Automatic rotor cutting machine

A cutting machine and cutting mechanism technology, which can be applied to household appliances, other household appliances, household components, etc., can solve the problems of automatic feeding and unloading, and achieve high practical value, reliable clamping, and reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

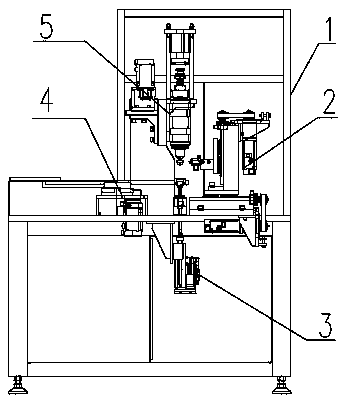

[0028] Such as figure 1 and figure 2 As shown, an automatic rotor cutting machine includes a frame 1, and the frame 1 is provided with a feeding mechanism 4 and a feeding mechanism 3;

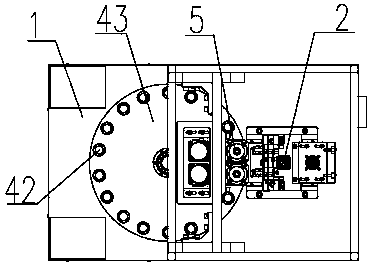

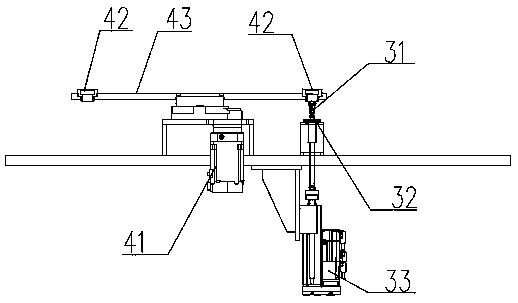

[0029] Such as image 3 As shown, the feed mechanism 4 includes a feed tray 43 horizontally arranged on the frame 1, and a rotary drive unit 41 that drives the feed tray 43 to rotate around the vertical direction. A number of feed holes 42 vertically penetrating the feed tray 43 are distributed.

[0030] Such as image 3 As shown, the feeding mechanism 3 includes two jacking heads 31 located below the tray 43, and the feeding mechanism 3 also includes a lifting drive unit 33 that drives the jacking heads 31 to pass through the corresponding material holes 42; The lifting head 31 is provided with a length adjusting device 32, which adjusts the length of the lifting head 31 to improve the accuracy of feeding.

[0031] Such as figure 1 As shown, it also includes a clamping mechanism 5 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com