A high-precision integrated high-frequency high-voltage power supply

A high-frequency high-voltage power supply, high-precision technology, used in electrical components, adjusting electrical variables, instruments, etc., can solve the problems of overvoltage burnout, slow response, easy overcurrent damage, etc., and achieve reasonable installation and heat dissipation. The effect of reducing ripple factor and preventing voltage overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

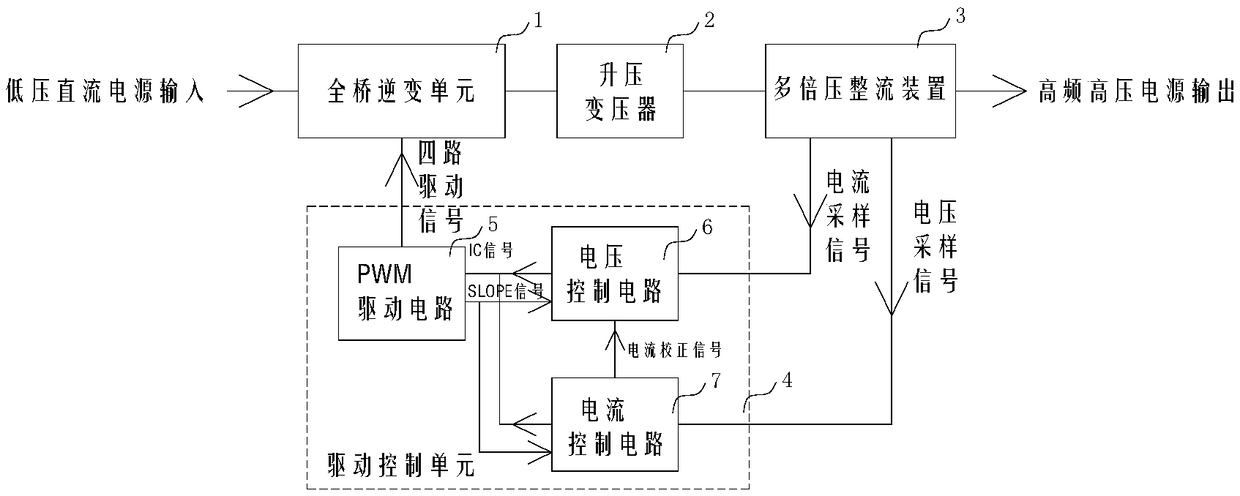

[0052] like figure 1 As shown, a high-precision integrated high-frequency high-voltage power supply includes a full-bridge inverter unit 1, a step-up transformer 2, and a multi-voltage rectifier 3 sequentially connected from a low-voltage DC input terminal to a high-frequency high-voltage output terminal; it also includes A drive control unit 4 for driving the full-bridge inverter unit; the drive control unit 4 includes a PWM drive circuit 5 .

[0053] The drive control unit 4 also includes a voltage control circuit 6 and a current control circuit 7 connected to the PWM drive circuit 5; The voltage acquisition end of the voltage acquisition end is connected with the current acquisition end, and its output end jointly outputs the pulse width adjustment signal IC to the PWM driving circuit 5 .

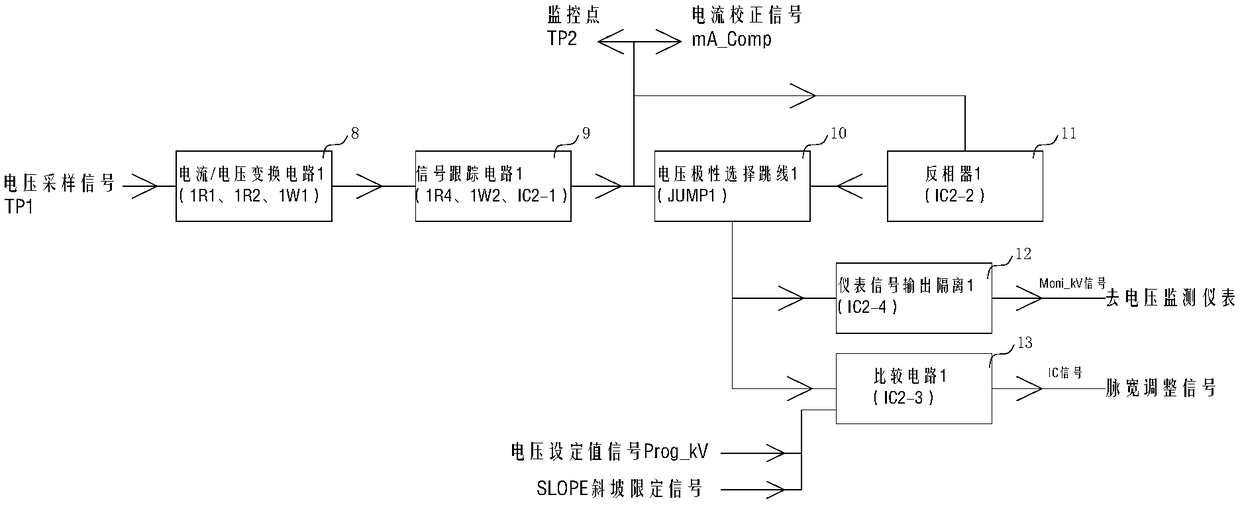

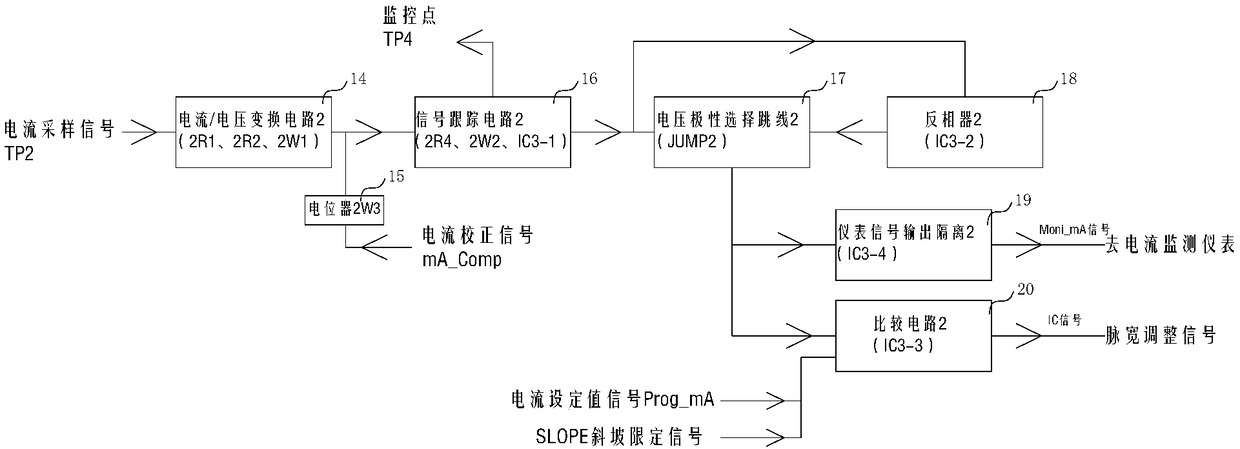

[0054] like figure 2 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com