A kind of preparation method and application of gradient structure pet melt-blown non-woven fabric for secondary forming filter of double rolling mill

A technology of melt-blown non-woven fabric and gradient structure, which is applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc. It can solve the problems of reducing the dirt-holding capacity of materials, reducing the tearing strength of materials, and reducing the filtration accuracy of materials. Ensures filtration efficiency, improves water/air pressure resistance, and has a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

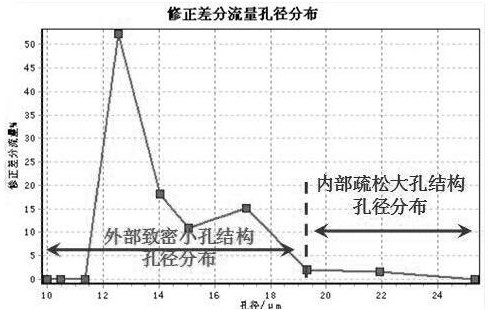

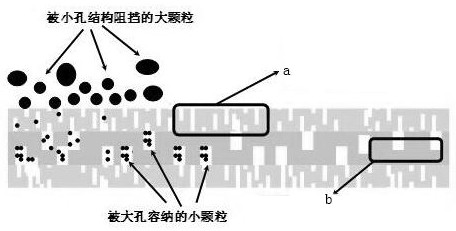

[0039] According to the preparation steps of the above preparation method, firstly, PET chips with a viscosity of 0.45dl / g and a melting point of 265°C are pre-crystallized at 120°C for 30 minutes and fully dried at 160°C for 8 hours to obtain PET meltblown fibers by melt blown method , and then use hot air at 0.2MPa and 340°C for drafting to obtain PET melt-blown fiber web; pass the fiber web through a 130°C, 70N primary flat roll mill and a 220°C, 20N secondary flat roll mill to obtain PET melt-blown non-woven fabric. The fiber fineness of PET melt-blown non-woven fabric is 0.25D, and the weight range is 50g / m 2 , the thickness is 0.4mm. The thickness of the internal loose macroporous structure of PET meltblown non-woven fabric is 0.24mm, the pore diameter ranges from 20μm to 25μm, and the thickness of the external dense small pore structure is 0.08mm, and the pore diameter ranges from 3μm to 5μm.

Embodiment 2

[0043] PET chips with a viscosity of 0.45dl / g and a melting point of 265°C are pre-crystallized and fully dried to obtain a PET melt-blown fiber web, and the fiber web is passed through a 140°C, 80N primary flat roll mill and a 220°C, 30N The second flat roll mill obtains PET melt-blown nonwovens with gradient structure. The fiber fineness of PET melt-blown non-woven fabric is 0.25D, and the weight range is 70g / m 2 , the thickness is 0.45mm. The pore diameter range of the internal loose macroporous structure of PET melt-blown non-woven fabric is 17 μm to 20 μm, and the pore diameter range of the external dense small pore structure is 3 μm to 5 μm.

Embodiment 3

[0047]PET chips with a viscosity of 0.4dl / g and a melting point of 265°C are pre-crystallized and fully dried to obtain a PET melt-blown fiber web, and the fiber web is passed through a 140°C, 85N primary flat roll mill and a 230°C, 40N The second flat roll mill obtains PET melt-blown nonwovens with gradient structure. The fiber fineness of PET melt-blown non-woven fabric is 0.35D, and the weight range is 90g / m 2 , the thickness is 0.5mm. The thickness of the internal loose macroporous structure of PET meltblown non-woven fabric is 0.3mm, the pore diameter ranges from 20μm to 25μm, and the thickness of the external dense small pore structure is 0.1mm, and the pore diameter ranges from 5μm to 7μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com