Tensile sample for clad sheet steel substrate

A technology for composite steel plates and tensile samples, which is applied in the preparation, sampling, and analysis of materials for testing, can solve problems such as poor results, and achieve the goal of not affecting detection accuracy, facilitating processing size control, and ensuring processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

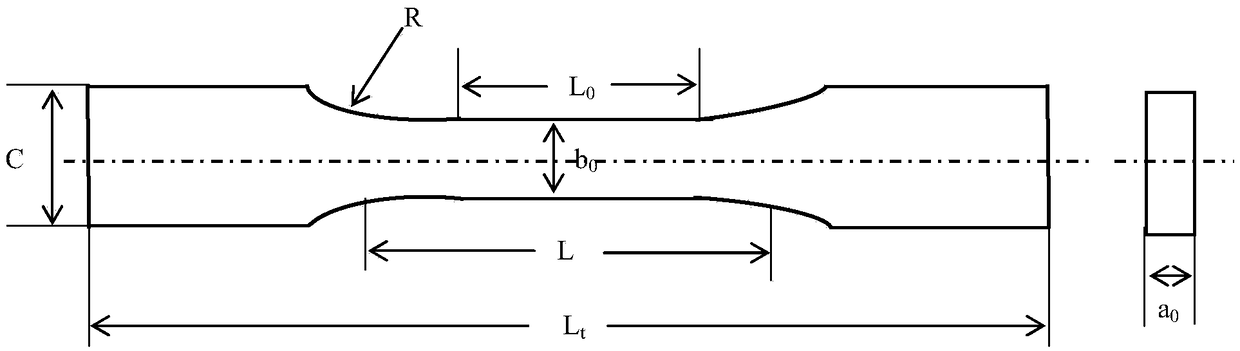

[0032] Such as figure 1 The preparation method of the composite steel plate substrate tensile specimen shown is as follows:

[0033] (1) Take the pipeline steel and stainless steel clad steel plate with a length of 400mm, a width of 100mm, and a thickness of 15.4mm, and remove the oxide scale and dirt on the surface of the clad steel plate for later use;

[0034] (2) the clad steel plate end milling in the step (1) is grown into 400mm, and width is 43mm, and thickness is the lath-shaped standard tensile specimen of 15.4mm, as figure 2 shown;

[0035] (3) the lath-shaped standard tensile sample gained in step (2) is processed into the tensile sample with shoulder with the mode of open shoulder milling; In the tensile sample with shoulder, arc radius is 25mm, The length of the parallel section of the sample is 80mm, the width is 38mm, and the thickness is 15.4mm, such as image 3 shown.

[0036] (4) With wire cutting, the composite layer of the shouldered tensile sample obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com