Flexible touch panel and intelligent terminal

A flexible touch and panel technology, applied in the fields of instruments, electrical digital data processing, static electricity, etc., can solve problems such as defective products, burnt substrates, static electricity accumulation, etc., to prevent ESD phenomenon and improve the yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

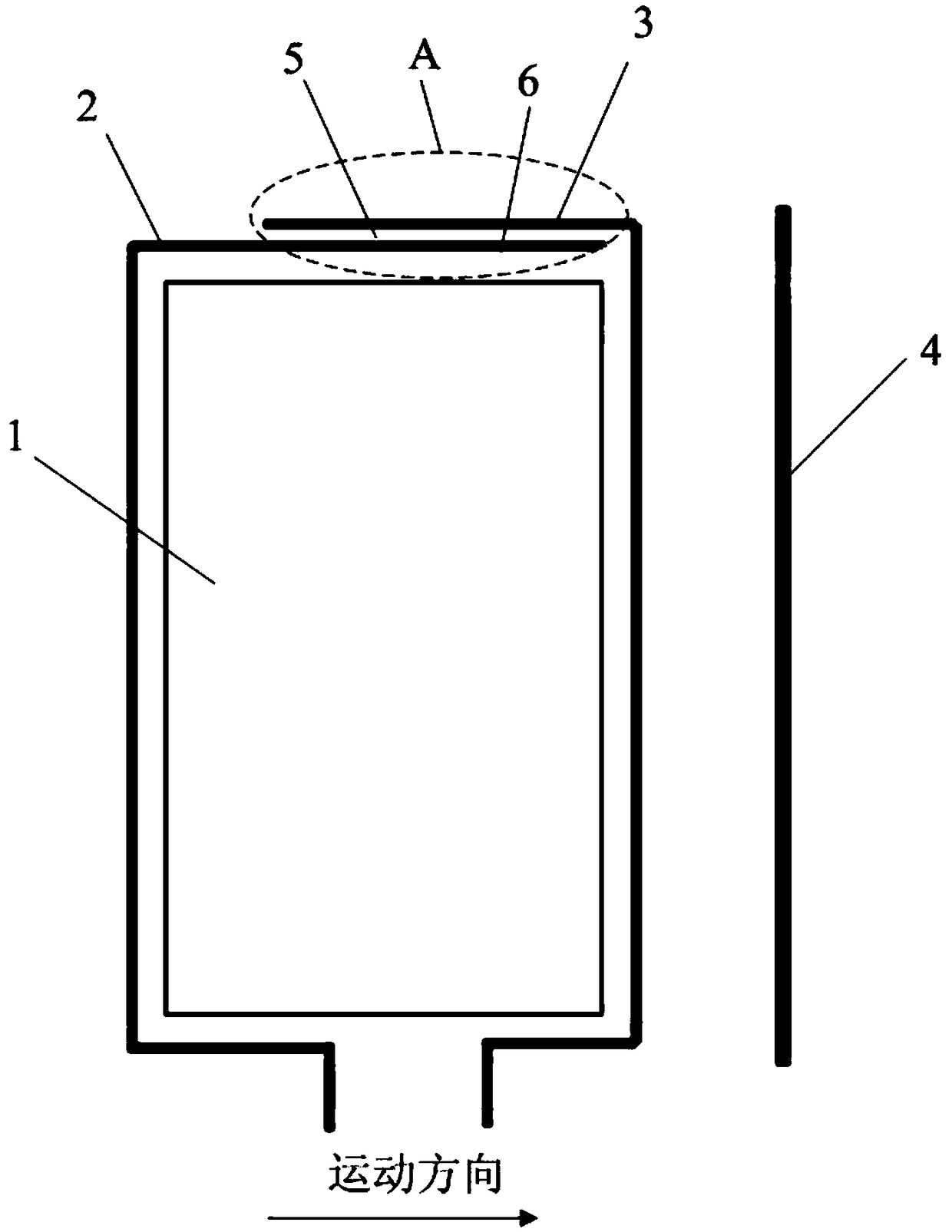

[0027] figure 2 It is a schematic structural diagram of a flexible touch panel provided by Embodiment 1 of the present invention. Embodiment 1 of the present invention provides a flexible touch panel, including a body 1 and a grounding wire arranged around the body 1. The body 1 is made of a flexible material. In the embodiment, the material of the body 1 is polyethylene terephthalate (PET). A first fracture 5 is provided on the ground wire, and the first fracture 5 divides the ground wire into a first ground wire 2 and a second ground wire 3 . The first ground wire 2 and the second ground wire 3 are parallel to each other in the overlapping area A at the first fracture 5 . An antistatic portion 6 is provided on the first ground wire 2 or the second ground wire 3 in the overlapping area A at the first cutout 5 .

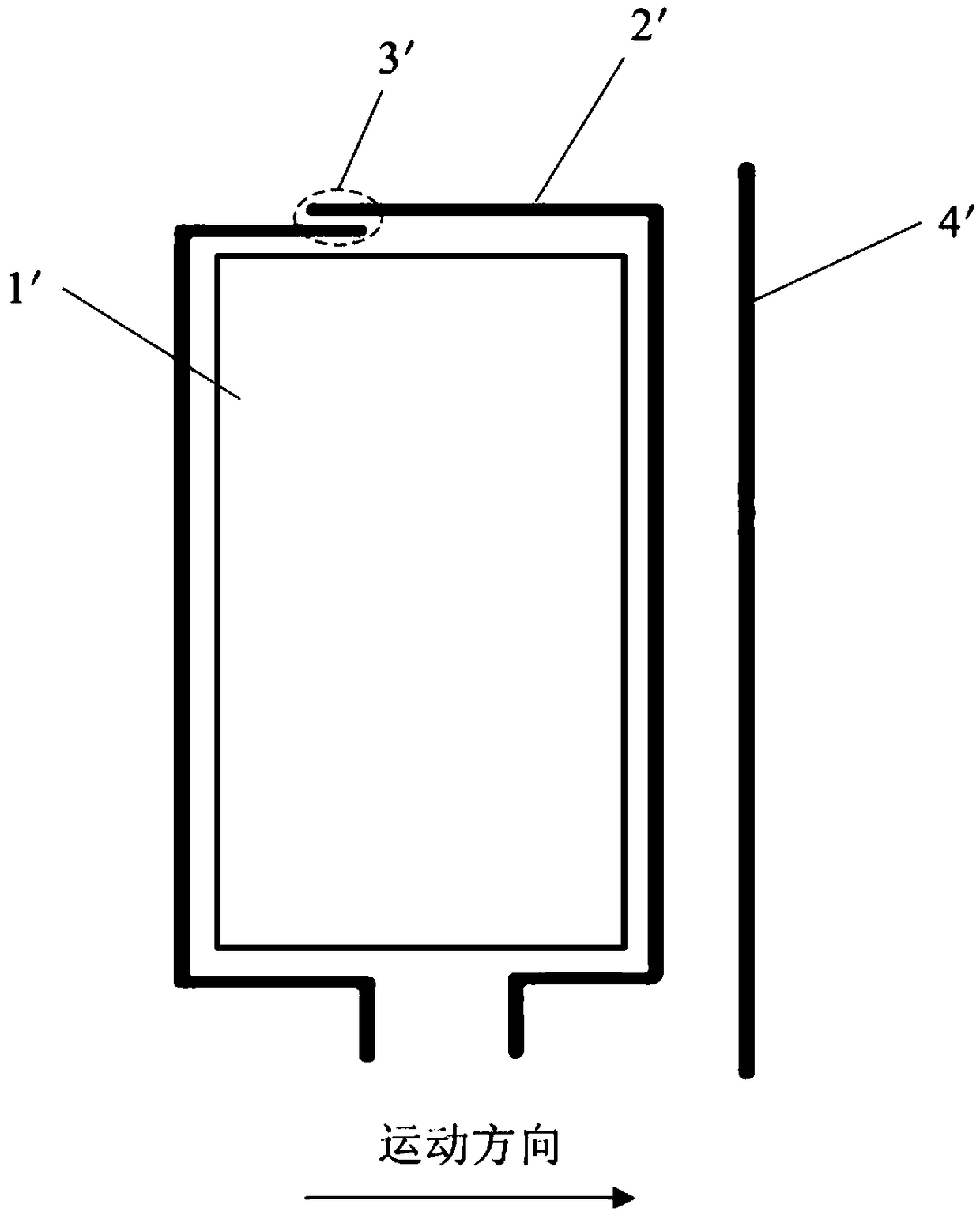

[0028] The body in the prior art is a rigid body. With the upgrading of products, the body is developing towards flexibility. During the development process, elec...

Embodiment 2

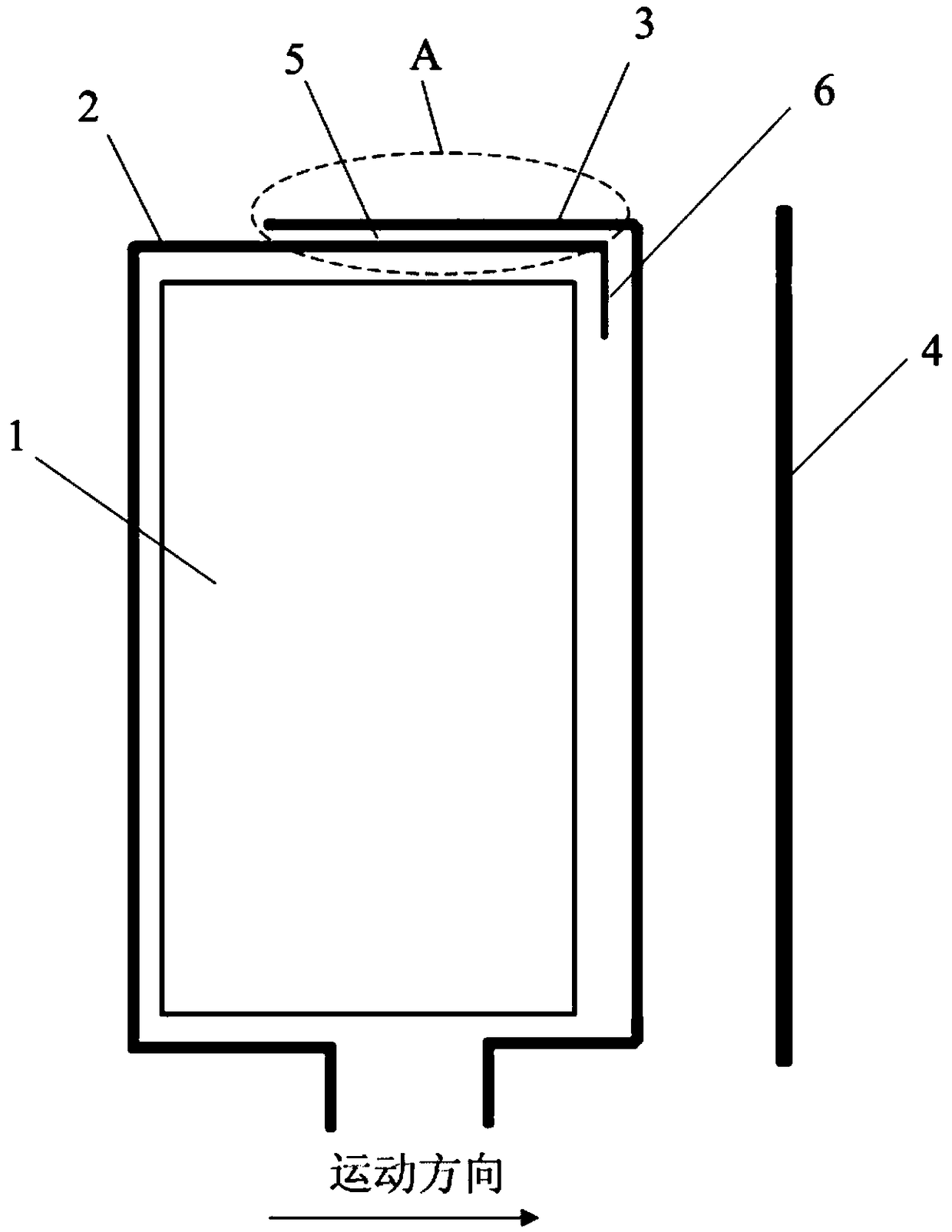

[0034] like image 3 As shown, Embodiment 2 of the present invention provides a flexible touch panel, including a main body 1 and a grounding wire arranged around the main body 1. The main body 1 is made of a flexible material. In this embodiment, the material of the main body 1 is polyethylene terephthalate Formic plastic (PET). A first fracture 5 is provided on the ground wire, and the first fracture 5 divides the ground wire into a first ground wire 2 and a second ground wire 3 . The first ground wire 2 and the second ground wire 3 are parallel to each other in the overlapping area A at the first fracture 5 . An antistatic portion 6 is provided on the first ground wire 2 or the second ground wire 3 in the overlapping area A at the first cutout 5 .

[0035] The above-mentioned antistatic part 6 is a bending line provided at the end of an extension section provided on the inner side of the first ground wire 2 and the second ground wire 3, such as image 3 shown. In this e...

Embodiment 3

[0041] Figure 4 A schematic structural diagram of the flexible touch panel provided in Embodiment 3 of the present invention, as shown in Figure 4 As shown, the difference from Embodiment 1 and Embodiment 2 is that the antistatic part 6 is a second break provided on the first ground wire 2 or the second ground wire 3 .

[0042] When passing through the EUV lamp tube 4, if the ESD phenomenon occurs, the existence of the second fracture can short-circuit the short ground wire formed after the first ground wire 2 is disconnected, and the second ground wire 3, but at this time The short circuit of the ground wire 2 is not enough to damage the product, and most of the first ground wire 2 can still be guaranteed to be disconnected, thereby ensuring the overall quality of the product.

[0043] Of course, if after evaluation, the above-mentioned second fractures will still accidentally cause injuries, the number of the above-mentioned second fractures can be set to be two, three or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com