Efficient flue gas treatment device

A technology for flue gas treatment and equipment, applied in gas treatment, gaseous effluent wastewater treatment, filtration treatment, etc., can solve the problems of different treatment effects and equipment maintenance costs, etc., to prolong the residence time and prolong the time. , the effect of delaying the flow rate

Active Publication Date: 2019-01-11

盛大环保有限公司

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The purification treatment of flue gas is a necessary process in many factories. The existing flue gas treatment equipment is mainly divided into two categories, one is based on filtration and a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

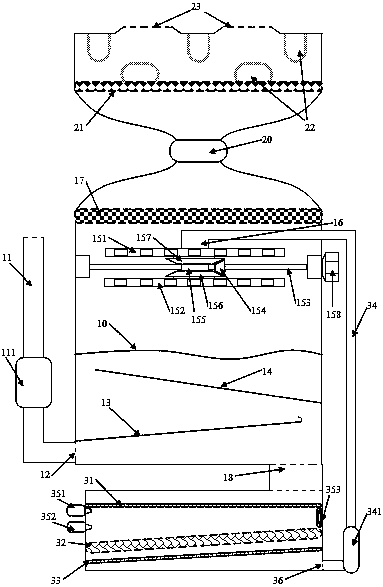

The invention relates to an efficient flue gas treatment device, which comprises a spraying and air-washing device, a pressurized adsorption device, a photocatalyst device and a water treatment device. By setting the air-washing and spraying components with a specific structure, the air-washing efficiency is greatly improved, and spraying is directly carried out after air-washing, supplementing the effect of air-washing. Thereby, the treatment effect of flue gas is improved. The photocatalytic treatment is carried out after the sprayed and air-washed flue gas is adsorbed and filtered such thatthe treatment of the flue gas is more sufficient. By circulating the spray water, secondary pollution is avoided and resources are effectively utilized.

Description

technical field [0001] The invention belongs to the field of gas purification and environmental protection, and in particular relates to high-efficiency flue gas processing equipment. Background technique [0002] The purification treatment of flue gas is a necessary process in many factories. The existing flue gas treatment equipment is mainly divided into two categories, one is based on filtration and adsorption, and the other is based on water washing and gas treatment. The treatment effects of the two types of equipment are not the same, and the maintenance costs of the equipment are also different. If the two are further integrated, the advantages of the two can be fully utilized, but how to combine them with better quality has become a problem to be solved by researchers. When water vapor treatment equipment is used, if the water body is discharged directly, it will cause secondary pollution. Therefore, how to properly treat the treated water is also a problem to be s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B01D53/75B01D53/78B01D53/82B01D53/76B01D53/86C02F9/08C02F103/18

CPCB01D53/75B01D53/76B01D53/78B01D53/82B01D53/86B01D2251/104B01D2258/0283C02F1/001C02F1/283C02F1/66C02F9/00C02F2103/18

Inventor 陈雪飞

Owner 盛大环保有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap