Container for keeping easily oxidized mixed content objects

A content and easy-to-oxidize technology, applied in the field of containers for storing the content of the mixture, can solve problems such as unsatisfactory, oxidation failure, complexity, etc., and achieve the effects of avoiding drug efficacy failure, increasing use time, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

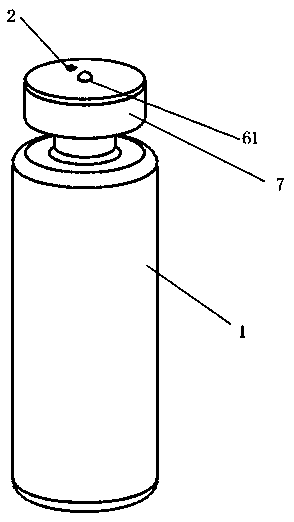

[0044] Such as figure 1 The shown container for storing easily oxidizable mixed contents comprises a rigid container 1 which is a bottle body having a top, a bottom and an opening 2 on the top.

[0045] The bottom of the bottle body is concave, which can not only leave space for the multi-stage extrusion equipment but also keep the air pressure inside the bottle stable. The bottle body is made of anti-oxidation glass to further prevent the oxidation of the contents. The opening of the bottle body It can be poured directly or combined with other parts, such as adding a dropper as an eye drop container, adding a straw as an oral liquid container, etc.

Embodiment 2

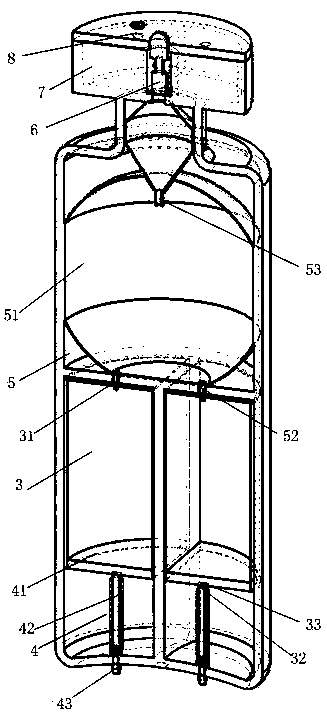

[0047] Such as figure 2 The shown rigid container 1 includes a storage chamber, the storage chamber is arranged at the bottom of the rigid container 1, and the storage chamber is divided into a plurality of independent storage chambers 3, and the bottom ends of the independent storage chambers 3 are provided with multi-stage extrusion Equipment 4, the top of the independent storage chamber 3 is provided with a top one-way valve body 31, and the multi-stage extrusion device 4 squeezes the contents of the independent storage chamber 3 into the flexible mixing chamber 5 through the top one-way valve body 31 ;

[0048]The flexible mixing chamber 5 is provided with a flexible mixing bag 51, and the bottom end of the flexible mixing bag 51 is provided with a plurality of flexible one-way passages 52, and the flexible one-way passages 52 are connected with the top one-way valve body 31, so The top of the flexible mixing bag 51 is connected to the extraction device 6 through a one-w...

Embodiment 3

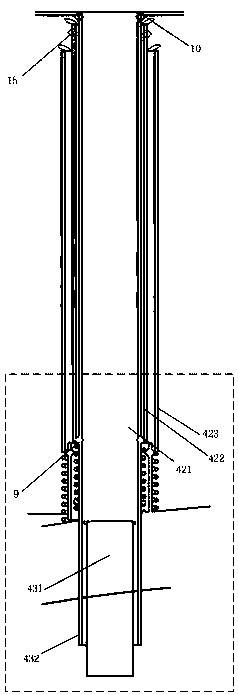

[0051] Such as figure 2 , 3 The bottom of the independent storage chamber 3 shown in . The multi-stage extruding device 4 includes an extruding plate 41, a multi-stage elastic push rod 42 and an extruding control knob 43. The extruding plate 41 is arranged in the independent storage chamber 3, and the extruding plate 41 is attached It is made of elastic material, which can fully seal and move with the independent storage chamber 3 to ensure that the inside of the independent storage chamber 3 is still sealed when the extrusion plate 41 moves, and the multi-section elastic push rod 42 passes through the bottom one-way valve body 33 is in contact with the extrusion plate 41, and the multi-section elastic push rod 42 is provided with a suction cup, which can be firmly adsorbed on the extrusion plate 41. The extrusion control button 43 and the multi-section elastic push rod 42 Connect and control the multi-section elastic push rod 42.

[0052] The multi-stage elastic push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com