A method for judging the timing of dpf regeneration of diesel engine based on carbon load

A technology of regeneration timing and DPF, applied to machines/engines, mechanical equipment, engine components, etc., to achieve reliable estimation results and improve fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

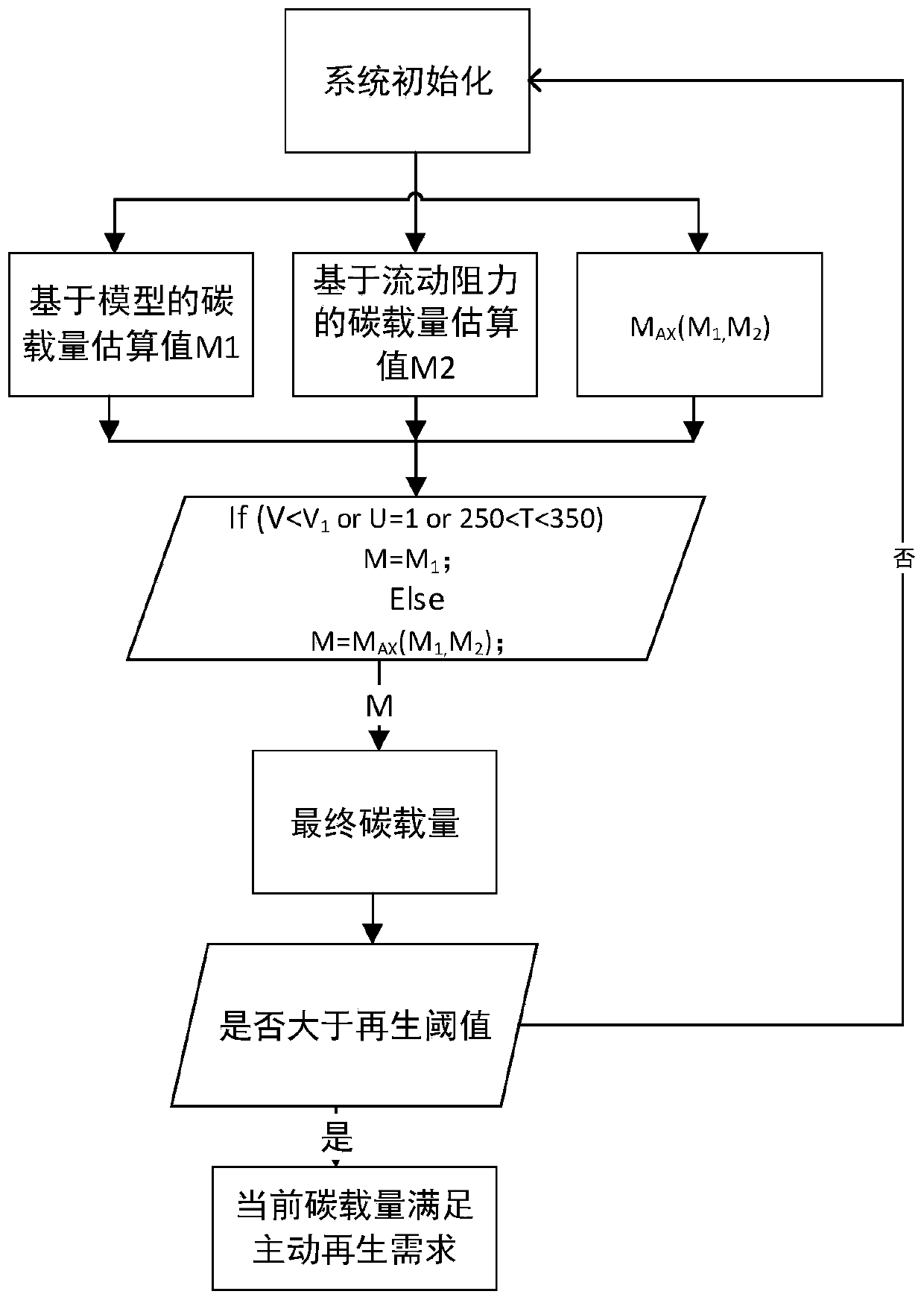

[0060] Such as figure 1 and figure 2 Shown, the judging method of the diesel engine DPF regeneration opportunity based on carbon load of the present invention, comprises the steps:

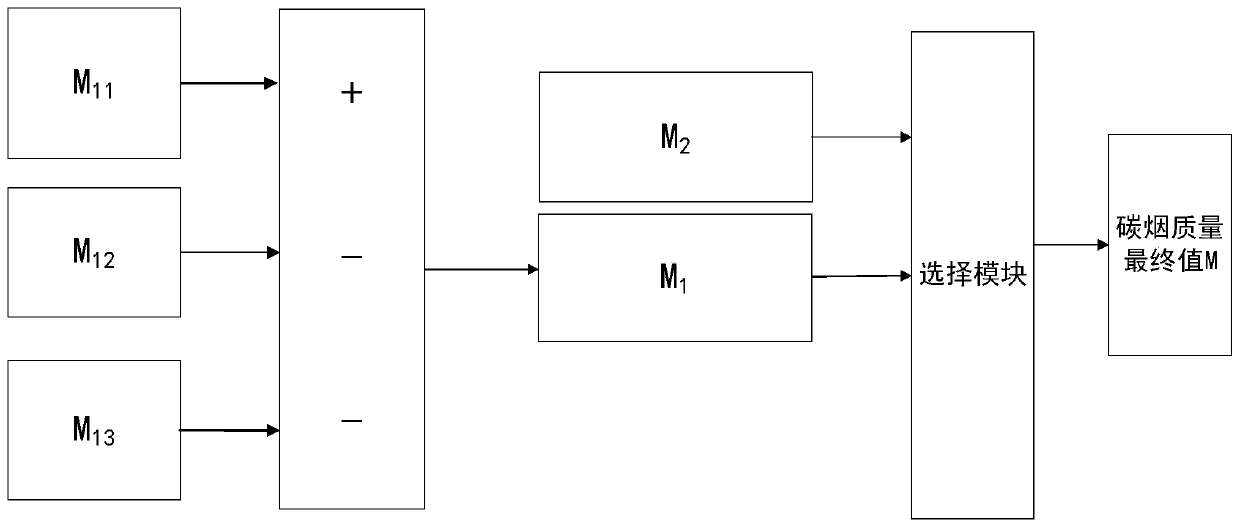

[0061] Calculate the model-based soot storage mass M 1 , including the following steps:

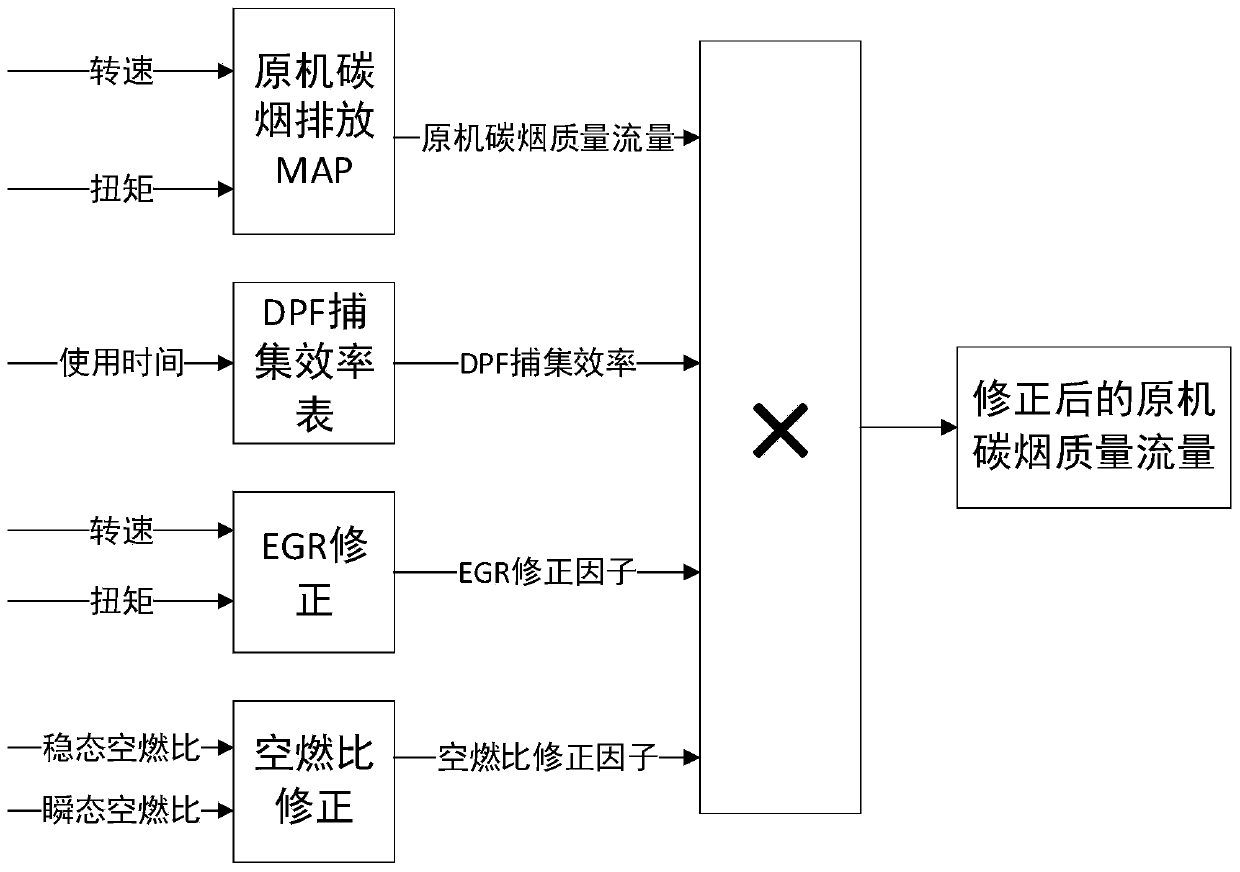

[0062] Calculation and correction of the soot mass flow rate M of the original machine 11 ,Such as image 3 shown, including the following steps:

[0063] Query the soot emission MAP map of the original engine according to the engine speed and torque, and obtain the corresponding soot mass flow rate M of the original engine 10 ;

[0064] Query the EGR correction MAP according to the engine speed and torque to obtain the correction amount K of the EGR rate to soot 1 ;

[0065] Query the air-fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com