Novel faucet opening and closing handle

A switch handle and faucet technology, applied in valve details, engine components, valve operation/release devices, etc., can solve the problems of high plating defect rate, unsightly, and the switch handle is not widely used, to increase the surface texture, Beautiful appearance, good-looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

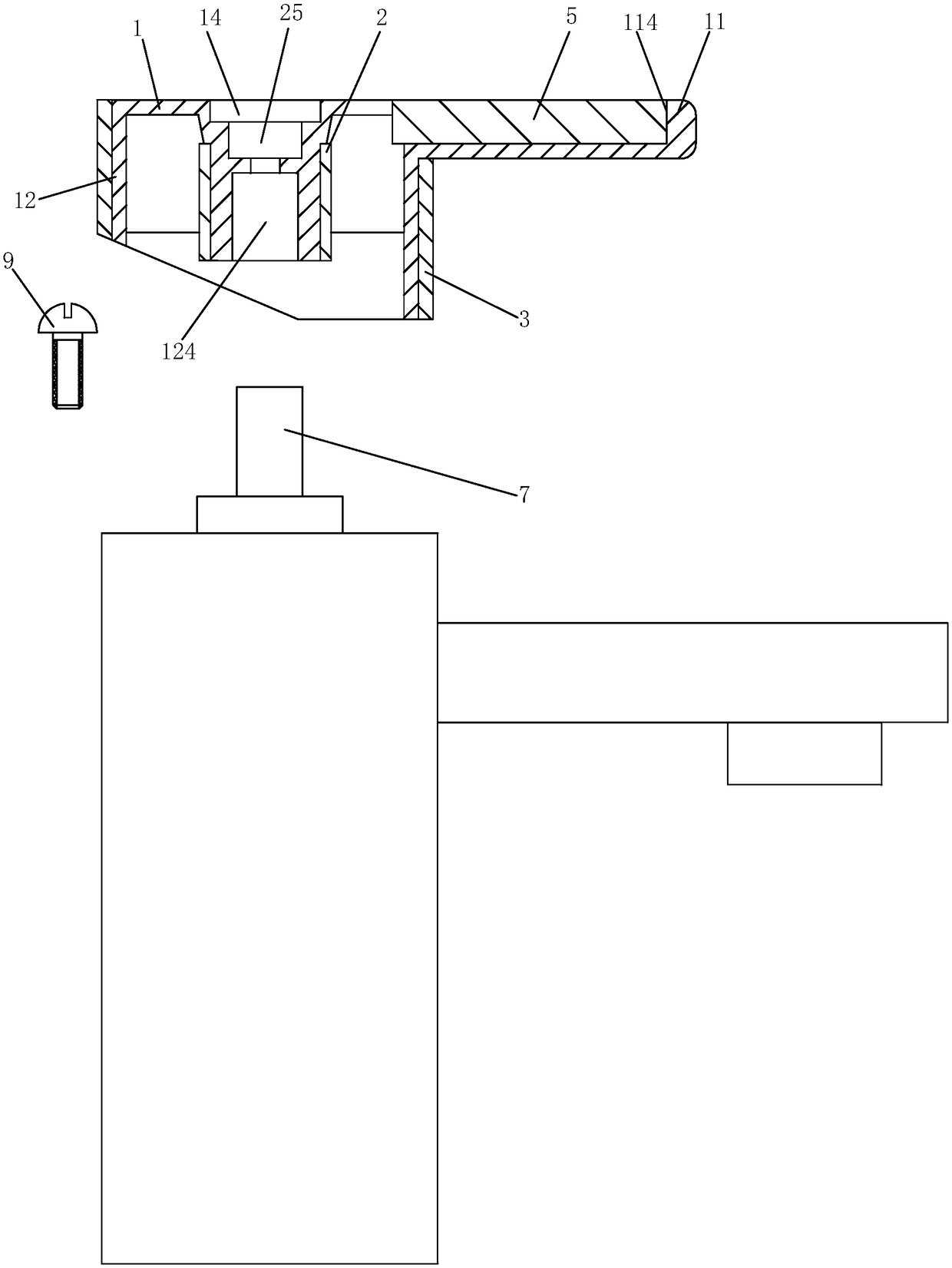

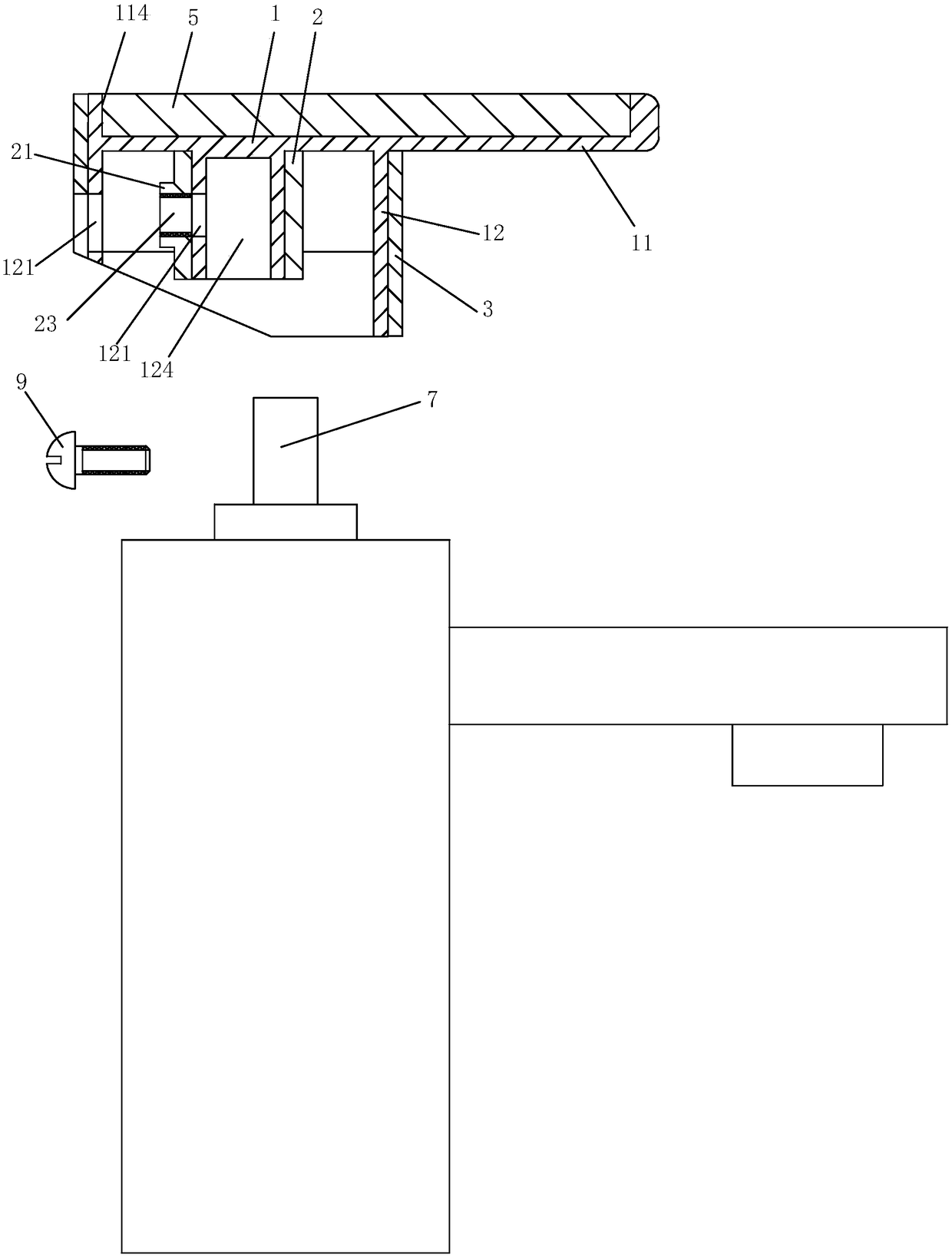

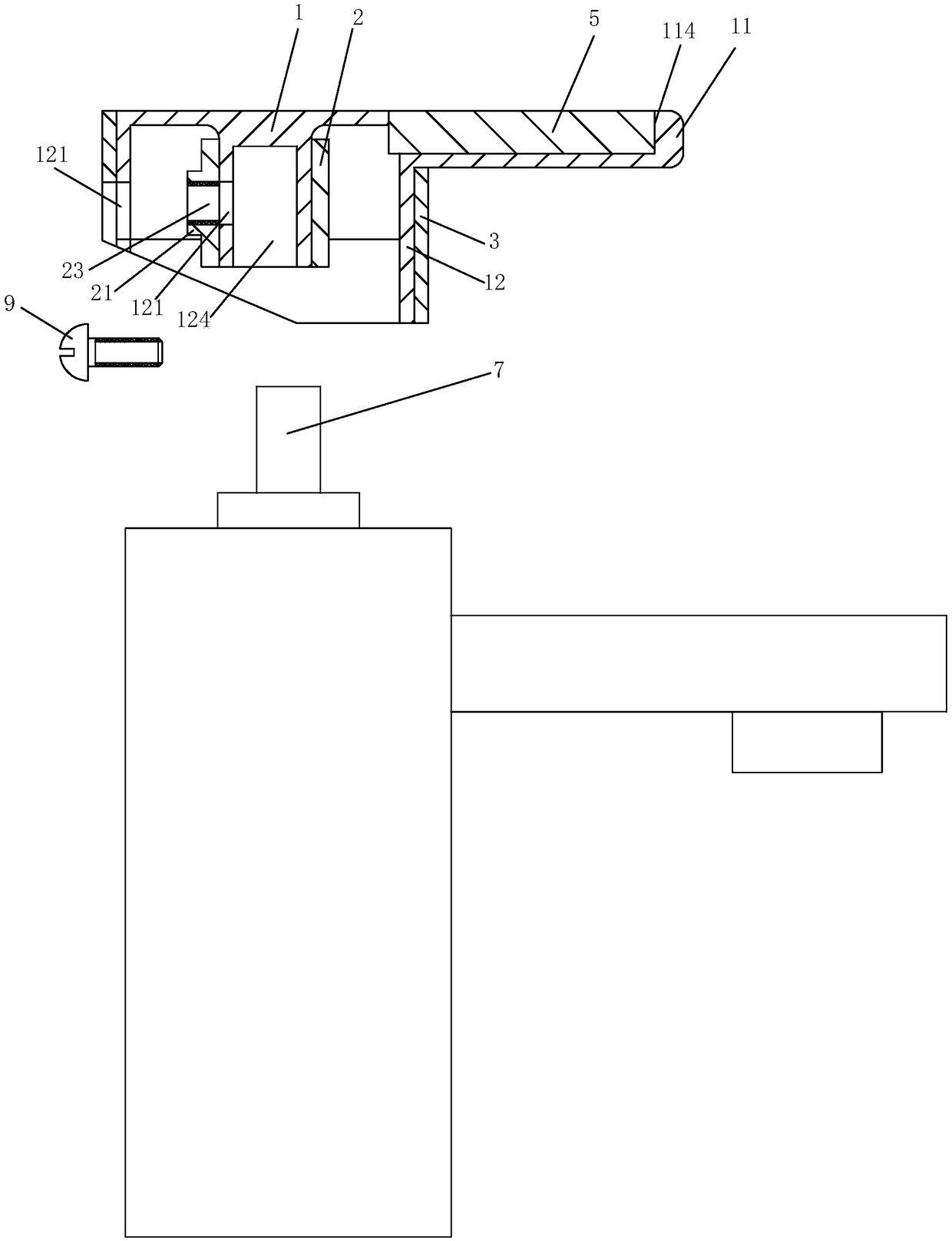

[0019] refer to figure 1 As shown, a new faucet switch handle provided by the first embodiment of the present invention includes a plastic part 1, wherein the plastic part 1 includes a long plastic handle 11 and a plastic cylinder located at one end of the long plastic handle 11 and extending downwards. body 12, the plastic cylinder 12 is provided with a valve core rod mounting hole 124, the valve core rod mounting hole 124 is nested with a metal inner sleeve 2, the outer surface of the plastic cylinder 12 is provided with a metal decorative sleeve 3, and the top of the plastic long handle 11 is provided There is a groove 114, and the metal block 5 is embedded in the groove 114.

[0020] In the embodiment of the present invention, the metal inner sleeve 2 is nested outside the installation hole 124 of the spool rod to improve the strength and increase the burst-proof strength of the faucet switch handle to make it more durable. Metal decoration is provided on the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com