The Ventilation and Cooling Structure of Auxiliary Slots of Generators in Series and Parallel with Variable Section

A technology of auxiliary slot ventilation and variable cross-section, which is applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of wind energy consumption, uneven distribution of air volume, and inability to cool the generator well, and achieve Ensure the wind speed and reduce the temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The embodiment of the present invention provides a series-parallel variable cross-section generator auxiliary tank ventilation and cooling structure, which ensures the safe and reliable operation of the generator and improves the operation stability of the generator.

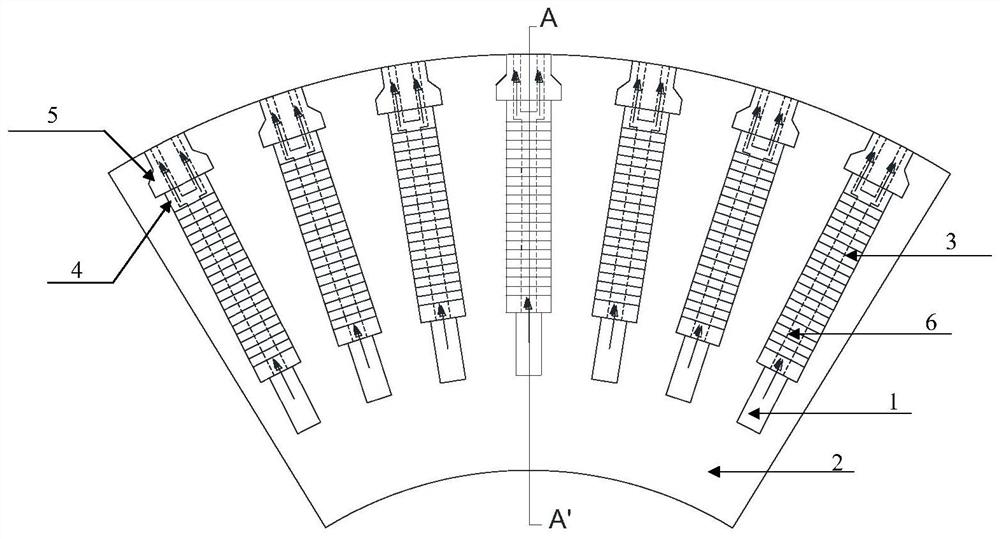

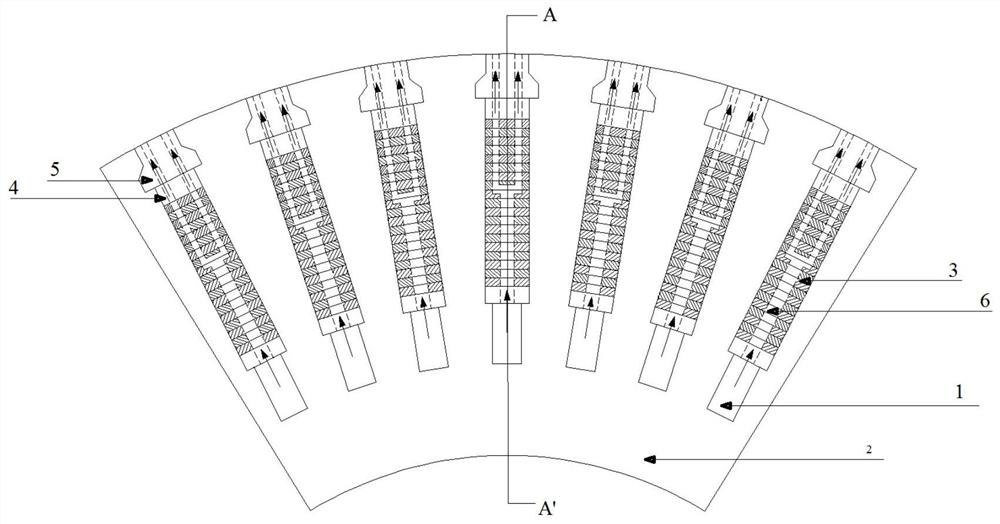

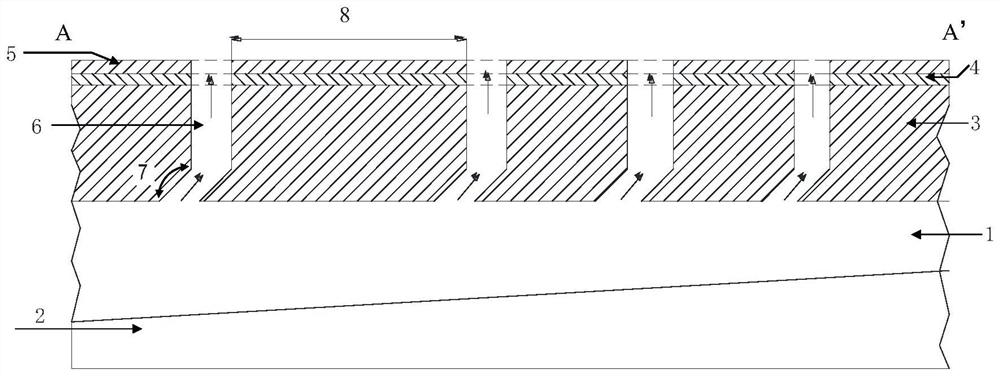

[0039] A schematic diagram of a series-parallel variable-section generator sub-slot ventilation and cooling structure provided by an embodiment of the present invention is as follows: Figure 1-2 As shown, the structure includes: auxiliary slot 1 , rotor core 2 , rotor winding 3 , rotor wedge pad 4 , rotor slot wedge 5 and series-parallel ventilation ditch 6 . The auxiliary slot 1 is placed at the bottom of the rotor winding 3, the series-parallel ventilation groove 6 communicates with the rotor slot wedge 5 and the auxiliary slot 1, and the connection between the rotor winding 3 and the rotor slot wedge 5 The rotor wedge pads 4 are arranged between them. The series-parallel ventilation grooves 6 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com