A Substation Defect Management Method Based on Mobile Platform

A mobile platform and defect management technology, applied in the electrical field, can solve problems such as high communication costs, accuracy, rapid impact, and reduced personnel ratio, so as to improve work efficiency, reduce intermediate links, and improve processing levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

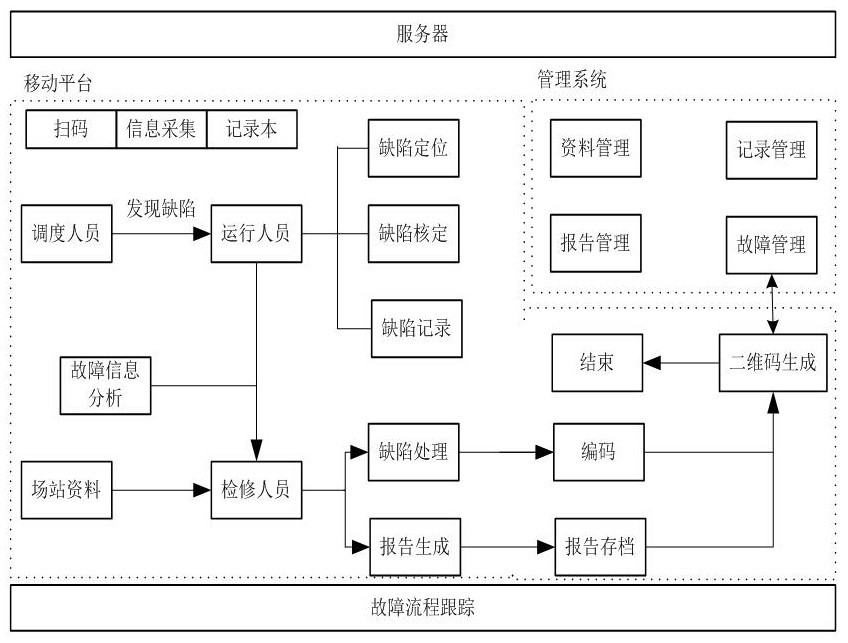

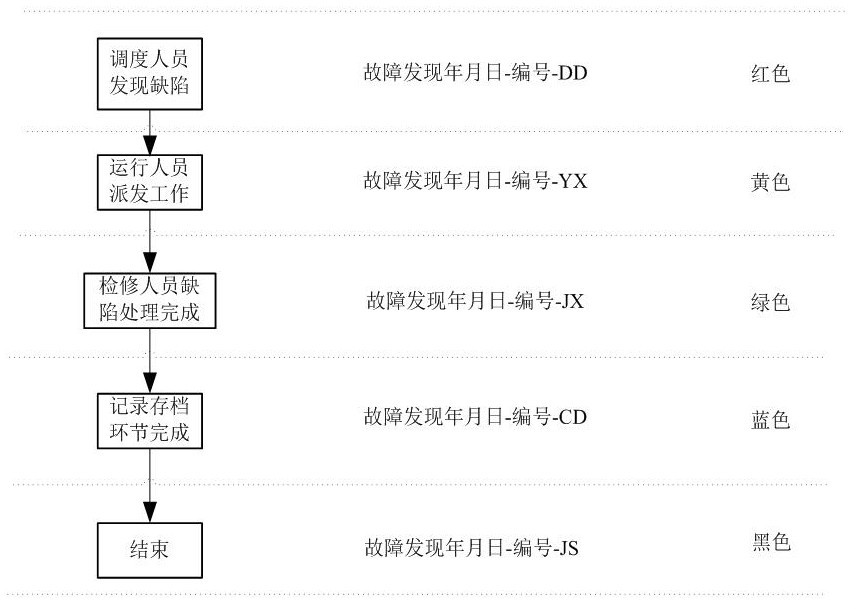

[0019] A substation defect management method based on a mobile platform. The steps are as follows: (1) Establish a substation defect management system. The system mainly includes a mobile platform, a management system and a server. The mobile platform is established based on a mobile terminal and provides three types of personnel accounts: dispatcher ( DD), operating personnel (YX) and maintenance personnel (JX); (2) The dispatcher enters the defect information found into the mobile platform, and the fault process tracking function starts; (3) The operating personnel receive the defect, perform defect location, defect verification and Defect record, after completing these steps, the system fault information analysis function starts, automatically gives similar historical defects and this defect and transfers them to the maintenance personnel; (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com