Water-wave-shaped fluorocarbon spray-coated electrolytic plate ceiling and manufacture and installation method thereof

An installation method and wave-shaped technology, which is applied to ceilings, building components, buildings, etc., can solve the problems of high bearing capacity requirements of ceiling keels and ceilings, difficulty in meeting thin-walled and arc-shaped requirements, and difficult handling of splicing joints. , to achieve the effect of saving materials and construction costs, light weight and low labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

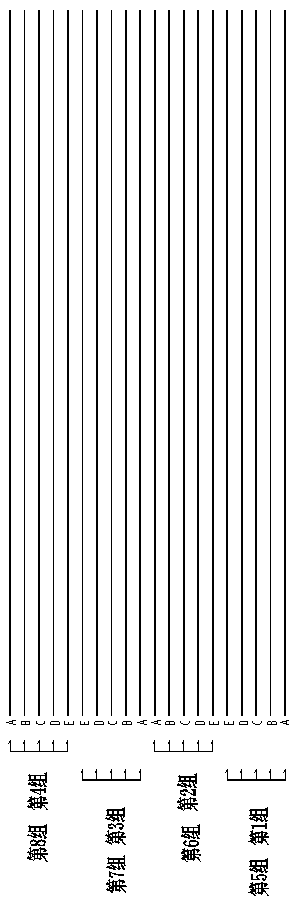

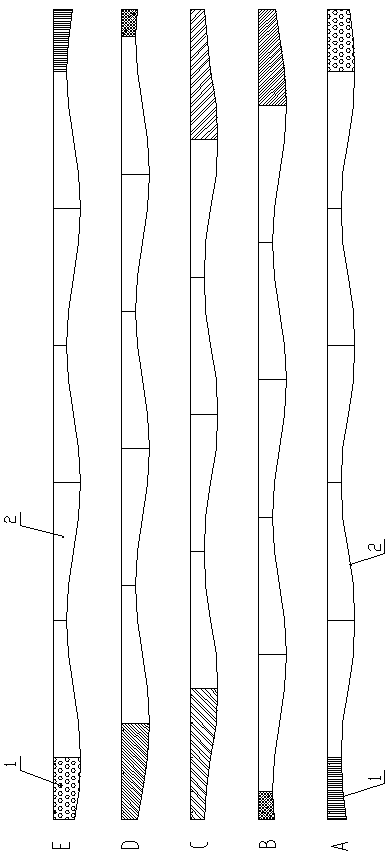

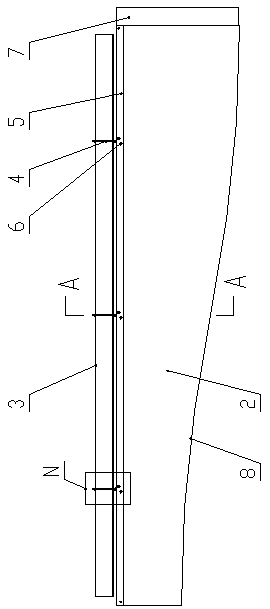

[0036] like Figure 1-Figure 6 As shown, the water ripple wavy fluorocarbon sprayed electrolytic plate ceiling of the present invention includes several groups of ceiling components arranged along the front and rear directions, and each group of ceiling components includes A, B, C, D, E arranged in sequence along the front and rear directions. Five rows of hanging plate components, the ceiling components are divided into groups 1, 2, 3..., n from front to back, n is a natural number, and the five rows of hanging plate components in an odd group are A→B→C→D → Arranged in E, the five rows of hanging plate components in the even group are all arranged in E→D→C→B→A;

[0037] A, B, C, D, and E five rows of suspension panels include non-standard suspension panels 1 at the left and right ends, several standard suspension panels 2 connected in series in the middle, and non-standard suspension panels 1 and several standard suspension panels connected in series. The upper edge of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com