Ultra-low-carbon bake hardening steel sheet and production method thereof

A technology of bake hardening and production method, applied in the metallurgical field, can solve the problems of increased cost and fluctuation of the bake hardening value of the finished product, and achieves the effects of good comprehensive performance, stable bake hardening value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

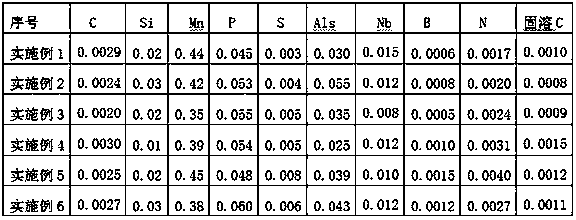

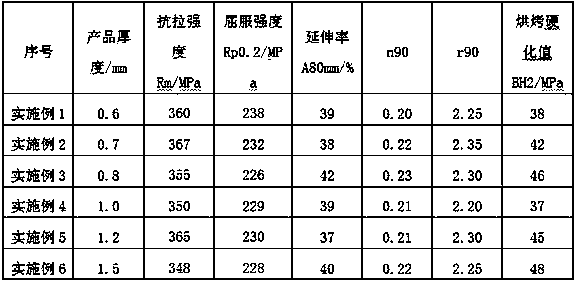

[0022] The thickness of the ultra-low-carbon bake-hardened steel plate in this embodiment is 0.6 mm, and its chemical composition and mass percentage are shown in Table 1.

[0023] The production method of the ultra-low-carbon bake-hardened steel plate in this embodiment includes steelmaking, continuous casting, slab heating, hot rolling, laminar cooling, acid rolling, continuous annealing, and smoothing processes. The specific process steps are as follows:

[0024] (1) Steelmaking process: see Table 1 for the chemical composition and mass percentage of the tapping molten steel; then continuously cast into slabs;

[0025] (2) Slab heating process: divided into the first heating section, the second heating section, the third heating section and the soaking section, the slab is in the furnace for 135 minutes, the temperature of the third heating section is 1230°C, and the temperature of the soaking section is 1210°C;

[0026] (3) Hot rolling process: rough rolling is reciprocati...

Embodiment 2

[0033] The thickness of the ultra-low-carbon bake-hardened steel plate in this embodiment is 0.7mm, and its chemical composition and mass percentage are shown in Table 1.

[0034] The production method of the ultra-low-carbon bake-hardened steel plate in this embodiment includes steelmaking, continuous casting, slab heating, hot rolling, laminar cooling, acid rolling, continuous annealing, and smoothing processes. The specific process steps are as follows:

[0035] (1) Steelmaking process: see Table 1 for the chemical composition and mass percentage of the tapping molten steel; then continuously cast into slabs;

[0036] (2) Slab heating process: It is divided into the first heating section, the second heating section, the third heating section and the soaking section. The time for the slab in the furnace is 130 minutes, the temperature of the third heating section is 1180°C, and the temperature of the soaking section is 1150°C;

[0037] (3) Hot rolling process: rough rolling ...

Embodiment 3

[0044] The thickness of the ultra-low-carbon bake-hardened steel plate in this embodiment is 0.8mm, and its chemical composition and mass percentage are shown in Table 1.

[0045] The production method of the ultra-low-carbon bake-hardened steel plate in this embodiment includes steelmaking, continuous casting, slab heating, hot rolling, laminar cooling, acid rolling, continuous annealing, and smoothing processes. The specific process steps are as follows:

[0046] (1) Steelmaking process: see Table 1 for the chemical composition and mass percentage of the tapping molten steel; then continuously cast into slabs;

[0047] (2) Slab heating process: divided into the first heating section, the second heating section, the third heating section and the soaking section, the slab is in the furnace for 120 minutes, the temperature of the third heating section is 1250°C, and the temperature of the soaking section is 1220°C;

[0048] (3) Hot rolling process: rough rolling is reciprocatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com