Self-power-generating energy-saving pruning shear

A technology of pruning shears and self-generating power, which is applied in current collectors, electromechanical devices, electric vehicles, etc. It can solve problems such as laborious, inconvenient use, and inability to cut thick branches, and achieve the effect of improving battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

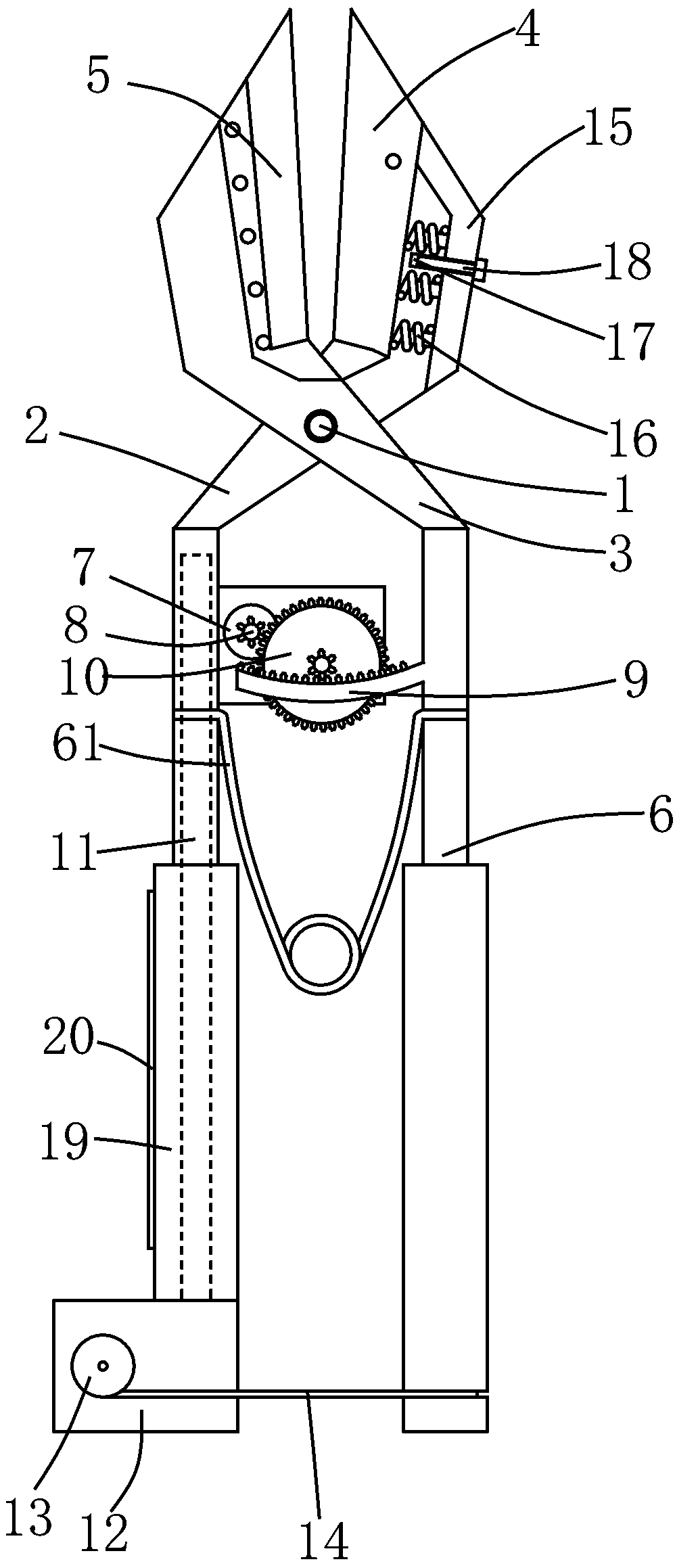

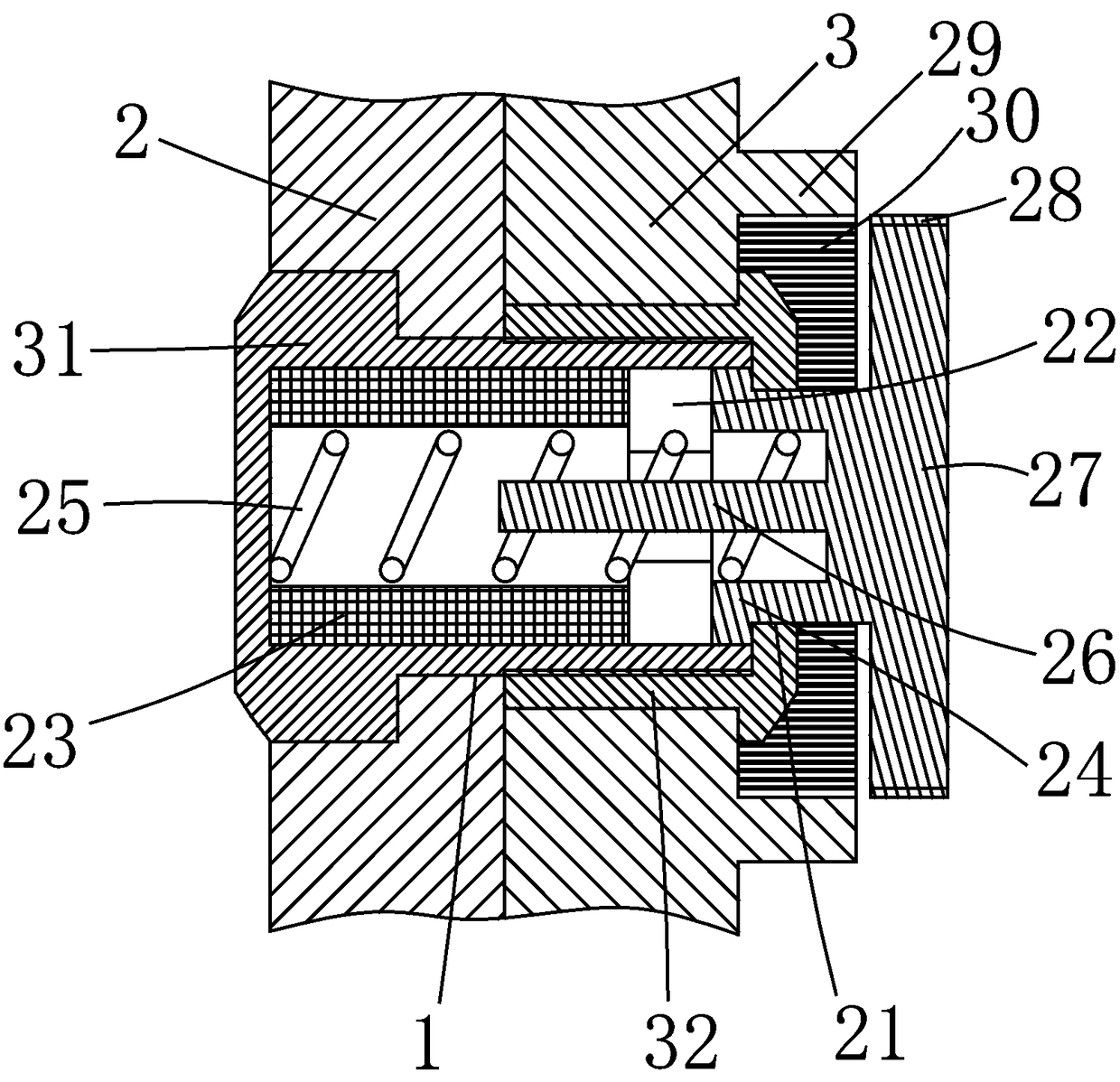

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 2 , a kind of self-generating energy-saving pruning shears, including a first rotating arm 2 and a second rotating arm 3 hinged to each other through a hinge 1, the first rotating arm 2 and the second rotating arm 3 are located at the hinged position One side is respectively provided with a first cutting edge 4 and a second cutting edge 5 which cooperate with each other, and the other side of the first rotating arm 2 and the second rotating arm 3 at the hinged position is a handle 6, the A first spring 61 that bounces off the first rotating arm 2 and the second rotating arm 3 is provided between the handles 6, and the first rotating arm 2 is provided with a power generation assembly 7, and the power generation assembly 7 The rotating shaft is connected with a first gear 8 through a one-way bearing, and the second rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com