Open type 3D printer based on hot melt accumulation

A 3D printer and hot-melt deposition technology, applied in 3D object support structures, coating devices, processing heating elements, etc., can solve the problems of empty burning of print head devices, extrusion of consumables, burning of print heads, etc., and achieve easy assembly. , The component composition is less, the effect of promoting straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is done as preferred specific description:

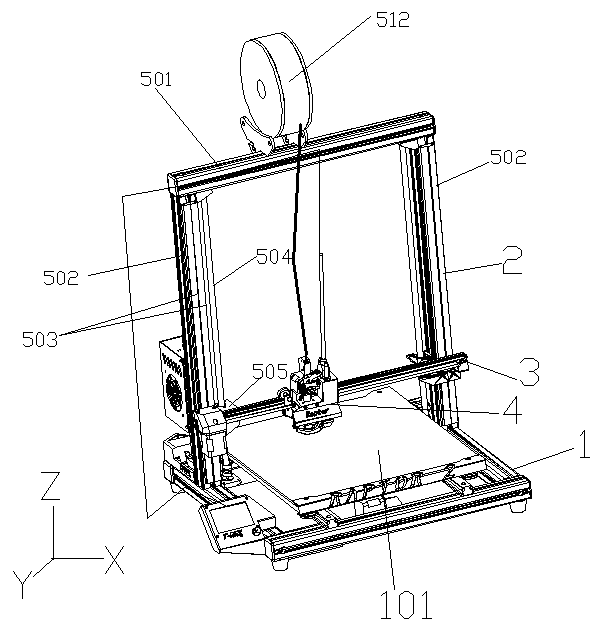

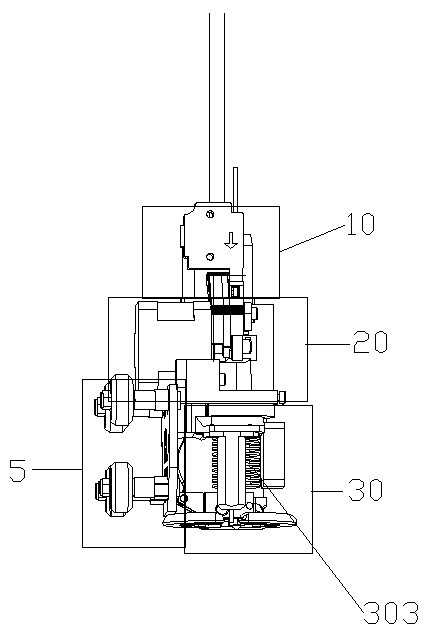

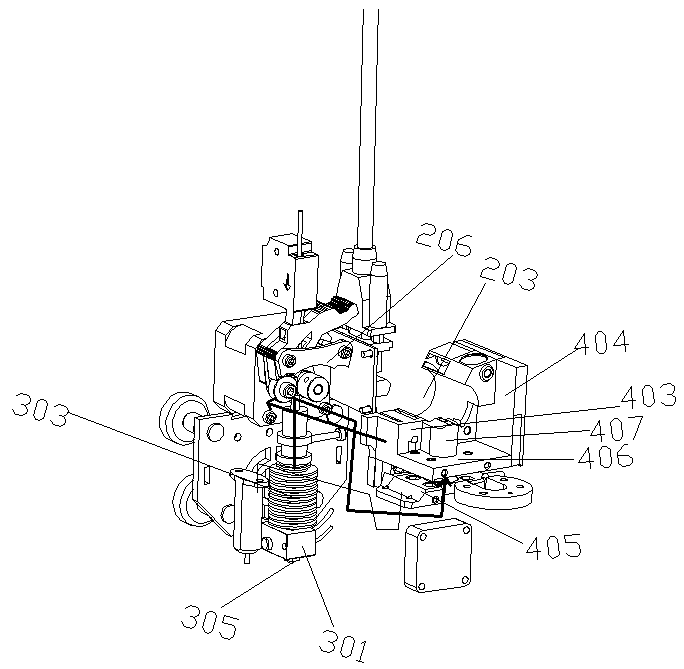

[0040] Such as figure 1 As shown, an open 3D printer based on hot-melt deposition includes a printing table (1), a Z-axis printing frame (2), and an X-axis printing frame (3). The connection mode and operation mode of the head on the X-axis printing frame, as well as the structure and operation mode of the FDM printing head. In addition, the printing table (1) and the Z-axis printing frame (2) are all existing technologies. For details, please refer to FDM The printer models are open type. Specifically, there are Chuangxiang 3D series and XINKEBOT OrcaPro series. First of all, the printing table has a square bottom guide rail frame to support the Z-axis printer, and there are 2 to 3 Y-axis guide rails in the middle. It is used to control the forward and backward movement of the printing and forming table (101) on the Y-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com