Paddy field weeding floating granule and preparation method thereof

A granule, paddy field technology, applied in the field of pesticides, can solve the problem of inability to achieve precise and effective weeding, and achieve the effects of convenient application, good control effect, and lasting and uniform effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

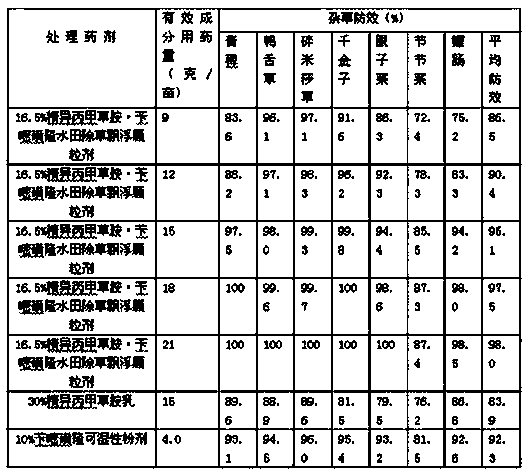

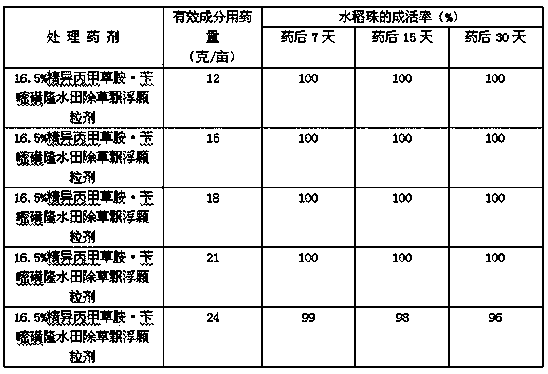

Examples

Embodiment 1

[0018] Mix 5% of refined metolachlor with 1% of alkylphenol polyoxyethylene ether phosphate, 5% of polyoxyethylene polyoxypropylene ether block copolymer, and 3% of phenylphenol polyoxyethylene ether , 5% methylated palm oil, mixed evenly, adsorbed with 20% white carbon black to form a flowable powder, and then mixed with 0.5% pyrazosulfuron methyl, 2% sodium lignosulfonate, 5% polycarboxylate Salt dispersant, 10% corn starch and glass floating beads make up 100%, mix evenly, and then pulverize by jet mill to obtain mother powder. Then the obtained mother powder is moistened with an appropriate amount of water, kneaded evenly with a kneader, and then extruded and granulated with an extrusion granulator to obtain wet granules containing refined metolachlor and pyrazosulfuron-methyl as active ingredients. After the wet granules were dried, the qualified 5.5% refined isopropyl-pyrazine floating granules for paddy field weeding were obtained.

Embodiment 2

[0020] Mix 10% of refined metolachlor with 2% of alkylphenol polyoxyethylene ether phosphate, 6% of polyoxyethylene polyoxypropylene ether block copolymer, 4% of phenylphenol polyoxyethylene ether , 8% methylated palm oil, mixed evenly, adsorbed with 22% white carbon black to form a flowable powder, and then mixed with 1.0% pyrazosulfuron methyl, 3% sodium lignosulfonate, 6% polycarboxylate Salt dispersant, 8% corn starch and glass floating beads make up 100%, mix evenly, and then pulverize by jet mill to obtain mother powder. Then the obtained mother powder is moistened with an appropriate amount of water, kneaded evenly with a kneader, and then extruded and granulated with an extrusion granulator to obtain wet granules containing refined metolachlor and pyrazosulfuron-methyl as active ingredients. The wet granules were dried to obtain qualified 11% refined isopropyl-pyrazine paddy field weeding floating granules.

Embodiment 3

[0022] Mix 15% of refined metolachlor with 3% of alkylphenol polyoxyethylene ether phosphate, 6% of polyoxyethylene polyoxypropylene ether block copolymer, 4% of phenylphenol polyoxyethylene ether , 10% methylated palm oil, mixed evenly, adsorbed with 25% white carbon black to form a flowable powder, and then mixed with 1.5% pyrazosulfuron methyl, 4% sodium lignosulfonate, 6% polycarboxylate Salt dispersant, 10% corn starch and glass floating beads make up 100%, mix evenly, and then pulverize by jet mill to obtain mother powder. Then the obtained mother powder is moistened with an appropriate amount of water, kneaded evenly with a kneader, and then extruded and granulated with an extrusion granulator to obtain wet granules containing refined metolachlor and pyrazosulfuron-methyl as active ingredients. After drying the wet granules, a qualified 16.5% refined isopropyl-pyrazine floating granule for paddy field weeding was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com