Micro tiller applied to different soil conditions and different dryland operation needs and control method

A control method and micro tillage machine technology, which is applied in the fields of application, tillage implements, agricultural machinery and implements, etc., can solve problems such as micro tillage machines are easily injured and operators, difficult to control tillage speed, and large difference in effects, etc., and achieve backward The effect of slowing down the speed, not easy to deviate, and stabilizing the overall center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0039] In the prior art, it is difficult to control the tillage speed of the micro-tiller, and the operator consumes a lot of physical strength to control the tiller. The effect of the tiller on different soil types is quite different, and the tiller is easy to injure the operator when it retreats.

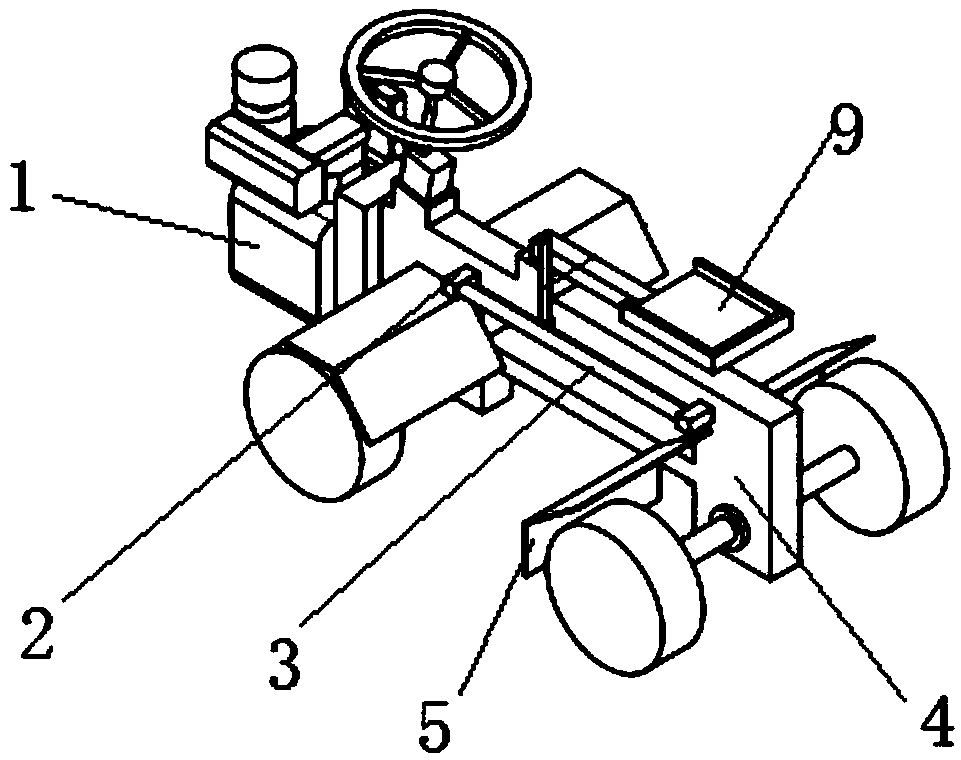

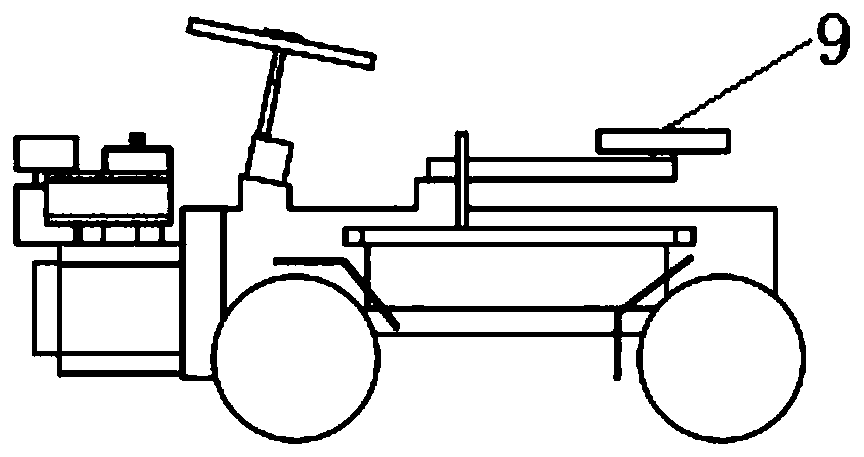

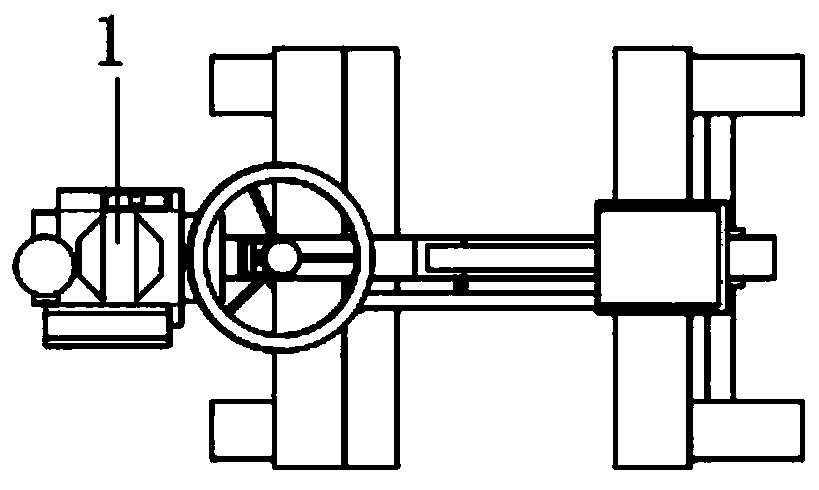

[0040] like Figure 1-Figure 5 As shown, the tiller provided by the embodiment of the present invention includes:

[0041] Tiller gearbox 1,

[0042] The output shaft head 2 on the side of the tiller gearbox 1 transmits the power to the worm 3;

[0043] The worm 3 transmits power to the constant speed rotating wheel 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com