Rotating edible salt screening device

A rotary, salty technology, applied in sieves, solids separation, grids, etc., can solve problems such as limitations of applicability and practicability, affecting processing efficiency, difficulty in mass production, etc., saving manpower and material resources, improving Efficiency and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

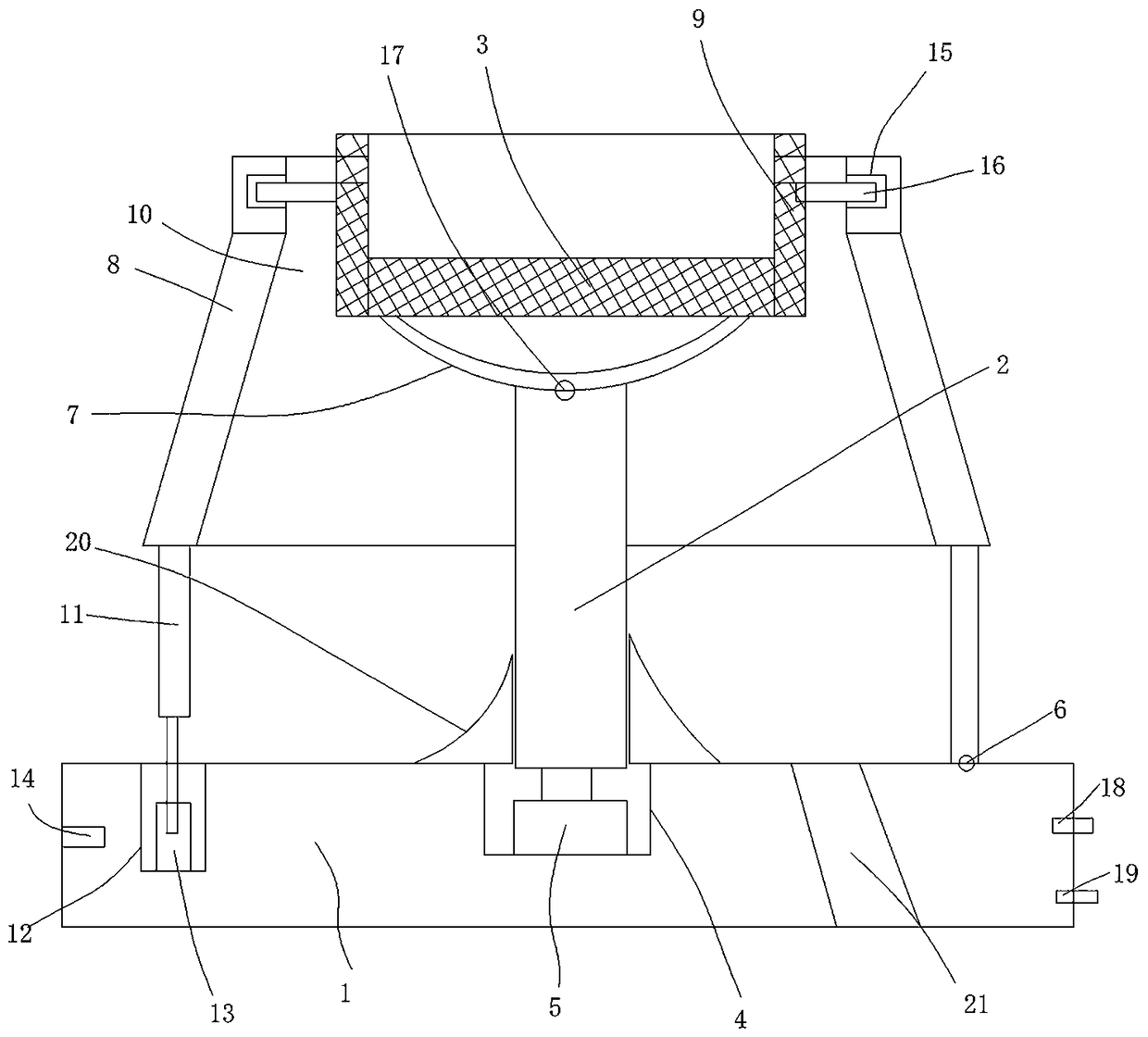

[0017] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0018] See figure 1 , a rotary type edible salt sieving device, comprising a base 1, a rotating column 2 arranged on the base 1 and a screen 3 arranged on the rotating column 2, a rotating Recessed cavity 4, a forward and reverse rotation motor 5 is arranged in the rotation cavity 4, the bottom end of the rotation column 2 is fixed on the forward and reverse rotation motor 5, and an arc is arranged on the rotation column 2 Shaped bracket 7, in the present embodiment, arc-shaped bracket is cross-shaped, and the two ends of described arc-shaped bracket 7 are respectively fixedly connected to the two ends of the bottom surface of described screen cloth 3, and trumpet-shaped baffle plate 8 is also provided with, in the The edge of the top surface of the screen 3 is fixed with a cylindrical mesh 9, and a gap 10 is arranged between the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap