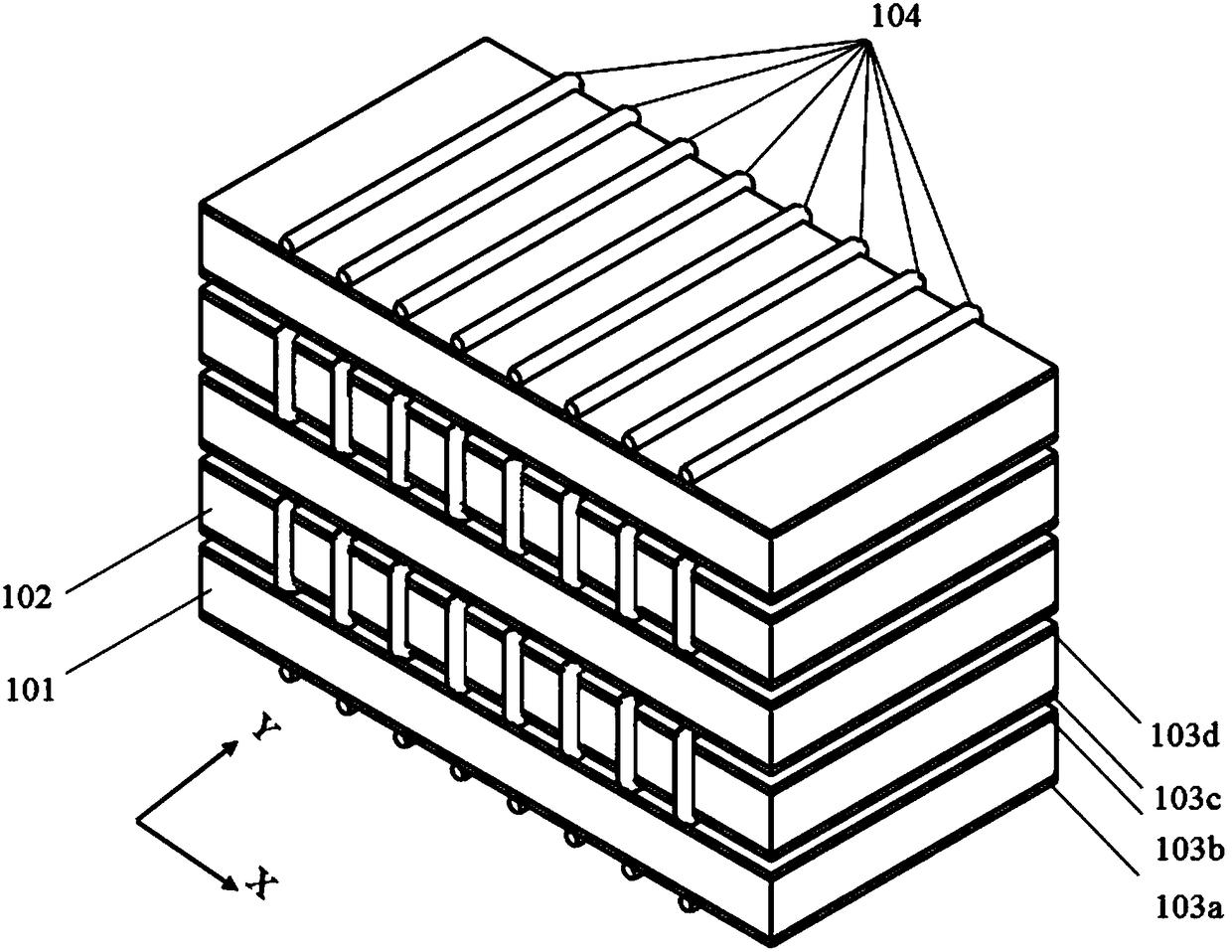

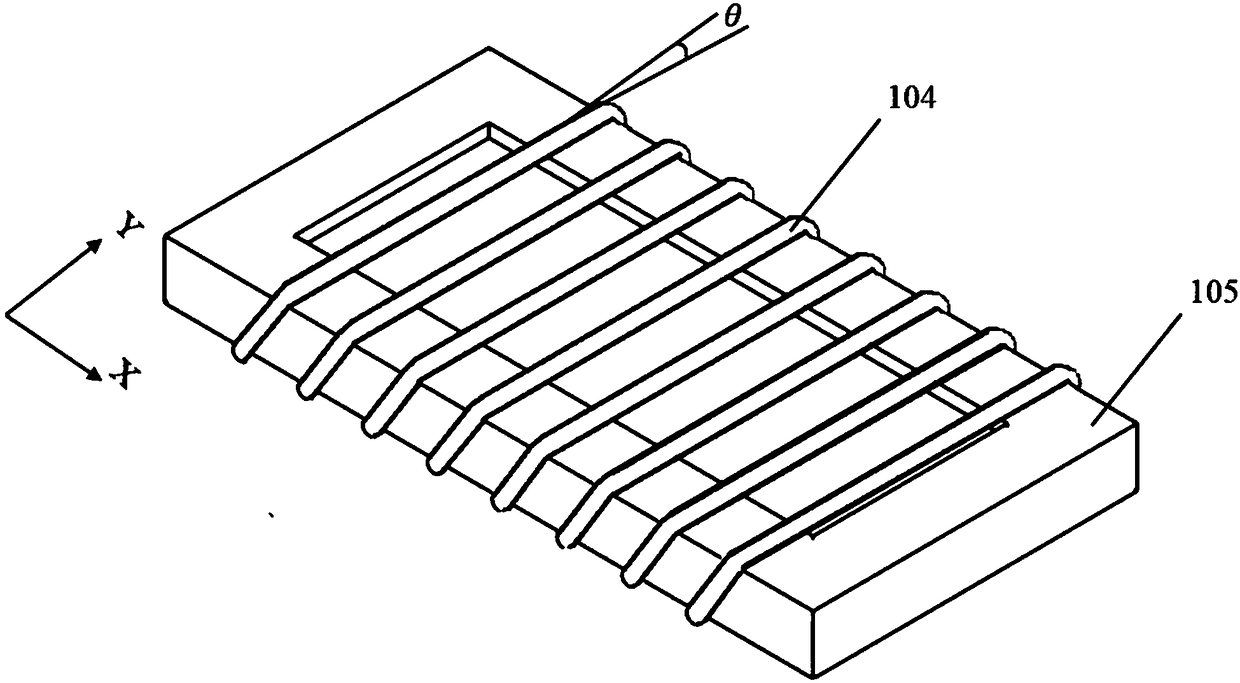

[0050] figure 1 It is a schematic cross-sectional view of a lithium slurry battery according to the present invention. The lithium slurry battery includes a lithium slurry battery cell 1 , a battery casing 2 , a positive terminal 3 , a negative terminal 4 and a liquid injection port 5 . The lithium slurry battery cell 1 includes a positive electrode sheet 101, a negative electrode sheet 102, an isolation layer 103 and a supporting guide cable 104, wherein the positive electrode sheet 101 and the negative electrode sheet 102 are cross-stacked, and the isolation layer 103 is in a manner close to the positive electrode sheet 101 It is arranged between the positive electrode sheet 101 and the negative electrode sheet 102, and the supporting current guiding cable 104 is arranged between the isolation layer 103 and the negative electrode sheet 102 so as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com