A thermal insulation device for on-line coated glass production

A technology of heat preservation device and coated glass, applied in the field of machinery, can solve the problems of inconvenient protection frame shock absorption and buffering, inconvenient protection frame locking and buffering function, and lack of protective function of movable door, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

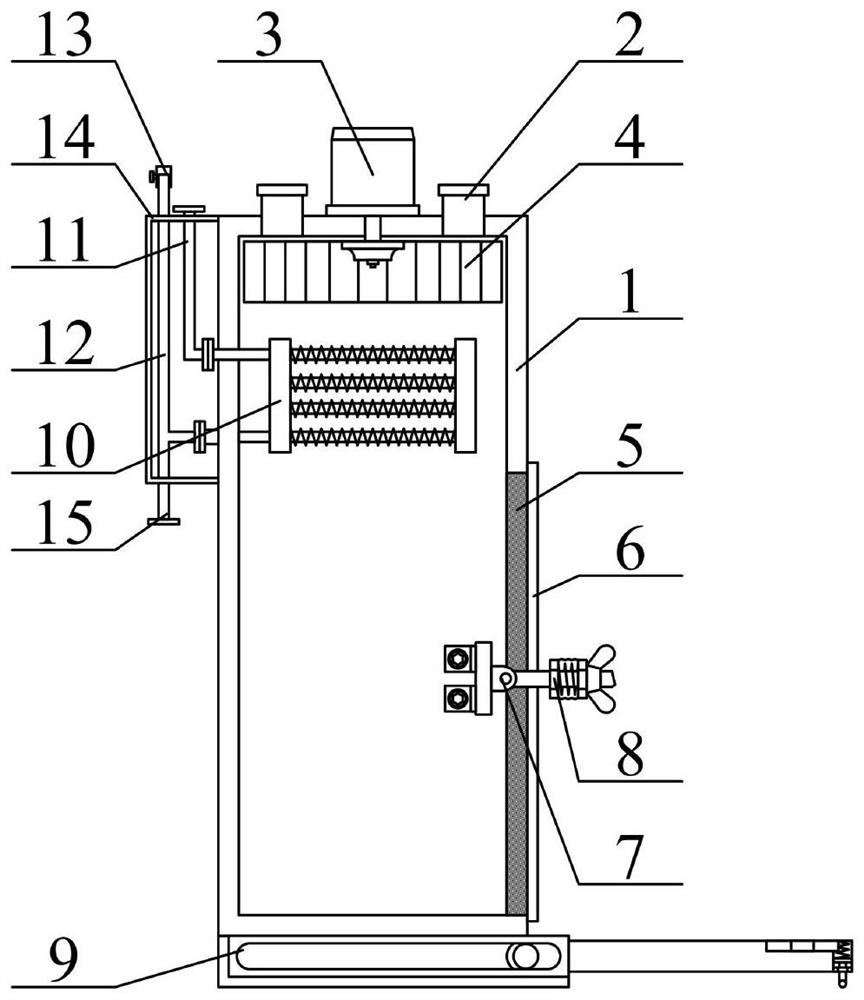

[0039] as attached figure 1 And attached Figure 4 shown

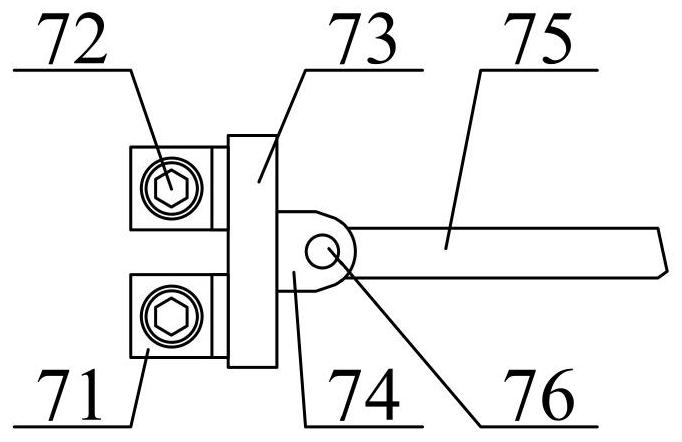

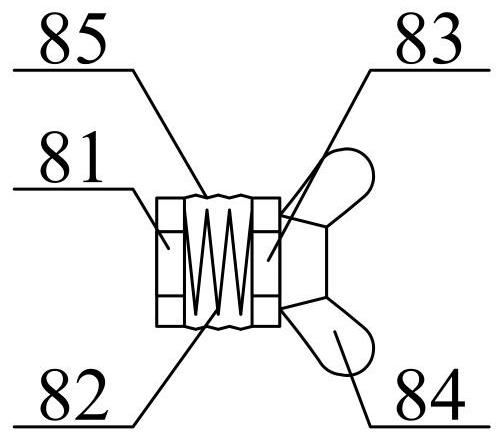

[0040]The invention provides a thermal insulation device for online coated glass production, which includes a device housing 1, an air outlet pipe 2, a motor 3, fan blades 4, high-temperature silicate fiber cotton 5, a movable door 6, a movable mounting frame structure 7, a lock Tight buffer fixed frame structure 8, which can be socketed with protective carrier structure 9, steam radiator 10, inlet pipe 11, connecting pipe 12, steam pressure control valve 13, protective cover 14 and steam control circuit 15, the air outlet pipe 2. Inserted on the left and right sides of the upper part of the device casing 1; the motor 3 bolts are installed on the middle and upper part of the device casing 1, and the output shaft of the motor 3 runs through the top of the device casing 1; the fan blade 4 is arranged on the device The inner side of the casing 1, while the fan blade 4 bolts are installed on the output shaft of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com