Water field weeding throwing powder and preparation method thereof

A paddy field and powder technology, applied in the field of pesticides, can solve problems such as inability to achieve precise and effective weeding, and achieve the effects of convenient pesticide application, good control effect, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

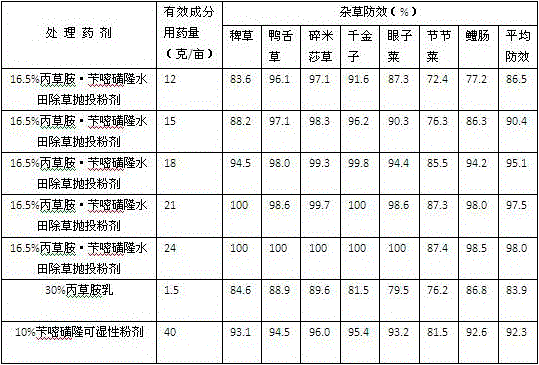

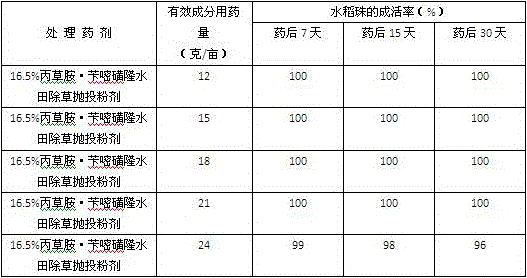

Examples

Embodiment 1

[0021] 15 parts by weight of pretilachlor and 1 part by weight of alkylphenol polyoxyethylene ether phosphate, 1 part by weight of polyoxyethylene polyoxypropylene ether block copolymer, 3 parts by weight of phenylphenol polyoxyethylene Ether, mix uniformly, absorb with the white carbon black of 20 weight parts, then with the bensulfuron-methyl of 1.5 weight parts, the sodium lignosulfonate of 2 weight parts, the sodium methylene dinaphthalene sulfonate of 1 weight part, 2 The Kathon preservative in parts by weight is uniformly mixed and pulverized by an airflow mill to obtain mother powder. Mix the parent powder and wheat straw powder supplemented to 100 parts by weight, and then mix with 10 parts by weight of paraffin and 6 parts by weight of methyl ester soybean oil to obtain a finished product of 16.5% pretilachlor-bensulfuron-methyl paddy field weeding throwing powder.

Embodiment 2

[0023] The pretilachlor of 20 parts by weight is mixed with the sorbitan phosphate of 2 parts by weight, the emulsifier Tween of 1 part by weight, the methyl naphthalene formaldehyde polymer of 3 parts by weight, with 20 parts by weight of white carbon black Adsorption, then mixed with 2 parts by weight of bensulfuron-methyl, 2 parts by weight of methylenebis(sodium methylnaphthalene sulfonate), 1 part by weight of sodium lignosulfonate, and 2 parts by weight of sodium benzoate After being pulverized by a jet mill, the mother powder is obtained. Mix the mother powder and the corn stalk powder supplemented to 100 parts by weight, and then mix them with 8 parts by weight of paraffin and 8 parts by weight of esterified soybean oil to obtain 22%% pretilachlor Bensulfuron-methyl paddy field weeding and throwing Finished powder.

Embodiment 3

[0025] Mix 10 parts by weight of pretilachlor with 2 parts by weight of sorbitan phosphate, 1 part by weight of emulsifier Tween, and 3 parts by weight of phenylphenol polyoxyethylene ether, and use 10 parts by weight of white carbon Black and 5 parts by weight of diatomite adsorption, and then with 1.5 parts by weight of bensulfuron-methyl, 2 parts by weight of methylene bis (sodium methyl naphthalene sulfonate), 1 part by weight of methylene bis Sodium naphthalenesulfonate and 2 parts by weight of sodium benzoate are uniformly mixed and pulverized by an airflow mill to obtain mother powder. Mix the mother powder with the rice straw powder supplemented to 100 parts by weight, and then mix it with 10 parts by weight of paraffin and 8 parts by weight of glyceric acid ester to obtain the finished product of 11.5% pretilachlor Bensulfuron-methyl paddy field weeding throwing powder .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com