A supercharged engine exhaust manifold

A technology of supercharged engine and exhaust manifold, applied in combustion engine, engine control, engine components, etc., can solve the problems of increasing power, increasing exhaust energy, shortening the length of exhaust pipe, etc., to enhance low-speed power , the effect of increasing exhaust energy and reducing exhaust interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

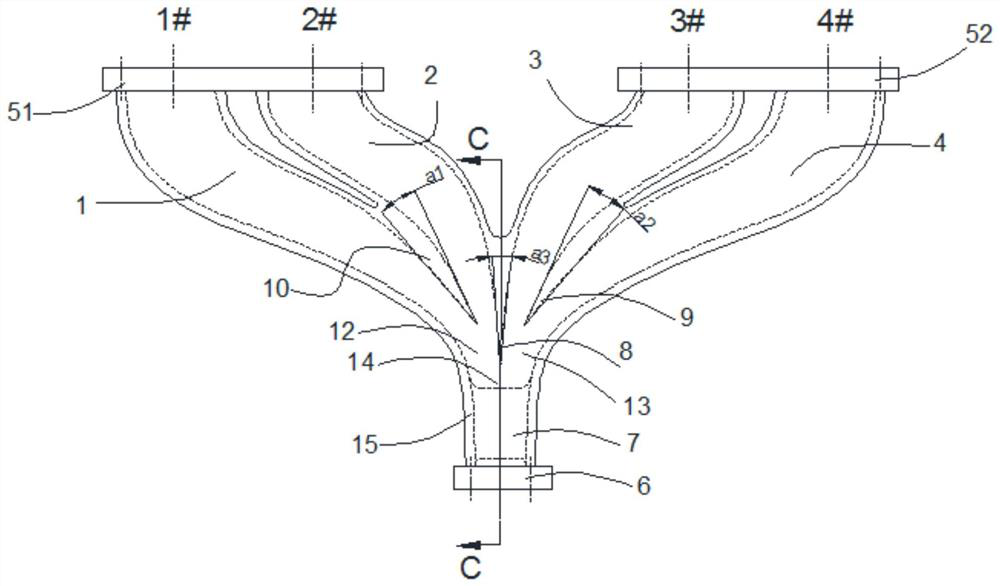

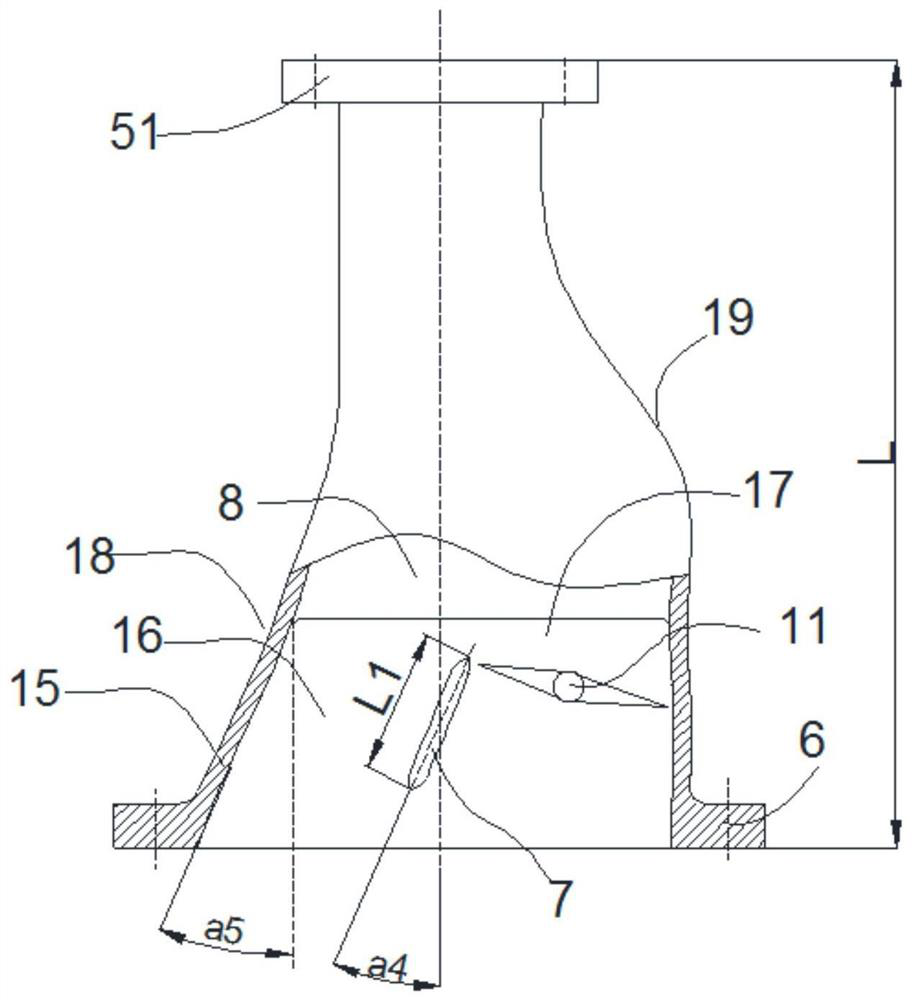

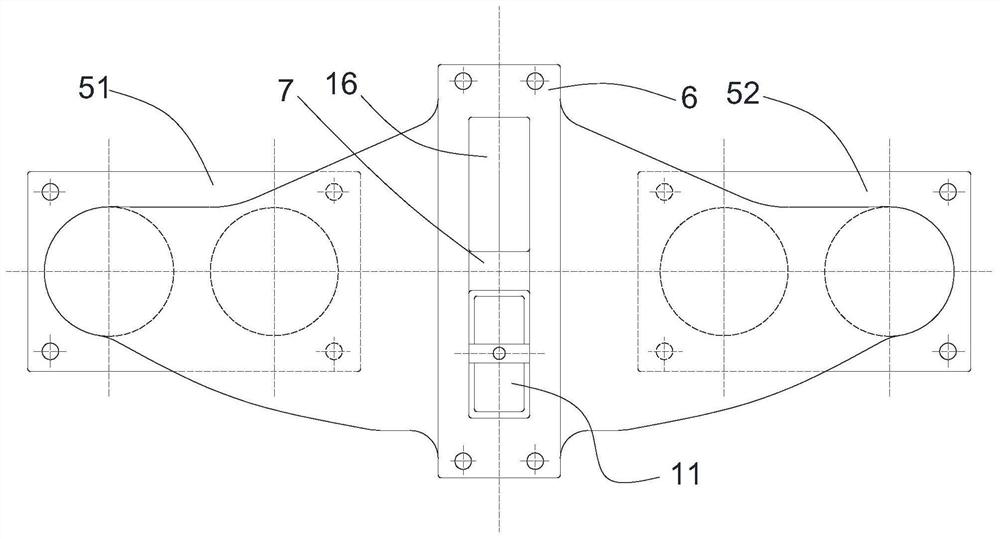

[0027] Such as figure 1 , figure 2 as well as image 3As shown, in order to reduce the mutual interference of exhaust gas between cylinders and improve scavenging, in the design scheme meeting this requirement, the first exhaust manifold 1 and the second exhaust manifold 2, the third exhaust manifold 3 and the fourth The exhaust manifolds 4 are merged firstly to form the first merged part 12 and the second merged part 13 respectively, and due to the ignition sequence, the inter-cylinder interference is reduced to the greatest extent. The convergence angle a1 of the first convergence part 10 and the convergence angle a2 of the second convergence part 9 are less than 20°, and the ratio of the flow area after convergence to the original flow area ranges from 0.85 to 1.0 (that is, the first exhaust manifold 1 is in the first The ratio of the flow area at the bottom of the converging portion 10 to the flow area at the A inlet flange 51 is in the range of 0.85 to 1.0; other exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com