Bamboo-sourced cellulose acetate and preparation method thereof

A cellulose acetate and cellulose technology, applied in the field of agricultural and forestry biological resources utilization, can solve the problems of difficult industrial application, great harm to the human body and the environment, and corrosion of metals, so as to improve the utilization value and ways, and the process is stable and controllable, Apply promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

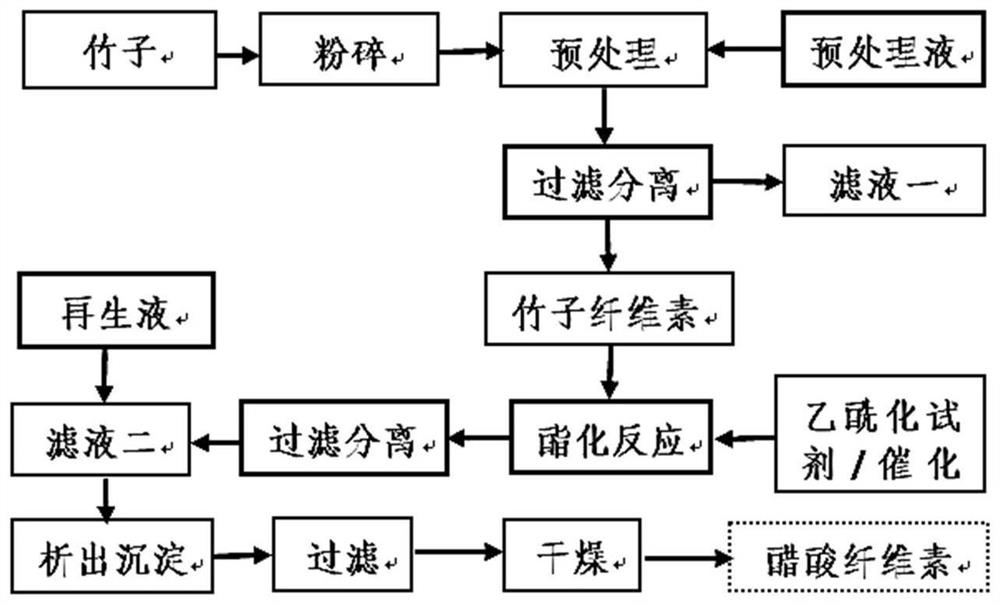

Method used

Image

Examples

Embodiment 1

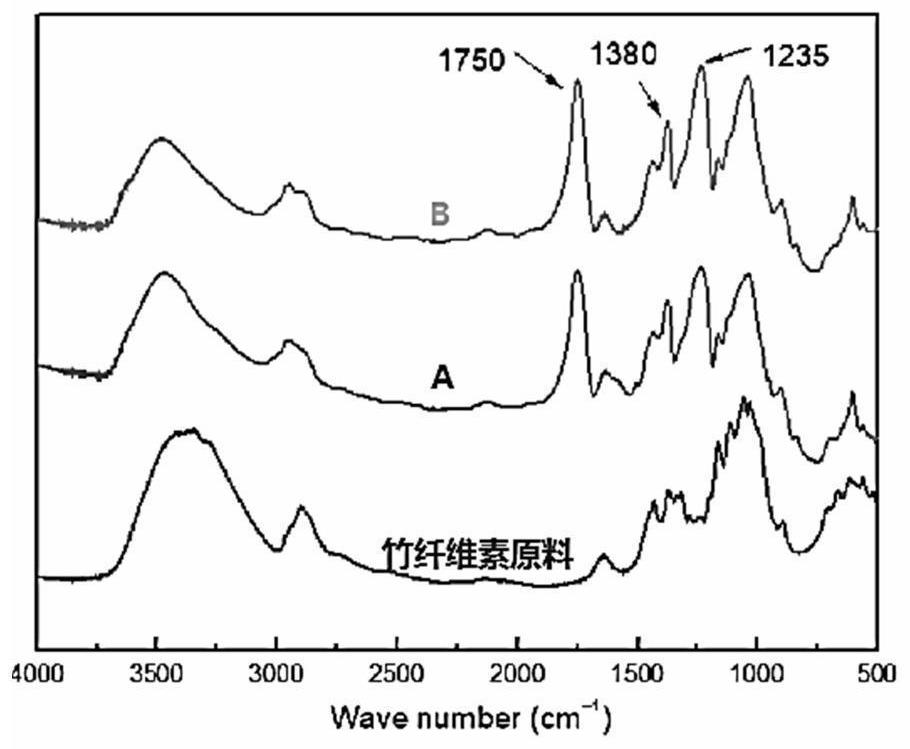

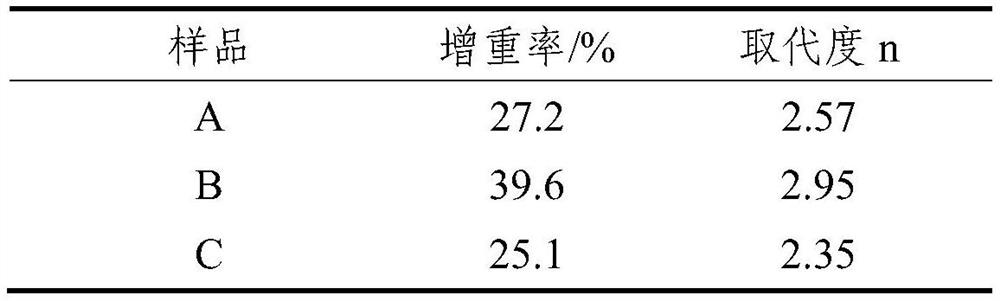

[0037] Embodiment 1 The acetylation reaction of chemical pretreatment bamboo substrate

[0038] The present embodiment provides a preparation method of bamboo-derived cellulose acetate, specifically:

[0039] 0.5 g of the substrate obtained after the pulverized bamboo is chemically pretreated with γ-valerolactone is dispersed in a round-bottomed flask containing 5 mL of dimethyl sulfoxide, and 2 mL of 200 g / L NaOH solution is added for activation for 30 min; then the flask is After being transferred to a water bath and heated in a water bath at 80° C. for 15 min, 10 mL of vinyl acetate and 0.1 mL of catalyst N,N-diisopropylethylamine were immediately added and the reaction was carried out for 5 min. After the end, the solid-liquid of the reaction mixture was centrifuged, and 50 mL of anhydrous ethanol was added to the separated supernatant to precipitate a white precipitate; the precipitated product was separated by filtration, and the solid filter residue was fully washed and...

Embodiment 2

[0040] The acetylation reaction of the bamboo cellulose of embodiment 2 separation and purification

[0041] The present embodiment provides a preparation method of bamboo-derived cellulose acetate. The difference between the specific steps and Example 1 is that the bamboo raw material is the bamboo cellulose obtained by purification after removing lignin and hemicellulose, and obtaining cellulose acetate B .

Embodiment 3

[0042] Embodiment 3 bamboo powder is directly the cellulose acetylation reaction of raw material

[0043] The present embodiment provides a preparation method of bamboo-derived cellulose acetate. The difference between the specific steps and Example 1 is only that the bamboo raw material is bamboo powder without any pretreatment to obtain cellulose acetate C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com