Novel rotating shaft structure of swinging rocket engine

A rocket engine and shaft structure technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as the inability to use swingable engines, and achieve thermal control implementation problems, high fit, and beautiful appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments.

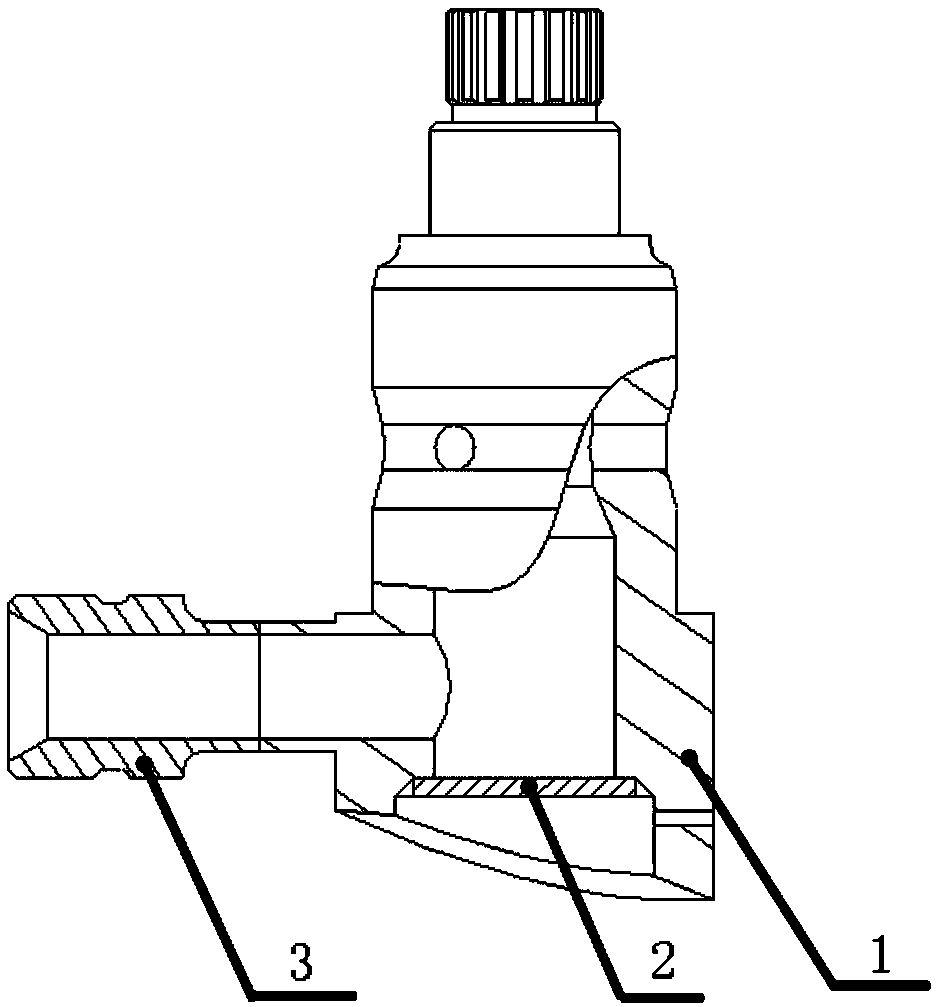

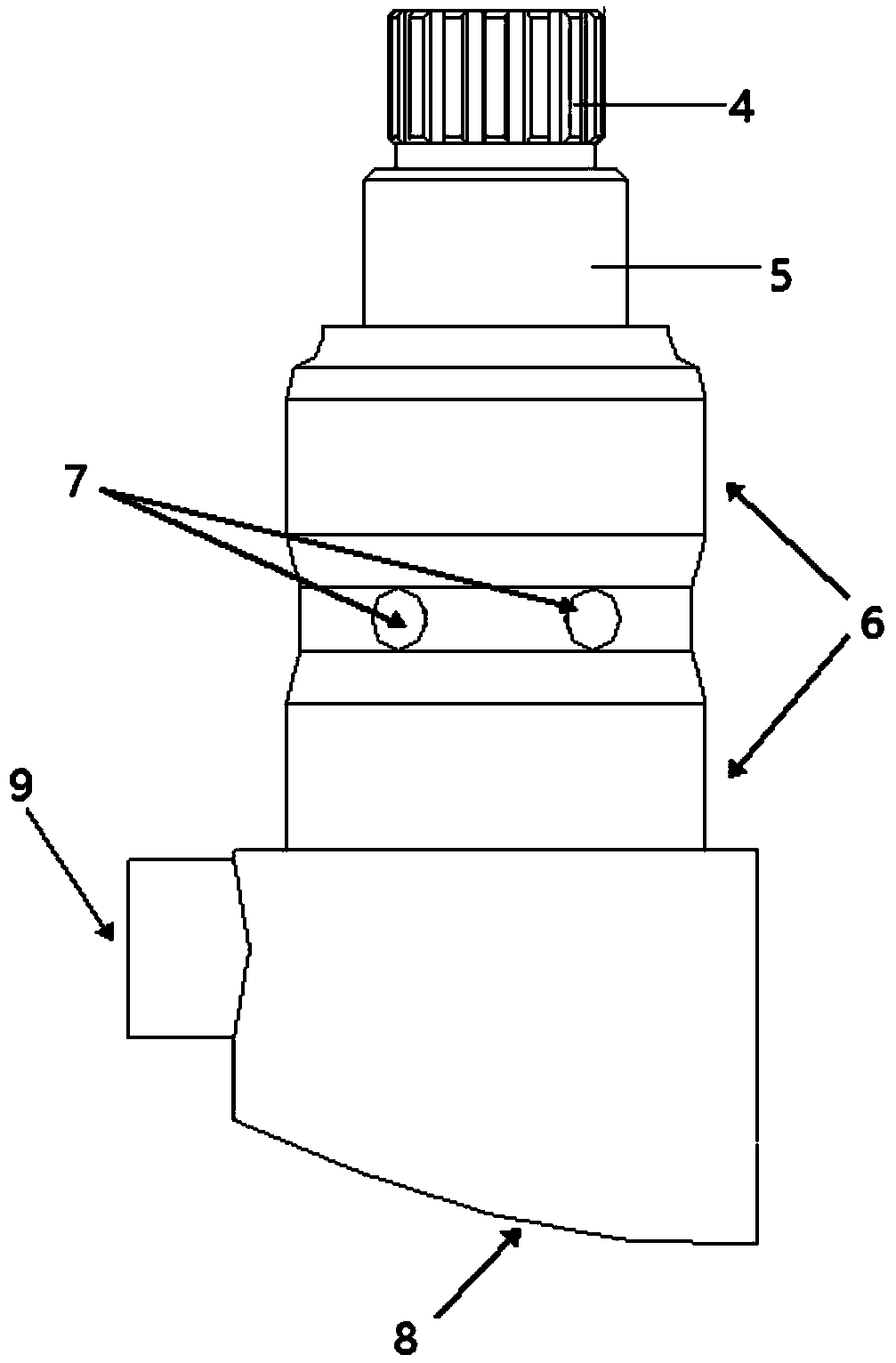

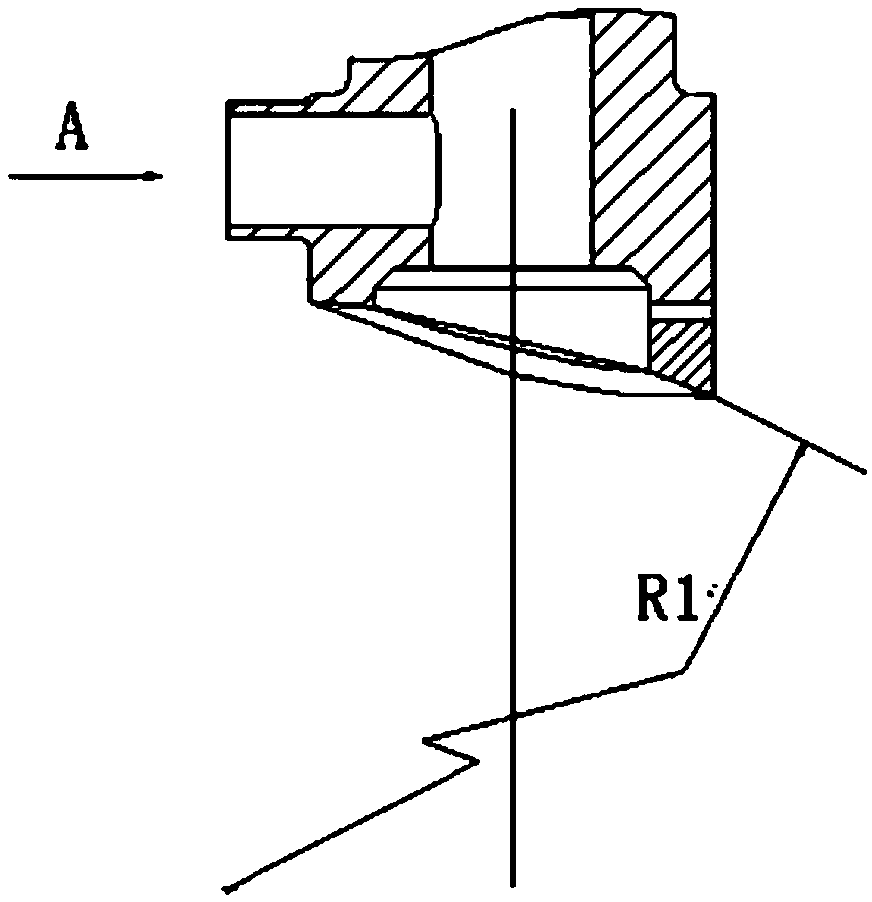

[0022] The embodiment of the present invention provides a novel rotating shaft structure of a rockable rocket motor, see Figure 1-Figure 2 , comprising a rotating shaft 1, a shaft cover plate 2 and a shaft nozzle 3, the lower end of the rotating shaft 1 is welded with the shaft cover plate 2 to form a propellant liquid collecting chamber inside the rotating shaft; the upper end of the rotating shaft 1 is provided with a key interface 4 for connecting For the torque-providing motor, a bearing interface 5 is arranged under the upper key interface, and two sections of sealing surfaces 6 are arranged under the bearing interface, and the two sections of sealing surfaces are connected with the dynamic sealing structure, and several propellant inlets 7 are arranged between the two sections of sealing surfaces; The rotating shaft 1 is welded with the shaft nozzle 3, and the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com