A miniaturized crown spring type socket joint

A crown spring, interference fit technology, applied in electrical components, coupling devices, parts of connecting devices, etc., can solve the problems of reducing the reliability of signal transmission, loosening of protective tubes and pins, and reducing production efficiency. Low risk of unwanted entry, stable contact resistance, and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

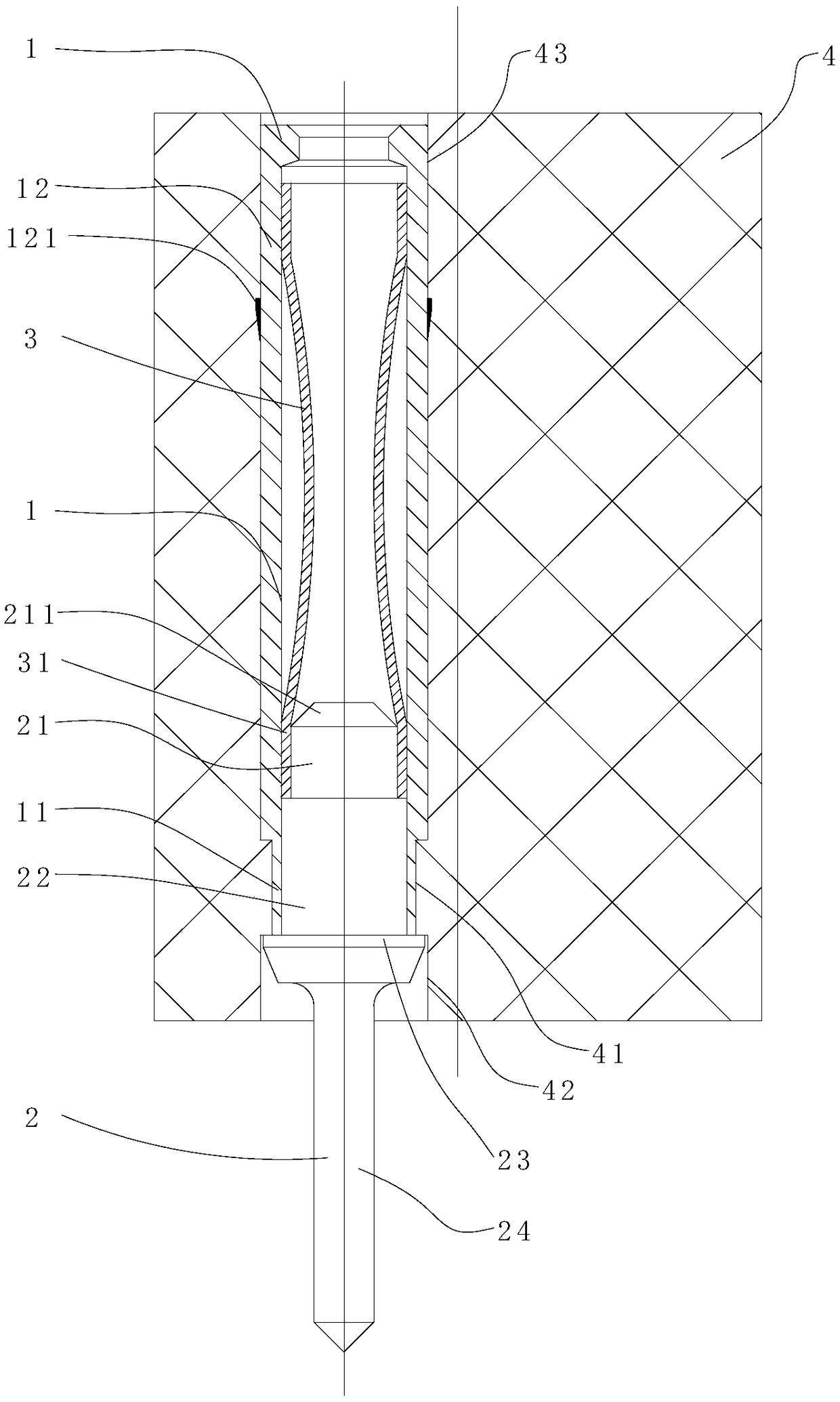

[0023] Such as figure 1 A miniaturized crown spring socket assembly shown in the figure includes a protective tube 1, a pin 2, and a contact ring 3. The protective tube 1 and pin 2 are made of copper alloy with excellent electrical conductivity, and the crown spring contact ring 3 It is a crown spring type contact ring, made of beryllium copper alloy; the protective tube 1 is set and fixed in the base 4, the protective tube 1 is equipped with a contact ring 3, and the pin 2 is set at the rear end of the protective tube 1 and the contact ring 3 ; Transition fit between the protective tube 1 and the base 4, the pin 2 is in contact with the protective tube 1, the contact ring 3 and the base 4 at the same time, and the contact surface of the pin 2 and the base 4 is stabbed with a pin 23 interference fit.

[0024] Further, the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com