A method for plugging a blast hole

A blast hole blocking and blast hole technology, applied in blasting and other directions, can solve the problems of difficult construction work and unsatisfactory clogging effect, and achieve the effects of being beneficial to environmental protection, improving construction efficiency and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

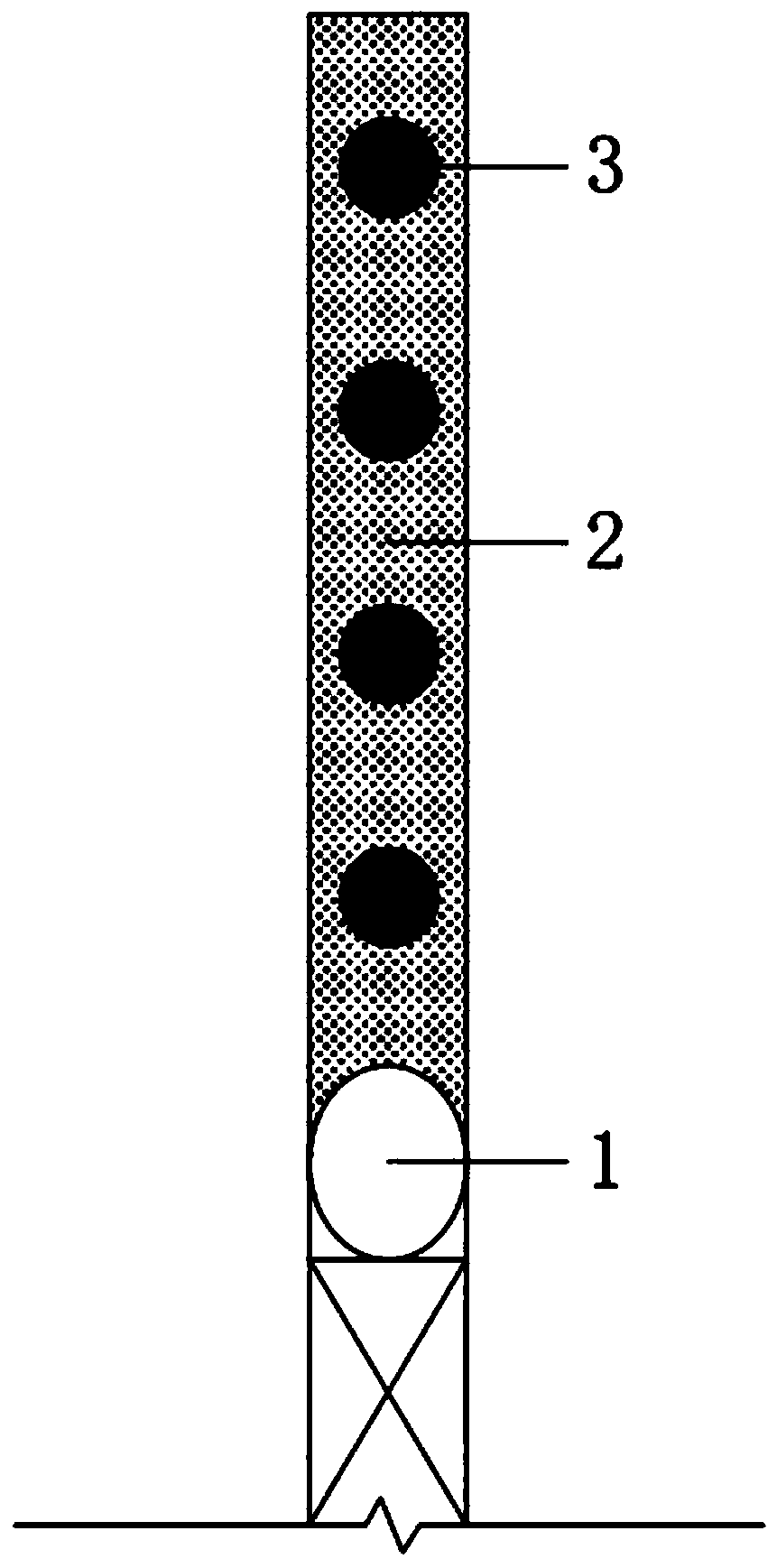

[0024] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as figure 1 As shown, in a quarry, the drilling and blasting method is used to mine stone. The diameter of the blast hole is 90mm, the depth of the blast hole is 2.5m, and the length of the plugging section is 0.8m. The construction method adopts the following steps:

[0025] Step 1. Determine the number and diameter of spherical expansion bags 2 to be placed in the blockage section according to the length of the blockage section and the diameter of the blast hole, and collect drilling cuttings at the construction site. The distance between adjacent spherical expansion bags is 0.15m, and the first The spherical expansion bag is 0.15m away from the air spacer, the bottom of the uppermost spherical expansion bag is 0.10m away from the top of the blast hole, the number of spherical expansion bags is 4, and the diameter of the dry sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com