Compact small reactor-loop main equipment structure connected by short pipes

A compact and small-scale reactor technology, applied in the field of nuclear power, can solve the problems of difficult to meet the safety requirements of pipelines, occupy a large space, and cannot apply to the limited installation space of the cabin, and achieve the advantages of less space, reduced pipeline flow resistance, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

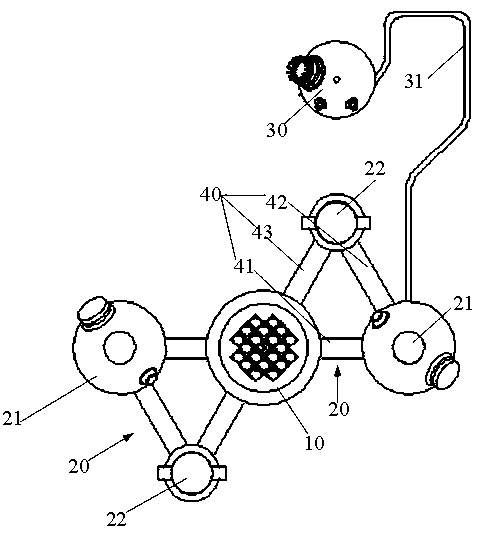

[0023] like figure 1 As shown, the primary equipment structure of a compact small-sized reactor connected by short pipes in a preferred embodiment of the present invention includes a reactor body 10, two loops 20 connected to the reactor body 10, and a voltage stabilizer 30, wherein the voltage regulator The device 30 is connected to any one of the two loops 20 for adjusting and maintaining the pressure in the loop formed by the reactor 10 and the two loops 20 .

[0024] The two loops 20 are arranged symmetrically and, in this embodiment, centrally symmetrically with respect to the reactor body 10 . Each loop 20 includes a steam generator 21 and a main pump 22, wherein the steam generator 21 is connected to the reactor body 10 through a short pipe 41 to form a first flow channel inside, and the main pump 22 is connected to the steam generator 21 through a short pipe 42 The second flow path is formed inside, and the main pump and the reactor body 10 are connected through a sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com