High-precision photoelectric sensor angle detection system, calibration method and detection method

A photoelectric sensor and angle detection technology, applied in the detection field, can solve the problems of high cost, complex calculation, unsuitable for mass production, etc., and achieve the effect of low cost, simple process, and large-scale production application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

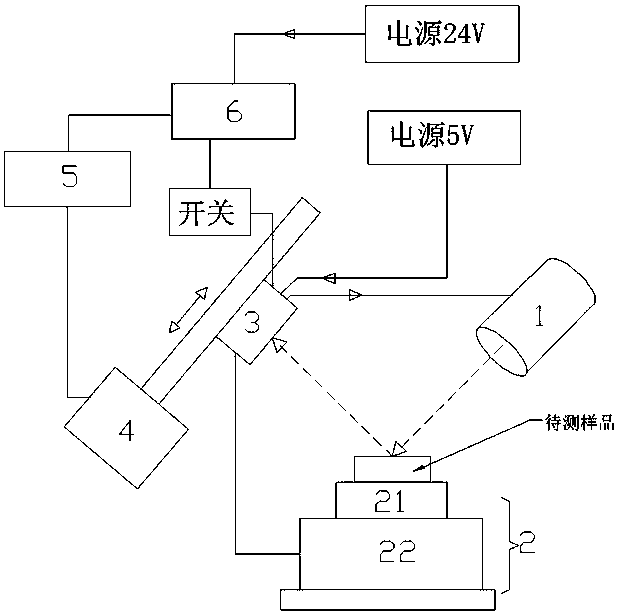

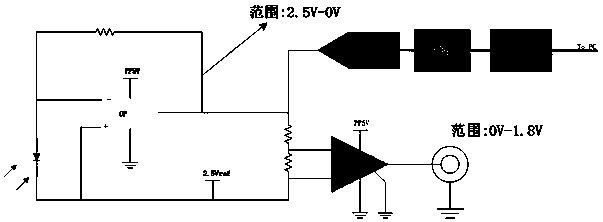

[0032] Such as Figure 1 to Figure 2As shown, the high-precision photoelectric sensor angle detection system of the present invention includes a laser transmitter 1, a product machine 2, a PSD board 3, and a product to be tested is fixed on the product machine 2, and the laser transmitter 1 The product to be tested is irradiated, the PSD board 3 is located on the laser light path reflected by the product to be tested and the plate surface of the PSD board 3 is perpendicular to the laser light path reflected by the product to be tested in the initial state, when the external force makes the product to be tested When deformation occurs, the incident angle or reflection angle of the laser light on the product to be tested changes, the light spot formed by the laser reflected by the product to be tested on the PSD board 3 moves, and the external output voltage of the PSD board 3 changes. According to the change of the voltage value, the change of the angle value of the product und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com