Grooving method for underground water pollution stop control

A groundwater pollution and trough forming technology, which is applied in infrastructure engineering, excavation, protection devices, etc., can solve problems such as short service life, increased engineering cost, and long construction period, so as to control engineering cost, facilitate secondary utilization, and improve The effect of groove quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

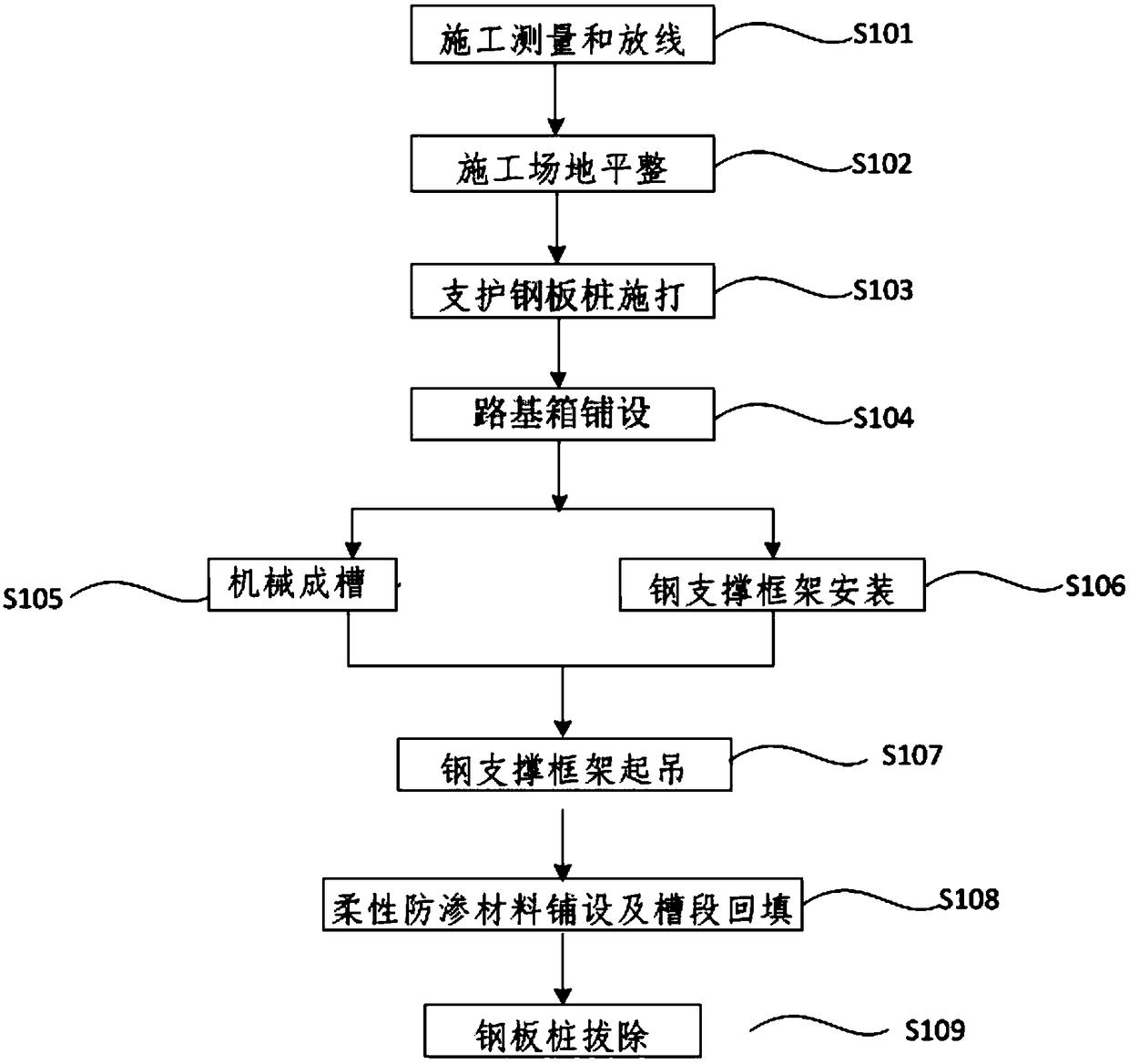

[0036] This embodiment provides a trough forming method for groundwater pollution prevention and control, and the trough forming method includes:

[0037] S101. After geotechnical engineering survey and pollution investigation in the early stage of the site, the designer proposes the anti-seepage path and the anti-seepage depth, and the construction party conducts site measurement and laying out. The anti-seepage central axis is dotted with white ash. When the path has construction obstacles in space, communicate with the supervisor, the construction party and the designer in time for changes.

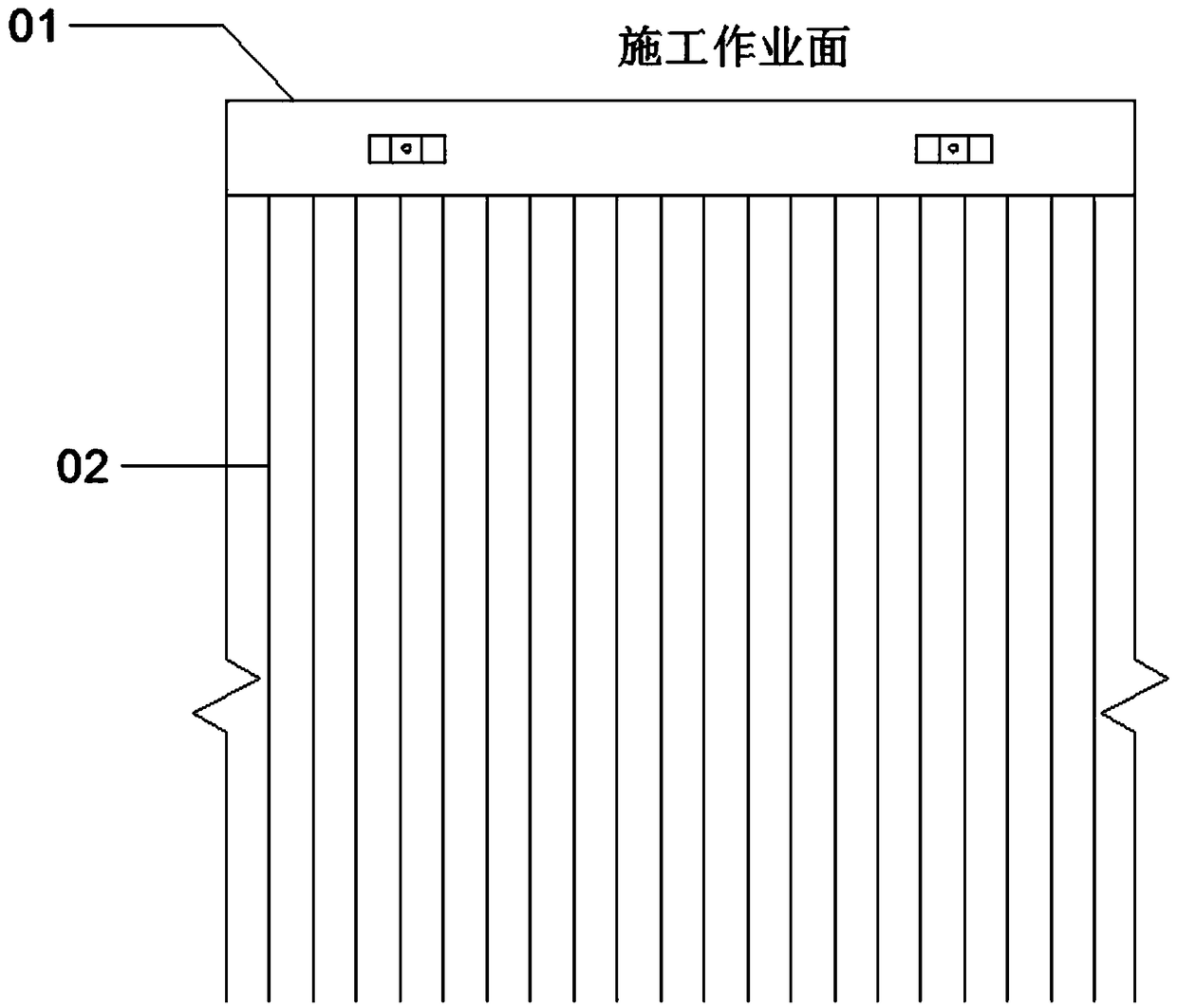

[0038] S102. Clean up and level the construction work surface. Bulldozers and excavators are required to clean up the miscellaneous fill, organic soil, large gravel, tree roots, etc. within 500mm of the work surface. The width direction is combined with the maximum width that the site can provide. Provide a construction work surface with a width of 8 meters.

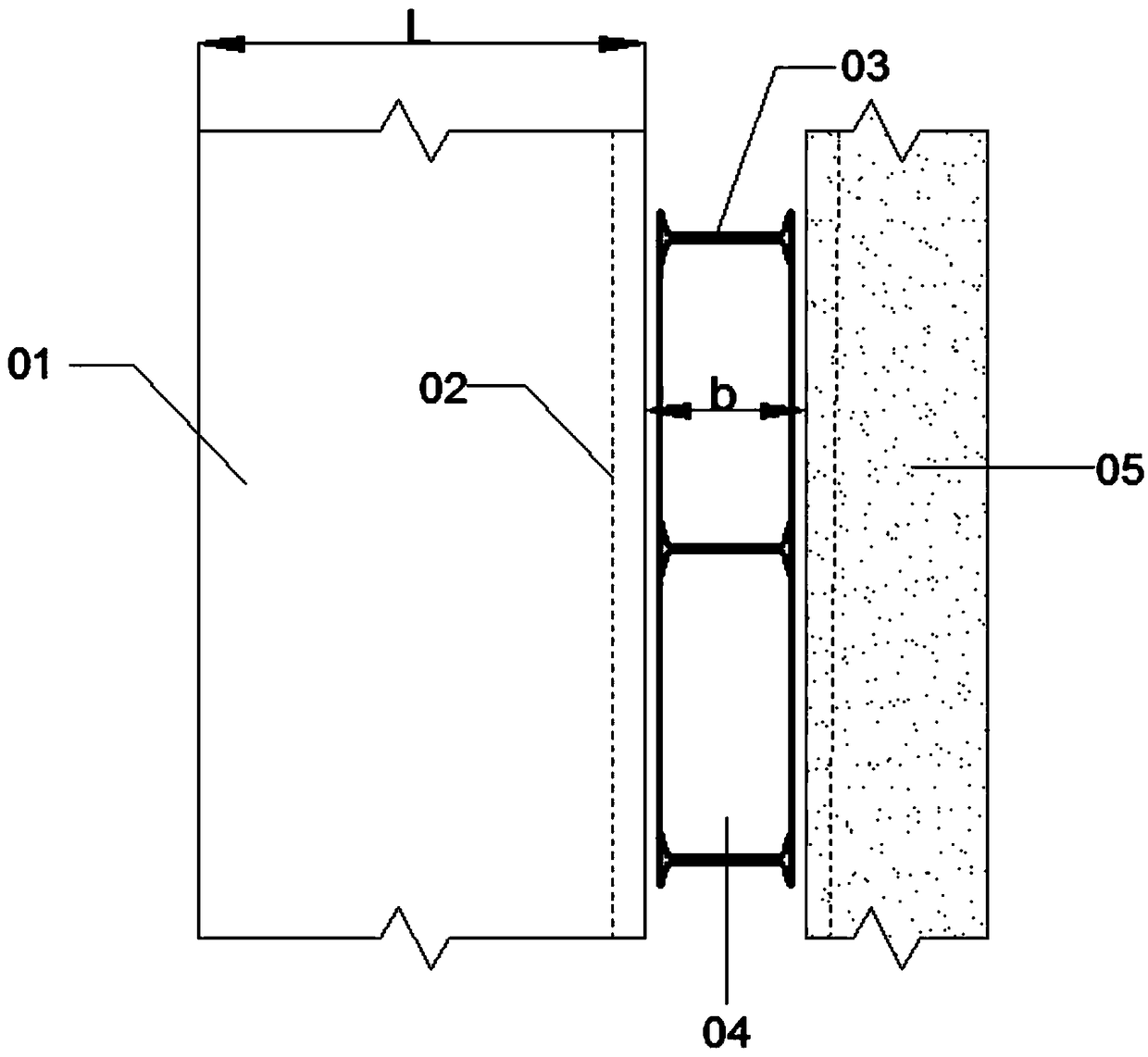

[0039] S103. The full length of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com