Angle-adjustable ultrasonic probe device

An ultrasonic and angle adjustment technology, used in measuring devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of wasting manpower, labor-intensive, affecting the detection effect, etc., to achieve easy portability and use, Accurate effect of probe angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

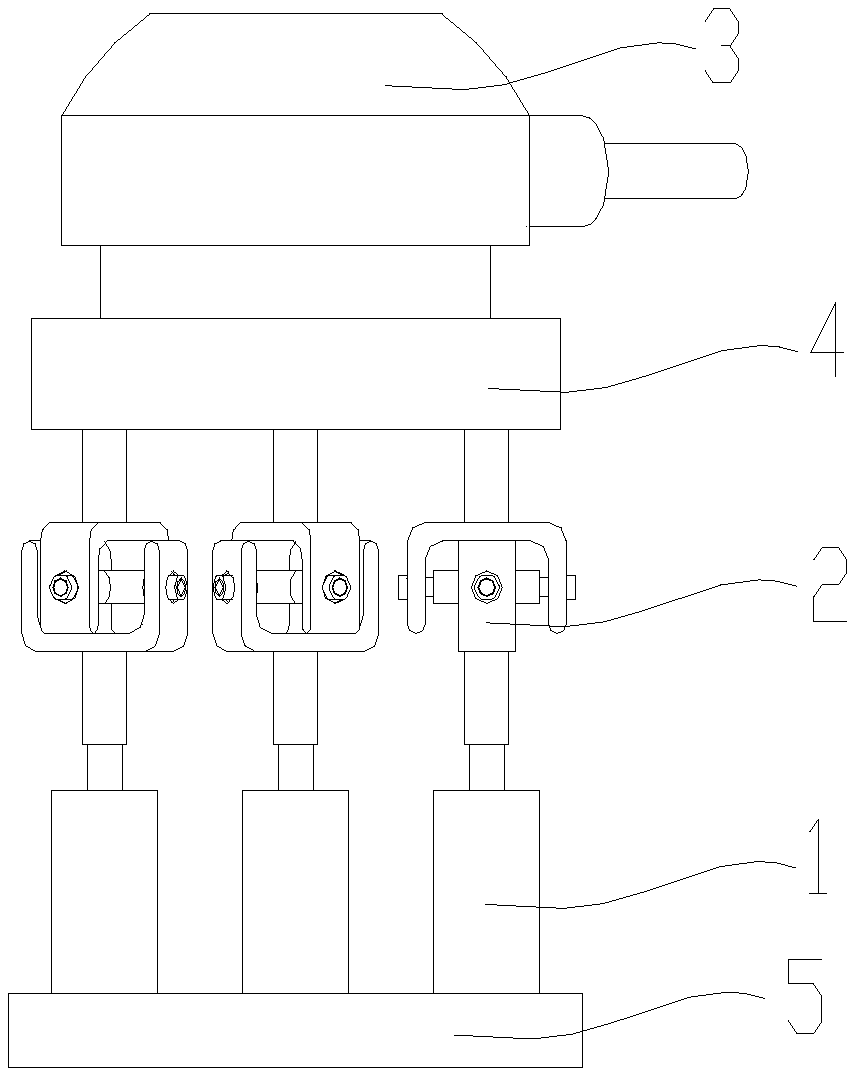

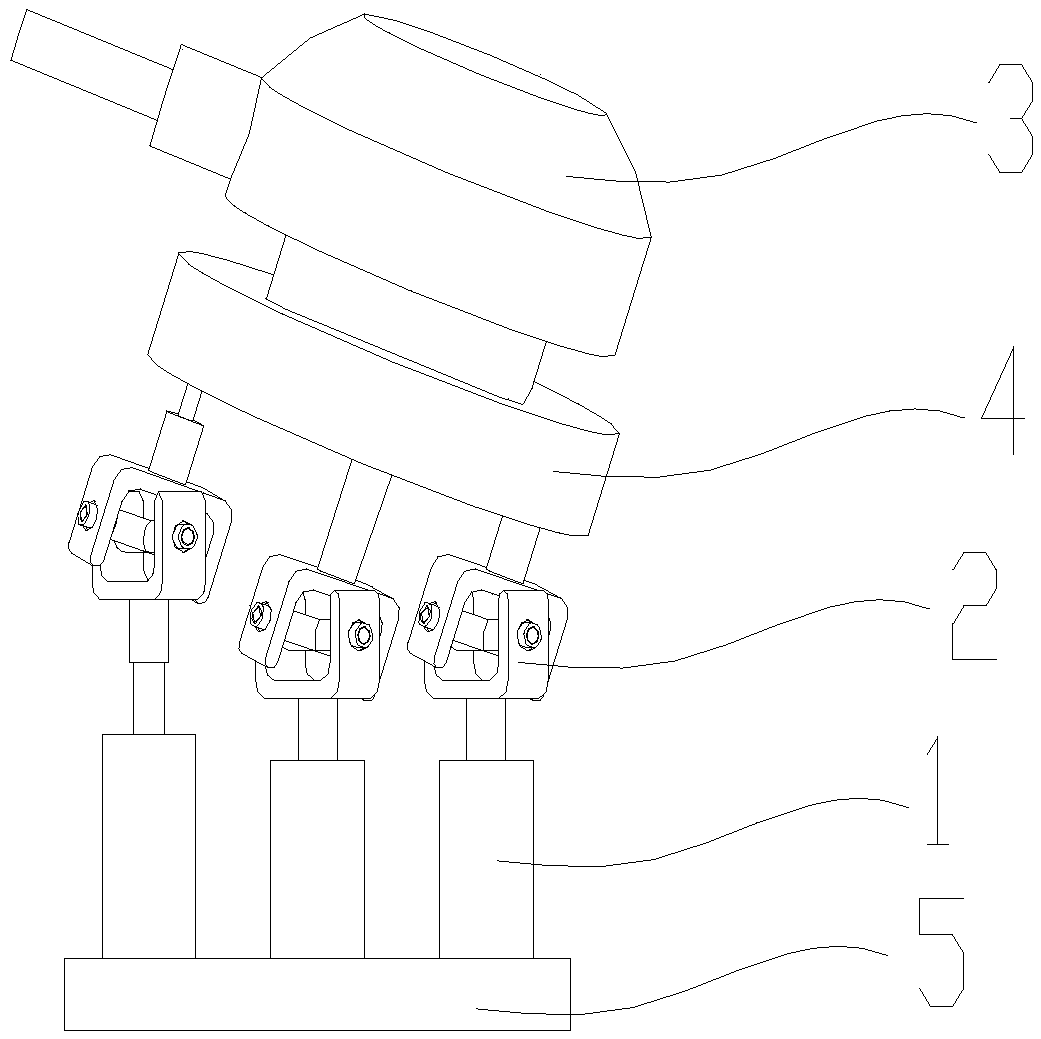

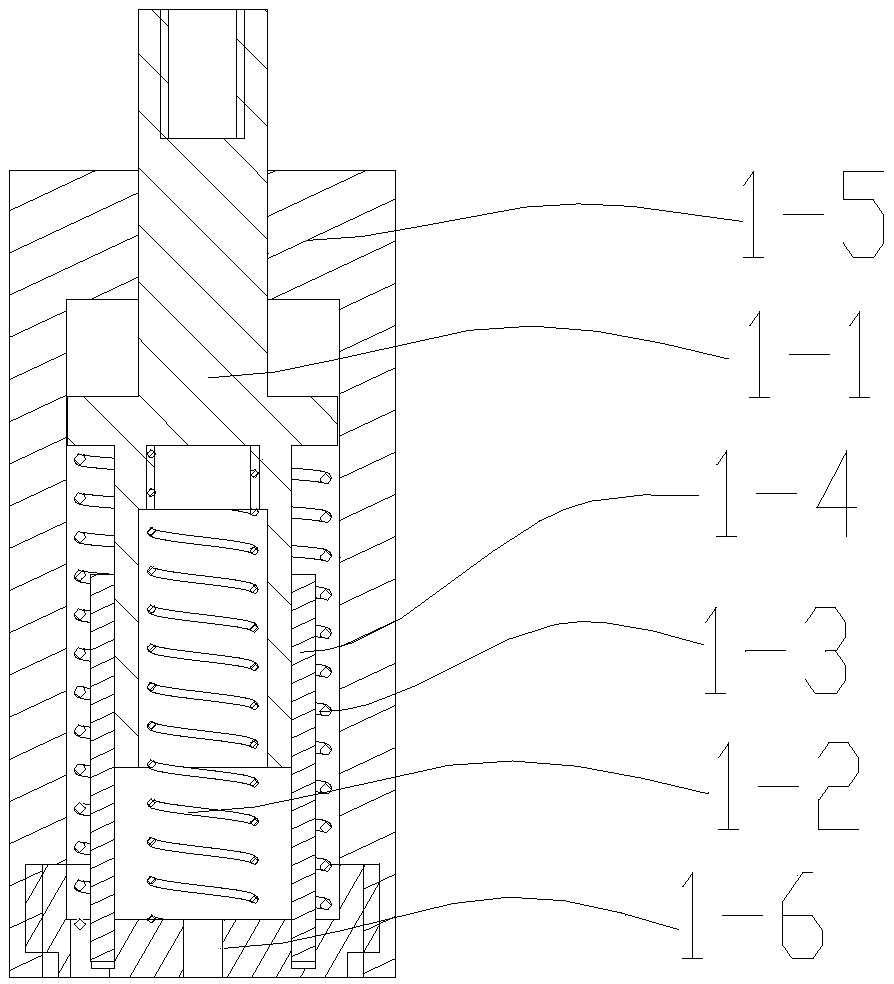

[0031] Such as figure 1 , 2 Shown: the present invention comprises probe 3, platform 4, probe angle adjustment mechanism and base 5, and described probe 3 is installed on platform 4, and described probe angle adjustment mechanism includes at least one angle that is installed between platform 4 and base 5 Adjustment units (set according to actual conditions, such as 1, 2, 3, 4, etc., the present invention is preferably 3 or 4 or 5), the angle adjustment unit includes rotating parts 2 and fixed on the base 5, the telescopic drive assembly 1, the rotating part 2 is composed of a cross shaft universal joint head, one end of the universal joint head is fixed with the platform 4, and the other end of the universal joint head is connected with the telescopic drive The telescopic end of the assembly 1 is fixedly connected, and the telescopic drive assembly 1 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com