Preparation method of transparent and colorless composite latex condom with high insulating property and high strength

A composite latex and high-strength technology, applied in the direction of male contraceptives, etc., can solve the problems of lack of interaction between functional groups and rubber molecules, inability to fully stretch and spread, inability to be transparent and colorless, and achieve high market acceptance and spread Probability reduction and inhibition, increase the effect of sexual life pleasure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

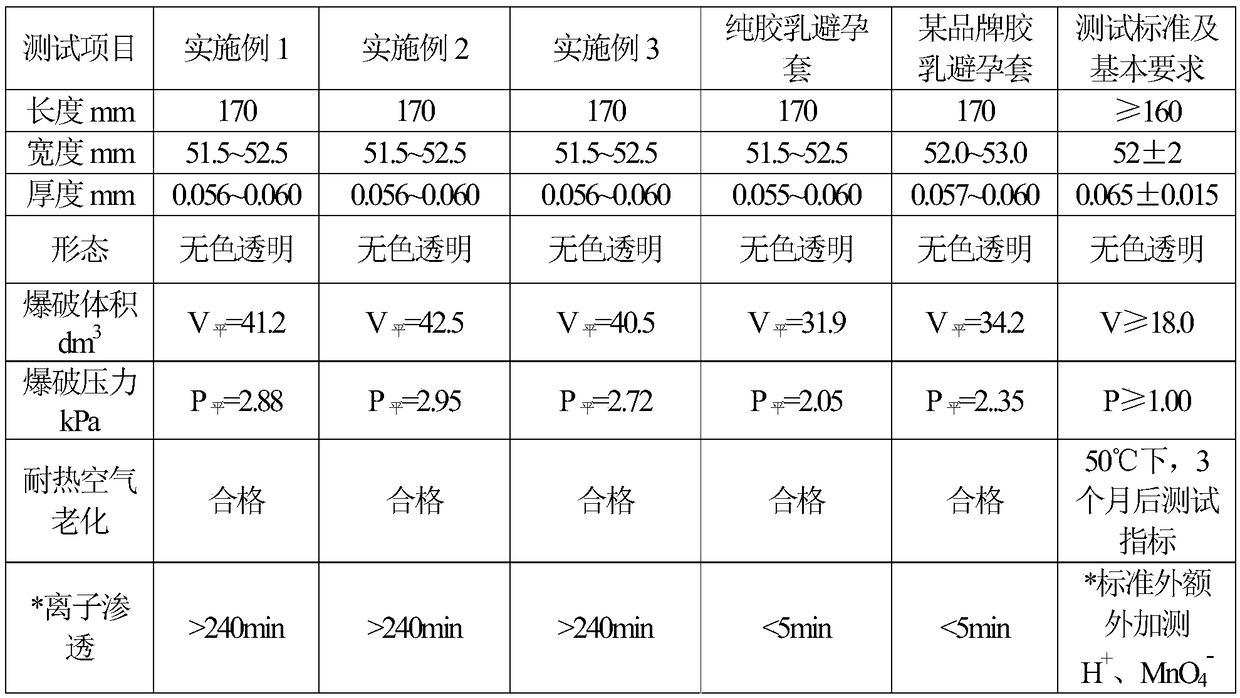

Examples

Embodiment 1

[0036] In the present embodiment, the preparation method of the transparent colorless composite latex condom with high insulation and high strength is as follows:

[0037] A total of 10 groups of CVD-grown graphene copper foil plates (100×100 cm) were connected to electrode clips as cathodes. 10 groups of graphite flakes (100×100cm) are used as anodes, corresponding to the cathodes one by one, and placed in relative combination. Then spray polyvinylpyrrolidone (average molecular weight: 450,000) hydrogel solution with a mass concentration of 25% on the copper foil panel, with a thickness of about 0.1 mm. Put all the panels into the glass tank of the sonicator to hold the water, connect the power supply, and turn on the sonicator. The electrolysis voltage is 20V, and the water temperature is controlled at about 80°C. Ultrasonic power density is 1W / cm 2, the ultrasonic frequency is 40kHz. Ultrasound shatters and falls off the graphene, and at the same time electrolyzes the w...

Embodiment 2

[0039] In the present embodiment, the preparation method of the transparent colorless composite latex condom with high insulation and high strength is as follows:

[0040] A total of 10 groups of CVD-grown graphene nickel plates (100×100 cm) were connected to electrode clips as cathodes. 10 groups of graphite flakes (100×100cm) are used as anodes, corresponding to the cathodes one by one, and placed in relative combination. Then, the polyvinylpyrrolidone (average molecular weight: 850,000) hydrogel solution with a mass concentration of 30% was sprayed on the nickel foil panel with a thickness of about 0.08mm. Put all the panels into the glass tank of the sonicator to hold the water, connect the power supply, and turn on the sonicator. The electrolysis voltage is 15V, and the water temperature is controlled at about 70°C. Ultrasonic power density is 0.8W / cm 2 , the ultrasonic frequency is 40kHz. Ultrasound shatters and falls off the graphene, and at the same time electrolyz...

Embodiment 3

[0042] In the present embodiment, the preparation method of the transparent colorless composite latex condom with high insulation and high strength is as follows:

[0043] A total of 10 groups of CVD-grown graphene quartz plates (100×100 cm) were connected to electrode clips as cathodes. In addition, a total of 10 groups of CVD-grown graphene quartz plates (100×100 cm) were connected with electrode clips as anodes, corresponding to the cathodes one by one, and placed in relative combinations. Then spray the polyvinylpyrrolidone (average molecular weight: 1,100,000) hydrogel solution with a mass concentration of 35% on the nickel foil panel, with a thickness of about 0.06mm. Put all the panels into the glass tank of the sonicator to hold the water, connect the power supply, and turn on the sonicator. The electrolysis voltage is 10V, and the water temperature is controlled at about 60°C. Ultrasonic power density is 0.8W / cm 2 , the ultrasonic frequency is 40kHz. Ultrasound sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com