Single resistance motor current sampling method, motor drive circuit and readable storage medium

A technology of motor current sampling and motor drive circuit, applied in the field of motor drive circuit and computer readable storage medium, single resistor motor current sampling, can solve motor noise, large harmonic loss of motor drive circuit, pulse current asymmetry, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

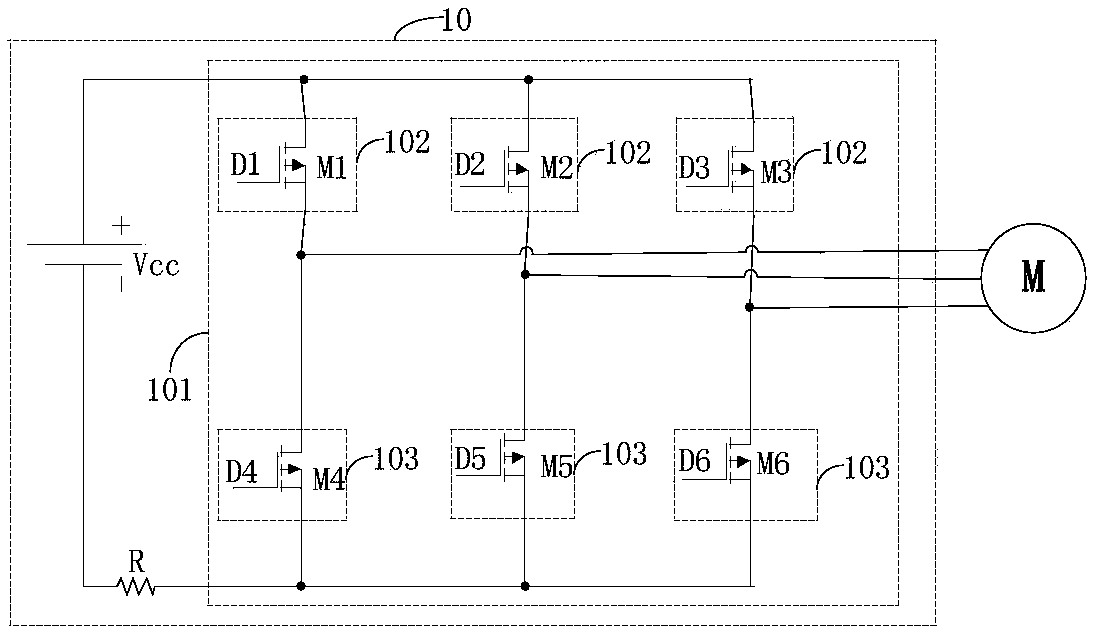

[0028] It should be noted that in the motor drive circuit, sampling the phase current of the motor drive circuit through a single resistor is an extremely effective and simple method in this field. Since the motor drive circuit has different circuit structures, the single resistor sampling method can be Applicable to different types of motor drive circuits; figure 1 For example, figure 1 A schematic diagram of the circuit structure of the motor drive circuit 10 provided by the embodiment of the present invention is shown. The motor drive circuit 10 includes: a power supply Vcc, a drive circuit 201 and a sampling resistor R, wherein the power supply Vcc outputs a power supply, and the drive circuit 201 is based on PWM (Pulse Width Modulation , pulse width modulation) pulse control operation, wherein, PWM pulse is used as the driving signal of the driving circuit 201; specifically, as figure 1 As shown, the drive circuit 201 includes multi-phase bridge arms, and each phase brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com