Photovoltaic power station automatic inspection system based on unmanned aerial vehicle

A technology of photovoltaic power station and inspection system, applied in photovoltaic system monitoring, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of large number of equipment, waste of enterprise cost, and wide area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

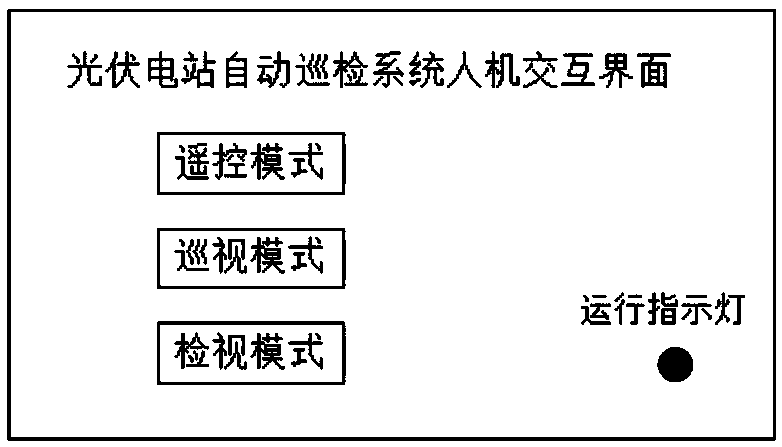

[0025] In order to further elaborate the technical solution of the present invention, achieve the expected purpose and effect. The drone-based automatic inspection system for photovoltaic power plants proposed by the present invention, its control method, implementation, and structural features will be further elaborated and described below in conjunction with the accompanying drawings and embodiments.

[0026] This embodiment discloses a technical solution and a specific implementation method of an automatic inspection system for a photovoltaic power station based on an unmanned aerial vehicle. The system includes:

[0027] UAV as the subject of flight;

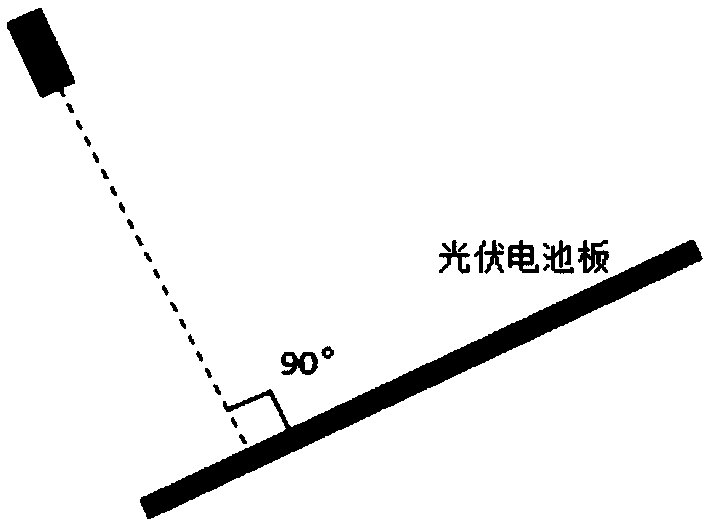

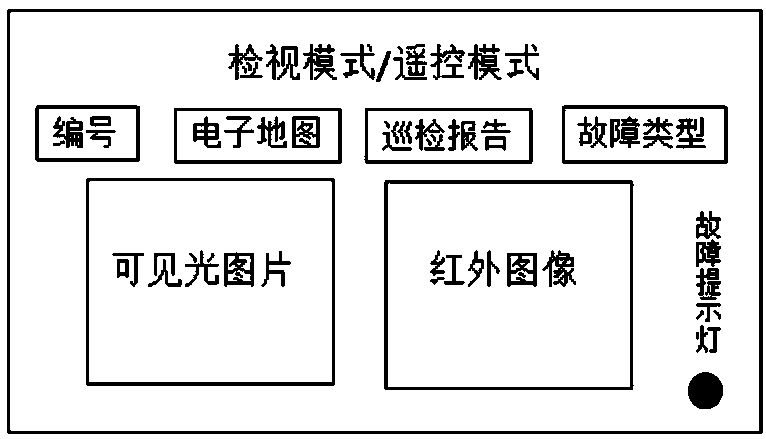

[0028] The airborne module consists of a camera and an infrared thermal imager;

[0029] The path planning module designs and plans the inspection path and method of the UAV, and controls the flight height, speed and path of the UAV;

[0030] The communication module is used for the transmission of image data and control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com