Spring plate type drying cylinder supporting ring welding tool and method for asphalt mixture stirring device

A technology of asphalt mixture and mixing equipment, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of high cost, and achieve the effects of low processing cost, simple structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

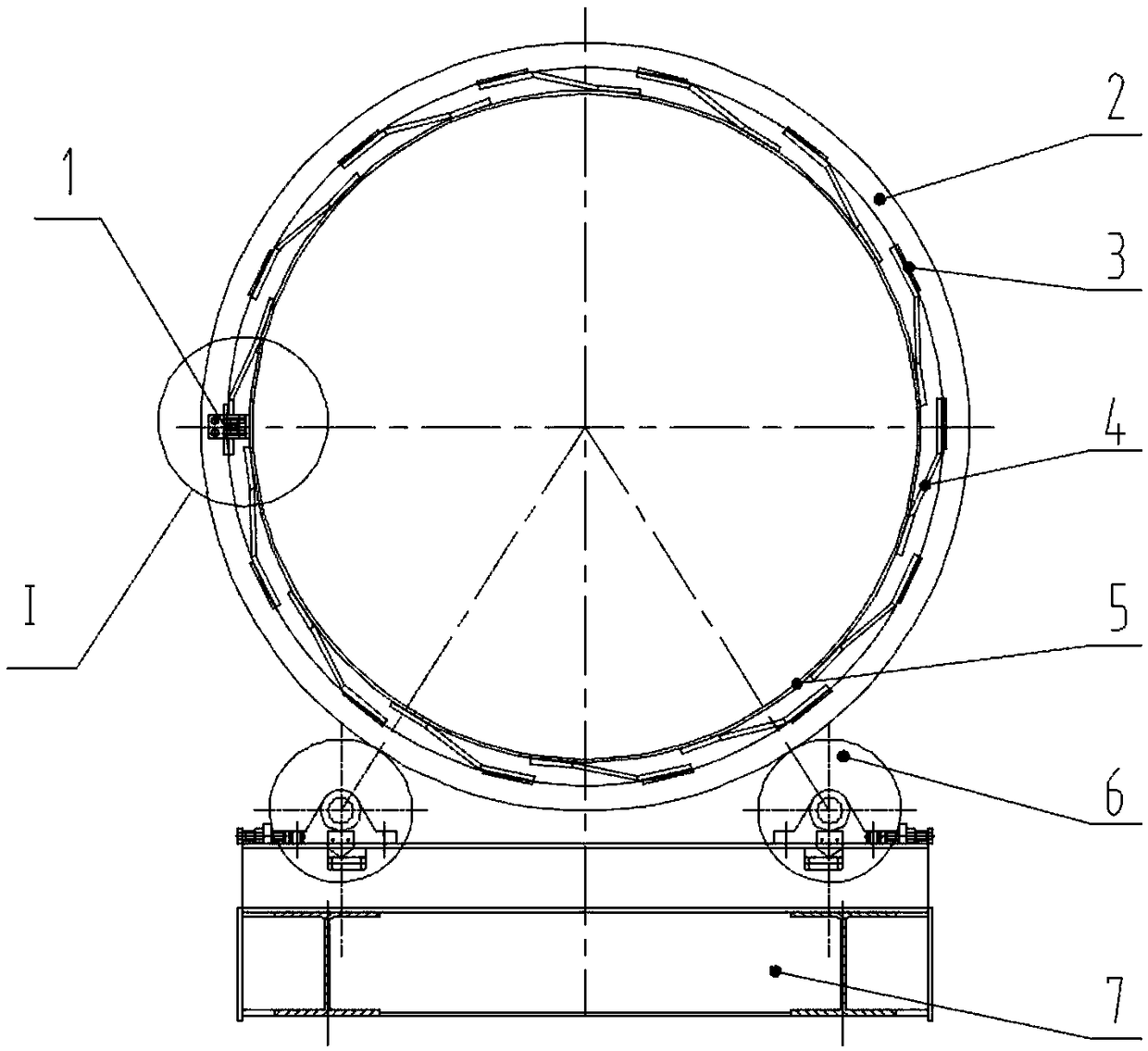

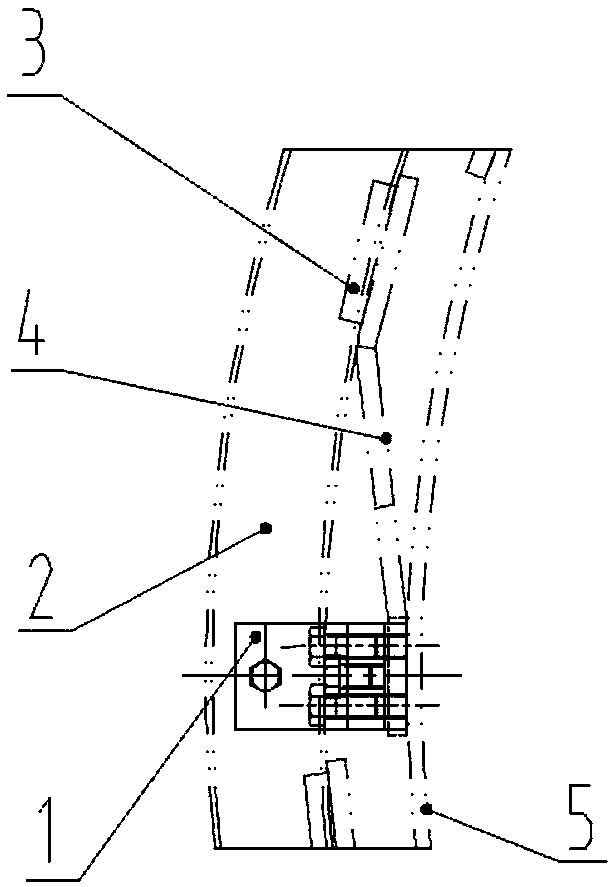

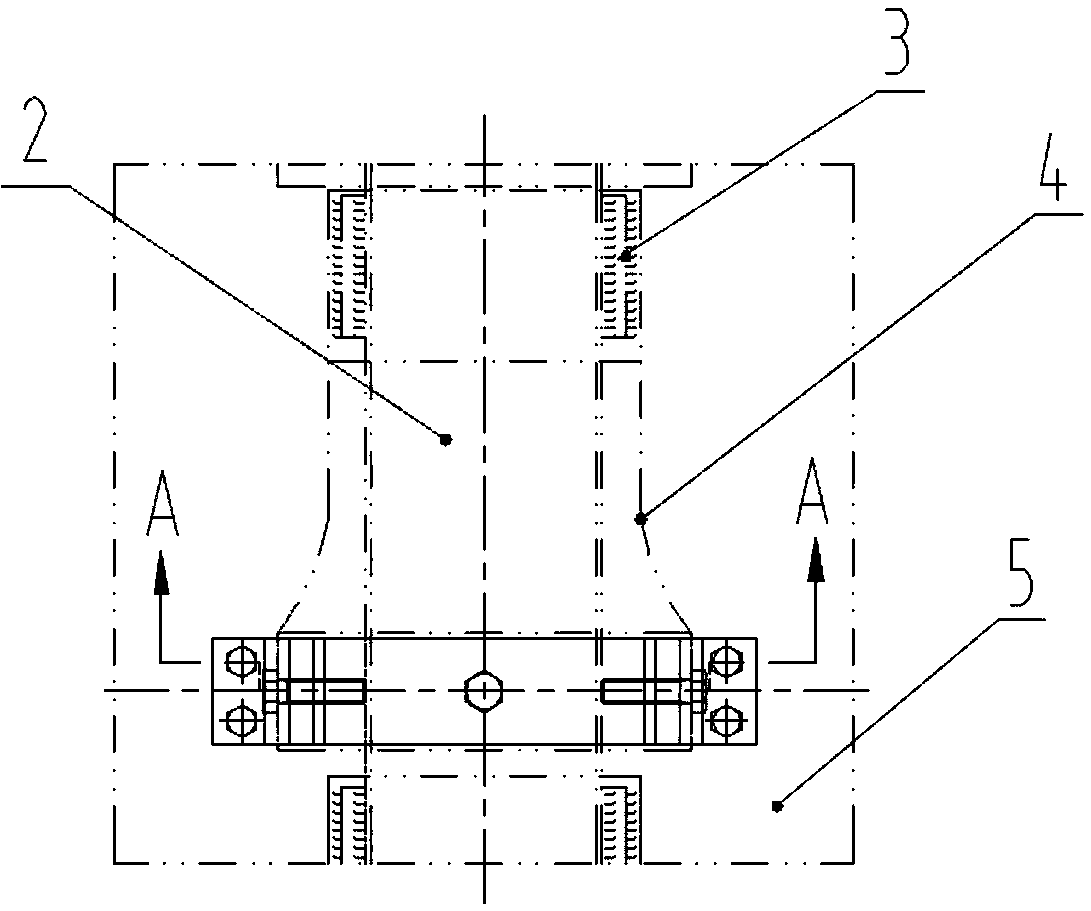

[0041] see Figure 1 to Figure 3 , shows the welding tooling for the support ring of the spring plate type drying cylinder of the asphalt mixture mixing equipment of the present invention.

[0042] The asphalt mixture mixing equipment spring plate type drying drum support ring welding tool includes a support ring positioning device 1, a support roller 6 and a chassis 7, and support rollers 6 are arranged on both sides of the upper surface of the chassis 7, and the support ring positioning device 1 is installed between the support ring 2 and the drum 5, and a plurality of stoppers 3 and spring plates 4 are arranged between the support ring 2 and the drum 5, wherein the support ring positioning device 1 includes a support 1-1, Bottom plate 1-2, backing plate 1-3, fixing bolts 1-4, radial adjustment bolts 1-5 and axial adjustment bolts 1-6, one end of the bottom plate 1-2 protrudes downward and can be spot welded It is fixed with the drum 5, and a backing plate 1-3 is provided bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com