Turbomachine housing

A technology for turbine shells and shells, which is applied to mechanical equipment, engine components, machines/engines, etc., and can solve the problems of offsetting the tightness of the flange connection, the influence of the tightness of the flange connection, and unfavorable lever conditions. achieve good tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

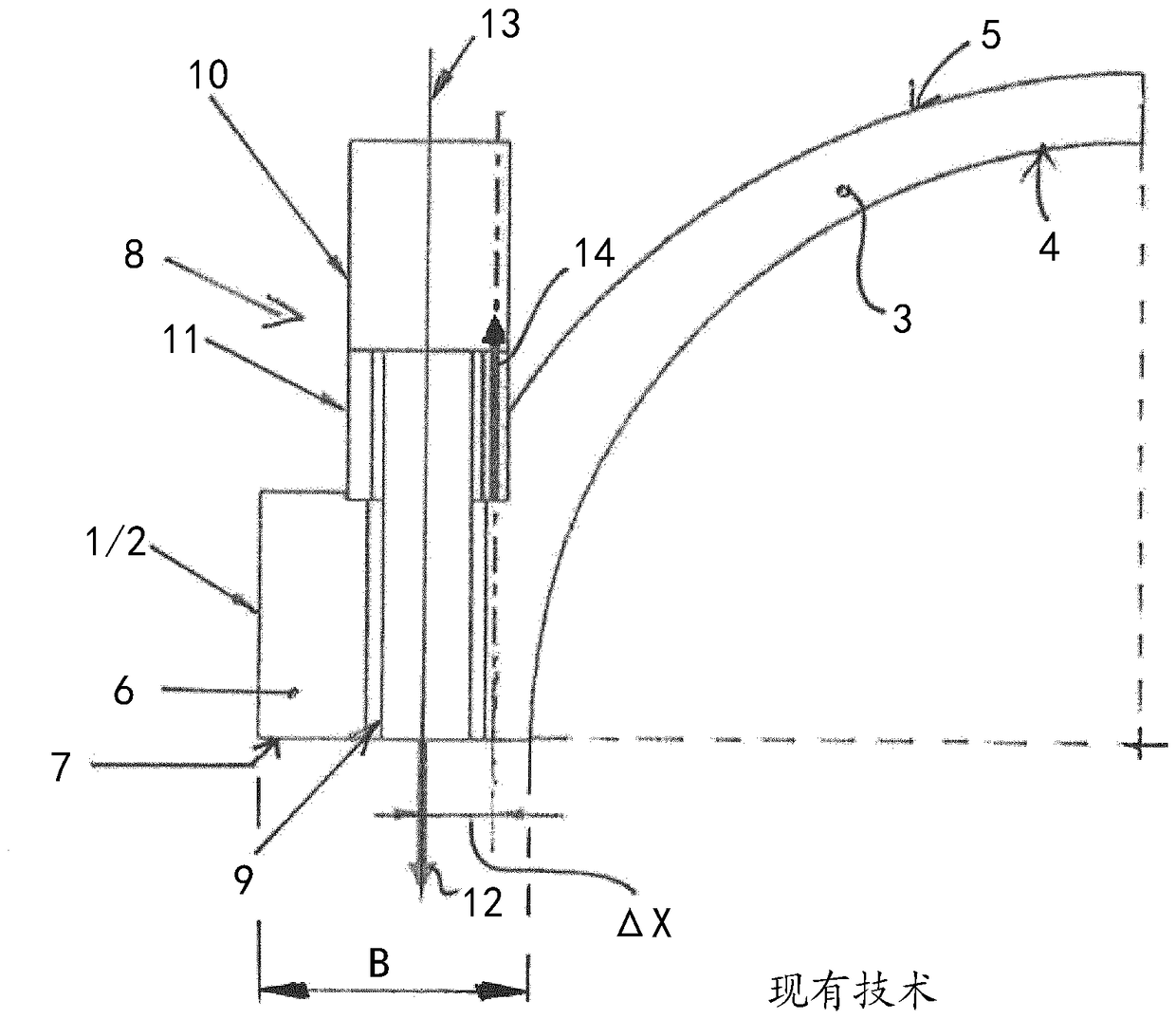

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention relates to a turbine housing, in particular a steam turbine housing.

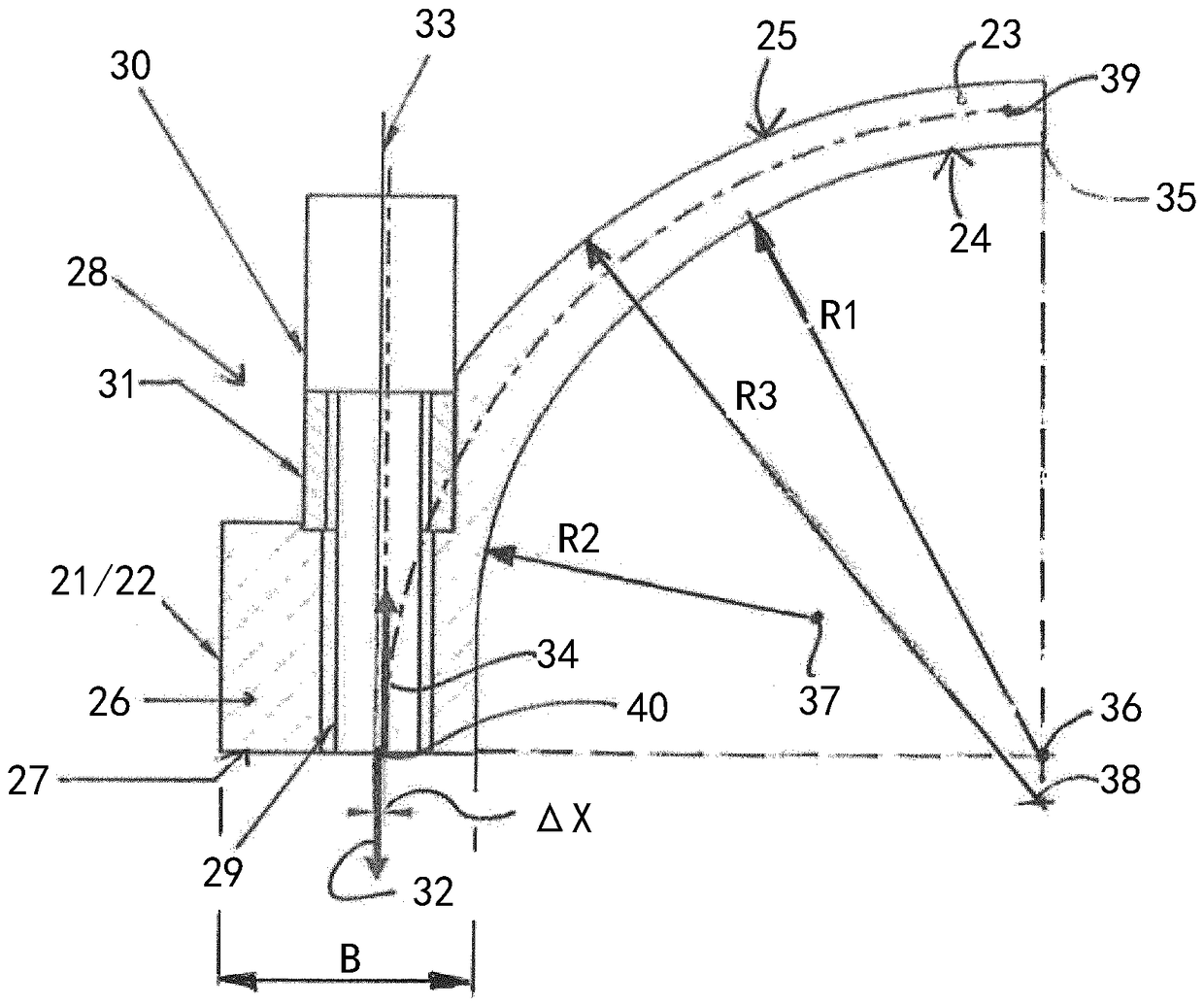

[0018] figure 2 A preferred exemplary embodiment of the turbine housing 21 according to the invention is shown in the region of the second cover-like housing part 22 which is connected to the bottom of the turbine housing 21. The first lower shaped housing part is shown. Shown is a curved wall 23 of a cap-like cylindrical shell-like housing part 22 comprising an inner side 24 and an outer side 25 which are curved in cross-section.

[0019] The illustrated cover-shaped housing part 22 of the turbine housing 21 comprises a flange 26 with a flange surface 27 , wherein the flange surface 27 of the flange 26 of the cover-shaped housing part 22 passes through the turbine housing 21 The not shown lower housing parts are connected to corresponding flange surfaces, and wherein these housing parts are then connected to each other via screw connections 28 . Each of the bolted connections 28 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com