Packaging structure and method for flexible liquid crystal display panels

A flexible liquid crystal display, packaging structure technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of cost waste, low yield, and inadequate sealing, and achieve the effect of improving performance and yield, and saving manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

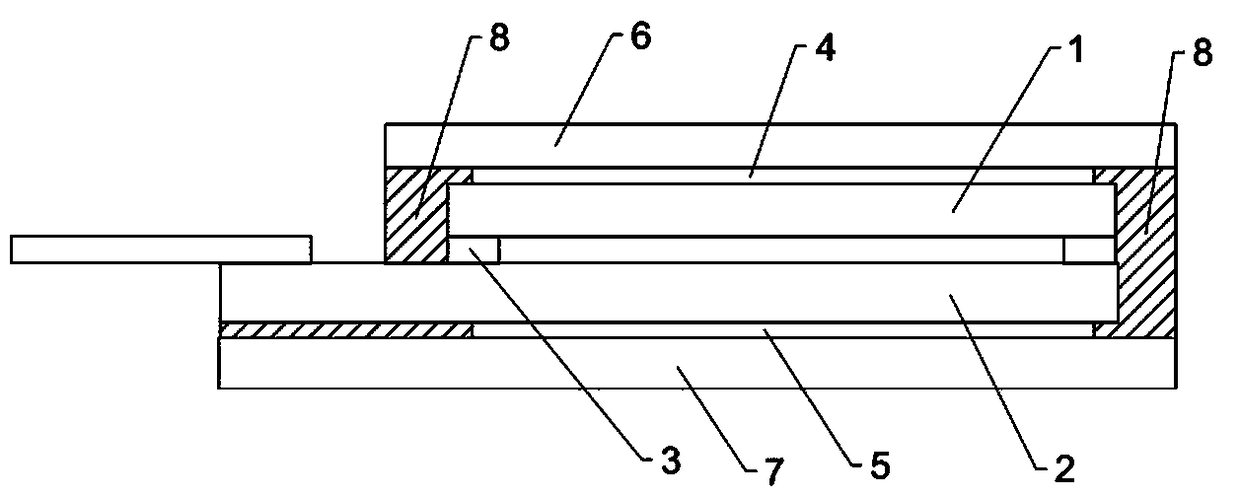

[0032] A packaging structure for a flexible liquid crystal display panel, comprising:

[0033] a first substrate having a first inner surface and a first outer surface;

[0034] a second substrate disposed opposite to the first substrate, wherein the second substrate has a second inner surface and a second outer surface, and the second inner surface faces the first inner surface of the first substrate;

[0035] A sealant, located between the first substrate and the second substrate, for bonding the first substrate and the second substrate;

[0036] a sealant, which is located between the first substrate and the second substrate and on the outside of the sealant;

[0037] a first polarizer disposed on one side of the first outer surface of the first substrate;

[0038] a second polarizer disposed on one side of the second outer surface of the second substrate;

[0039] Both the first polarizer and the second polarizer are polarizers with low water vapor transmission rate.

...

Embodiment 2

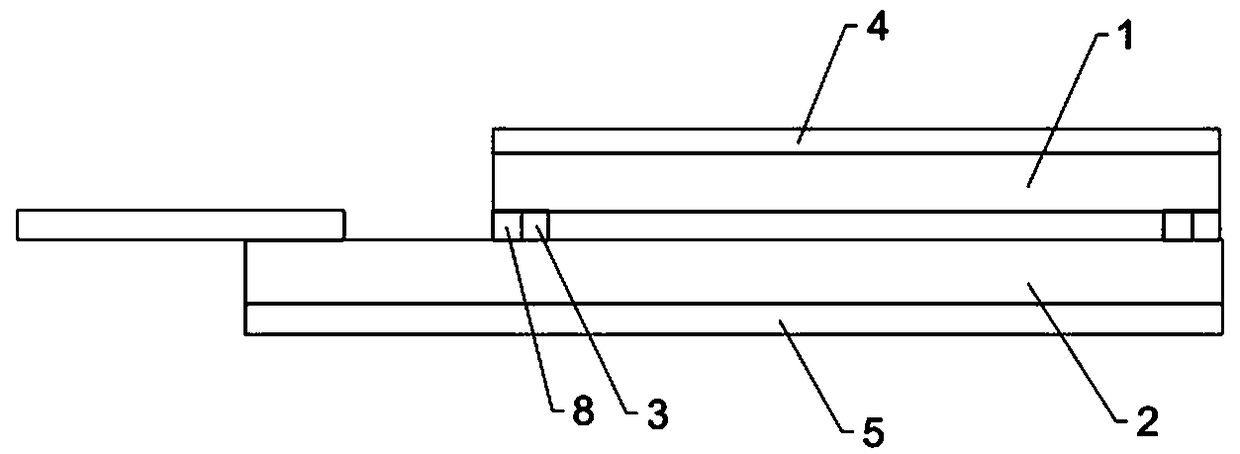

[0054] A packaging method for a flexible liquid crystal display panel, comprising the following steps:

[0055] S1. Provide a first substrate and a second substrate, coat a circle of sealant on the first substrate or the second substrate, and coat a circle of sealant around the periphery of the sealant;

[0056] S2. Carrying out box alignment of the first substrate and the second substrate;

[0057] S3. Curing the frame sealant and the sealant;

[0058] S4. Attaching a first polarizer and a second polarizer on the sides of the first substrate and the second substrate that are far away from each other, both of the first polarizer and the second polarizer have a low water vapor transmission rate polarizers.

[0059] In the present invention, the sealing glue is epoxy glue, but not limited thereto.

[0060] In the present invention, the sealant is a moisture-proof material, preferably, the sealant is formed after curing of UV glue that can block water vapor.

[0061] In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com