Leveling anti-slip device for car elevator

A technology for elevators and cars, applied in the field of leveling anti-slip devices, can solve the problems of elevator safety impact, reduced passenger safety, reduced braking force, etc., so as to improve braking efficiency, improve safety, and prolong service time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

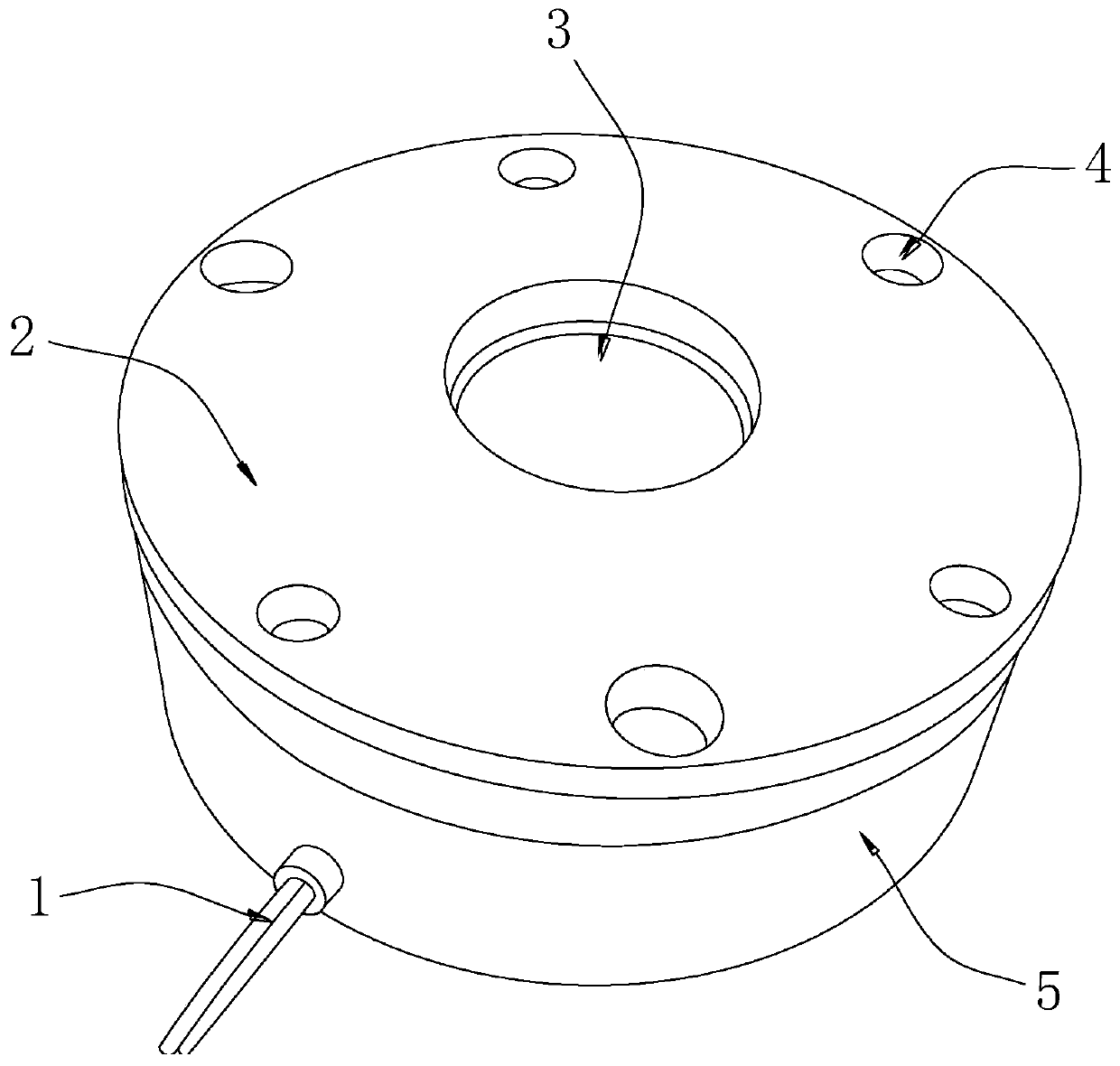

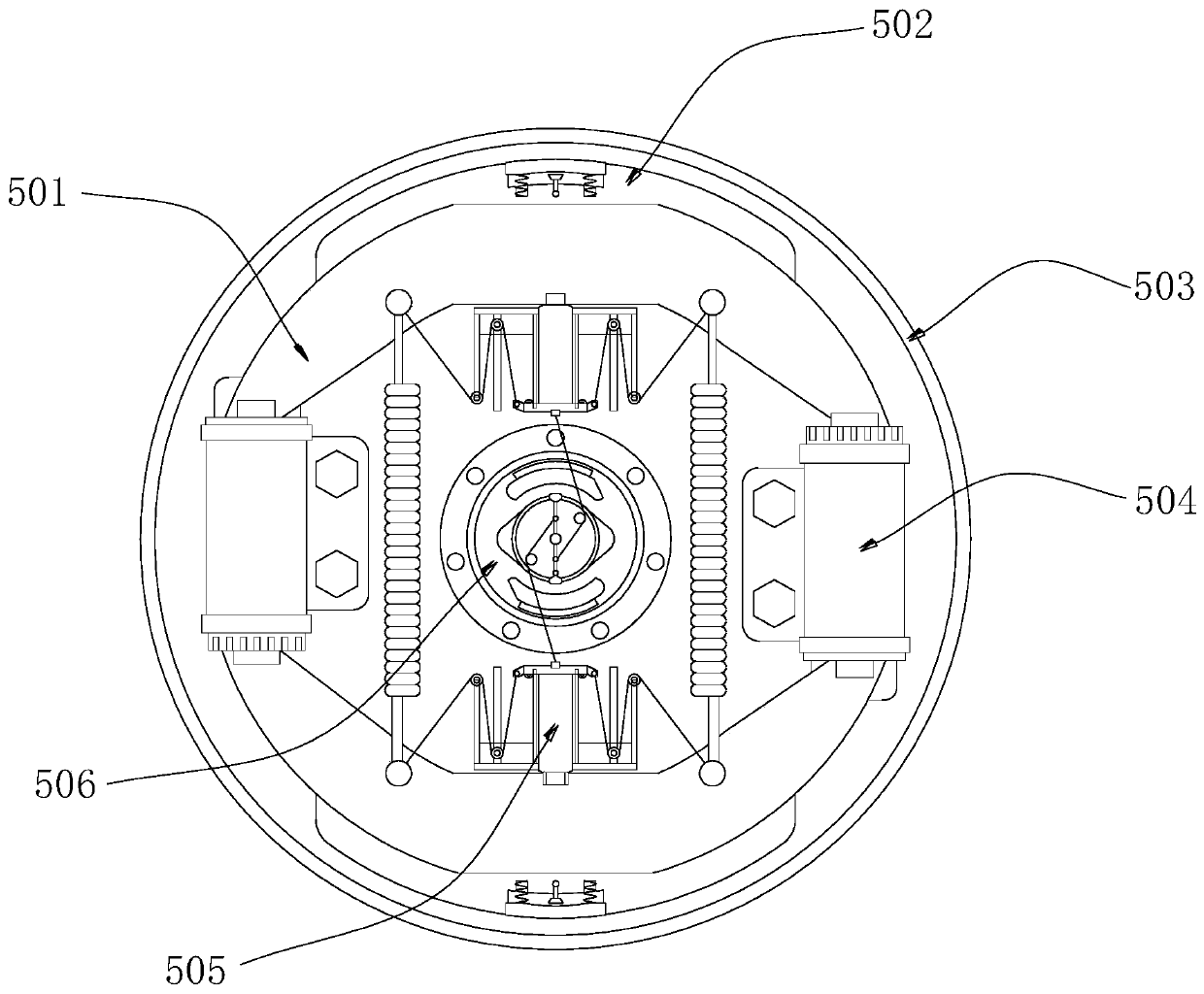

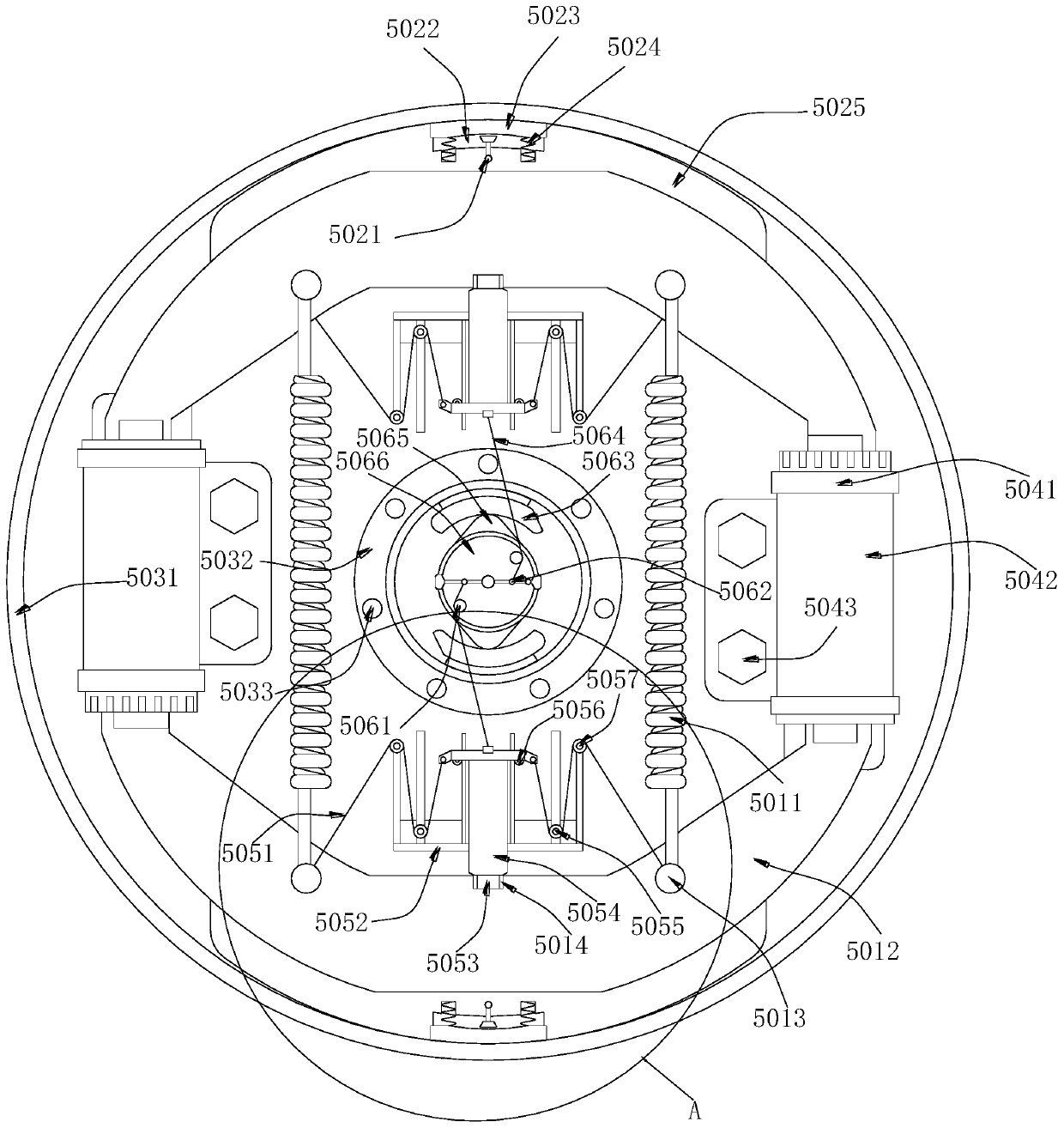

[0021] see Figure 1-Figure 4, the present invention provides a leveling anti-slip device for a car elevator, the structure of which includes a power cord 1, a traction sheave transmission disc 2, a first drive shaft 3, an assembly hole 4, and a brake wheel 5, the traction sheave transmission The disc 2 has a circular structure, and is mounted on the upper end of the brake wheel 5 by snap-fitting. The side of the brake wheel 5 is provided with a power cord 1, and the first drive shaft 3 is of a circular structure, and is installed by embedding In the middle of the traction wheel transmission disc 2, the assembly holes 4 are provided with more than two, and are evenly and equidistantly distributed on the surface of the traction wheel transmission disc 2. The brake wheel 5 includes a main braking device 501, a friction device 502 , a transmission main body 503, a driving mechanism 504, a limit mechanism 505, and an auxiliary device 506. The main braking device 501 is located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com