Failure point positioning method based on high temperature light emission microscopic analysis technology

A positioning method and microscopic analysis technology, applied in the field of failure analysis, can solve the problem of inability to locate the leakage position of the chip, and achieve the effect of improving product quality and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the following technical solutions and technical features can be combined with each other.

[0027] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

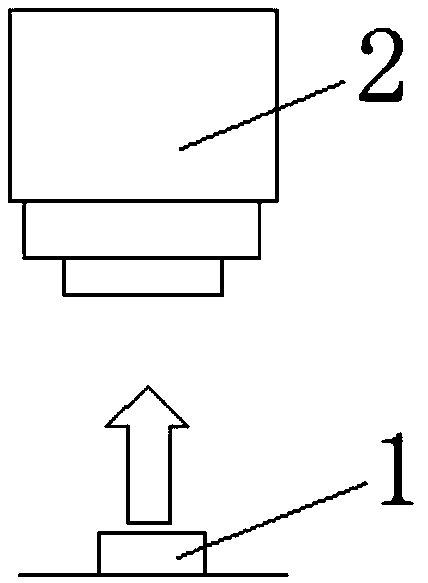

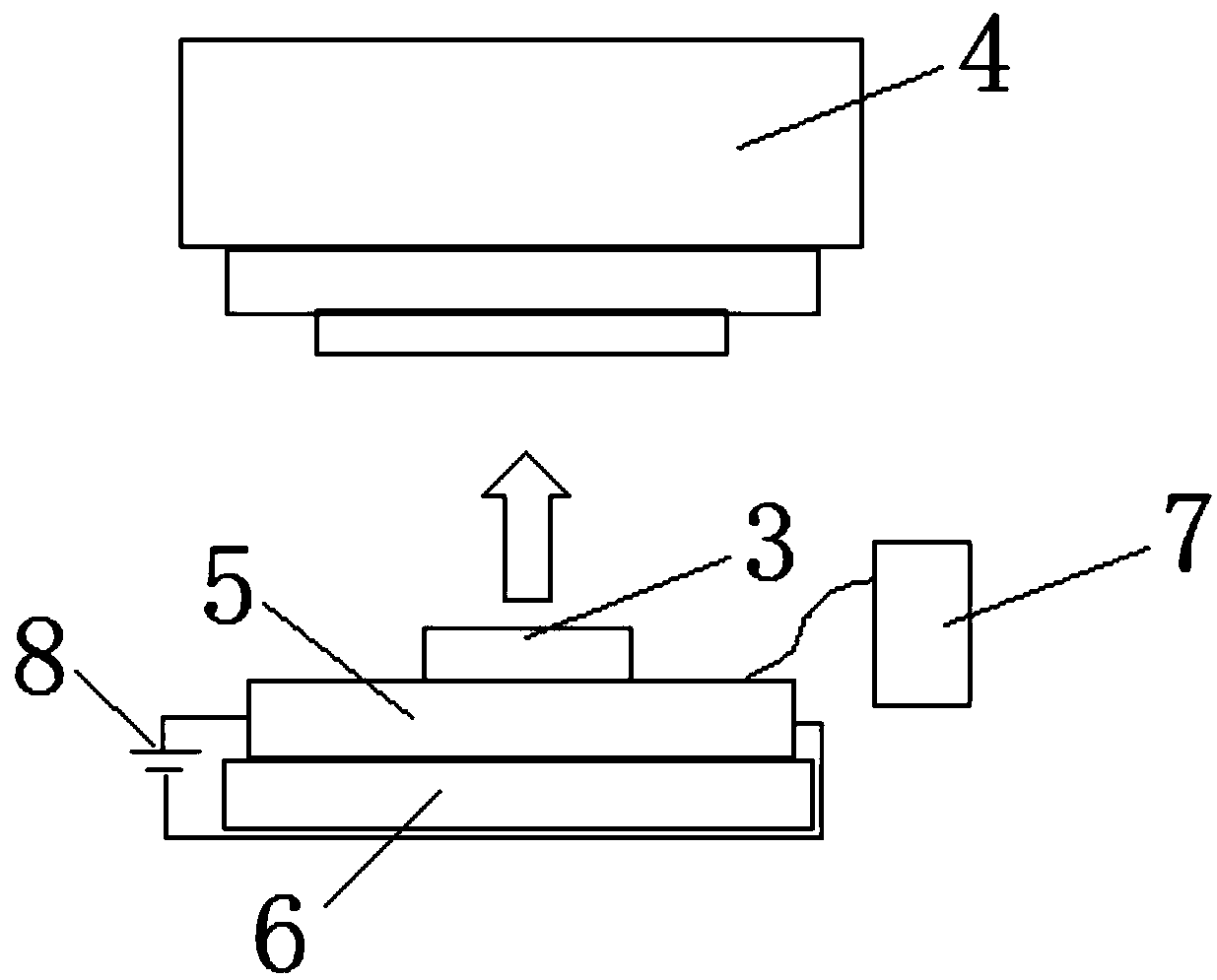

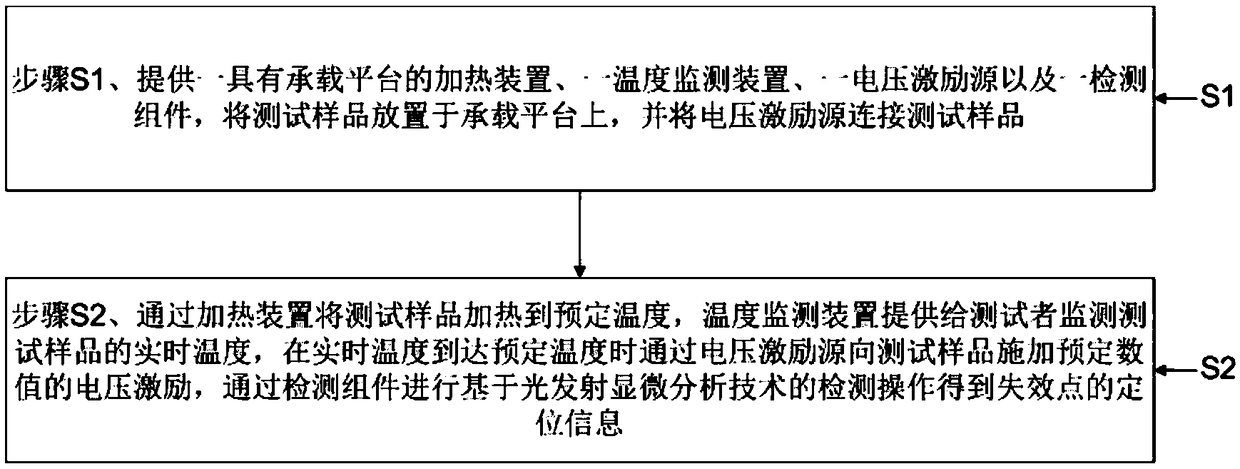

[0028] As shown in 2-3, a method for locating failure points based on high-temperature light emission microanalysis technology is characterized in that it is used to locate the failure point of the test sample 3 in a high temperature environment to obtain the location information of the failure point ; The above implementation methods include:

[0029] Step S1. Provide a heating device with a bearing platform 6, a temperature monitoring device, a voltage excitation source 8 and a detection component, place the test sample 3 on the bearing platform 6, and connect the voltage excitation source 8 to the test Sample 3;

[0030] Step S2. The test sample 3 is heated to a predetermined temperature by the heating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com