Test evaluation method for engine super knock safety margin

A super-knocking, safety margin technology, applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as engine failure, rising after-sales costs, failure of related parts and systems, etc., to reduce Parts failure, novel and reliable method, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

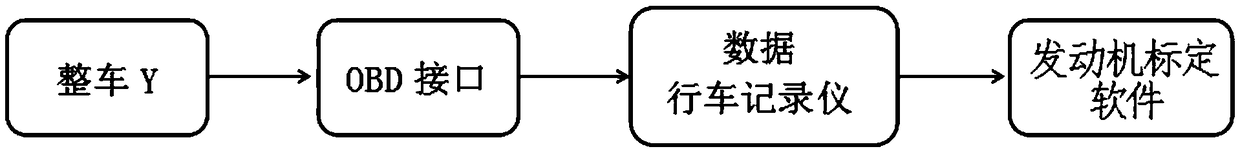

[0025] Such as Figure 1 to Figure 4 As shown, the test evaluation method of the engine super knock safety margin design includes the following steps:

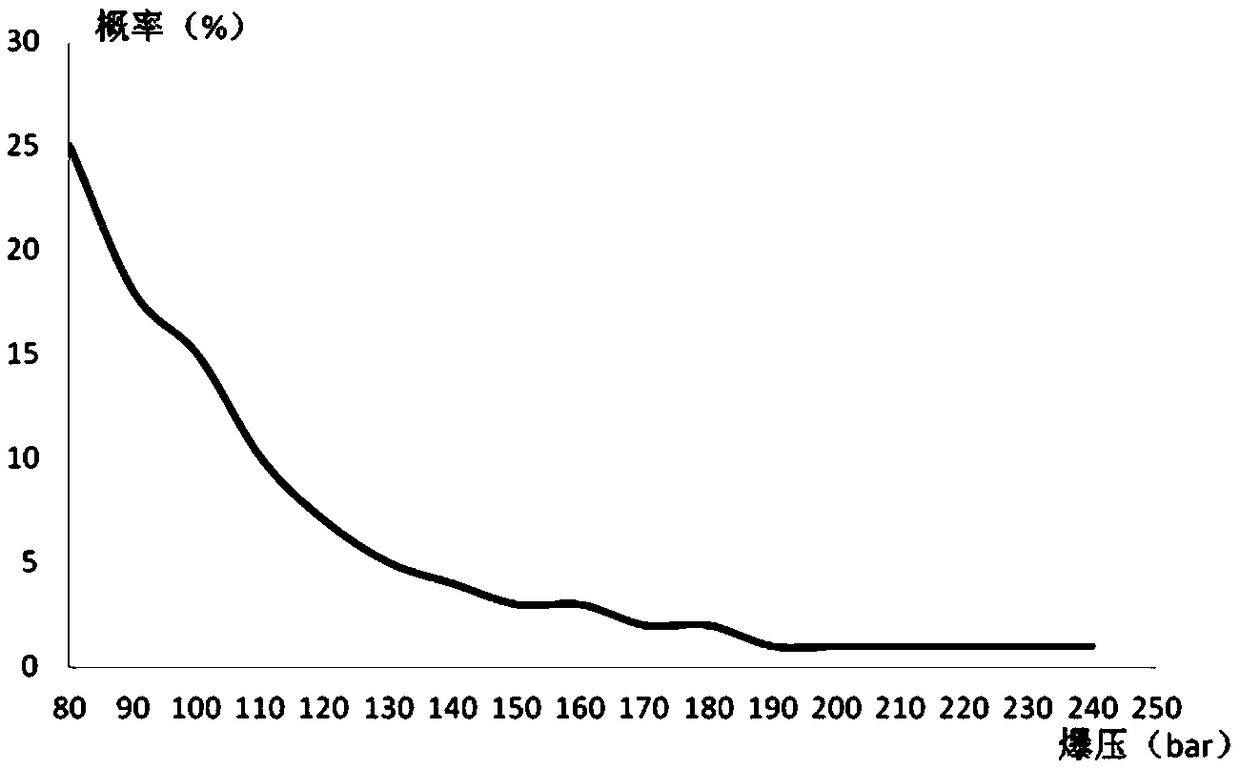

[0026] By monitoring the super knock in the engine bench test, collecting the detonation pressure data, and determining the probability curve of the detonation pressure distribution of the super detonation of the engine;

[0027] By monitoring the occurrence of super-knock in the vehicle durability test and counting the frequency of super-knock, the frequency of super-knock under a certain endurance mileage of the vehicle can be determined;

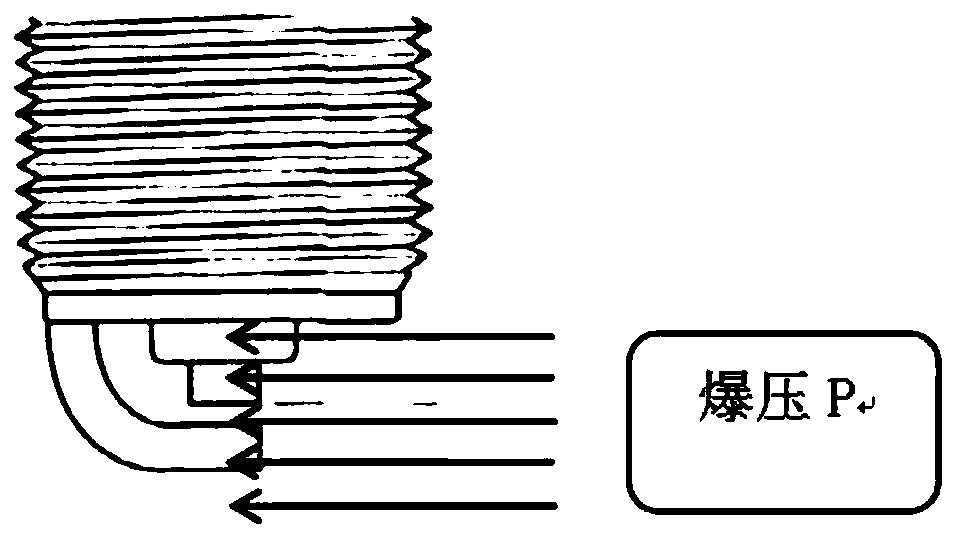

[0028] According to the anti-explosion strength value of the parts and the distribution probability curve of the over-explosion explosion pressure of the bench, the failure probability of the parts due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com