Mining ball mill and electric control system thereof

A ball mill and mining technology, applied in the field of mining machinery, can solve the problems of grinding balls that cannot be ground, high temperature, and restrictions, and achieve the effects of improving grinding efficiency and effect, reducing manufacturing costs, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

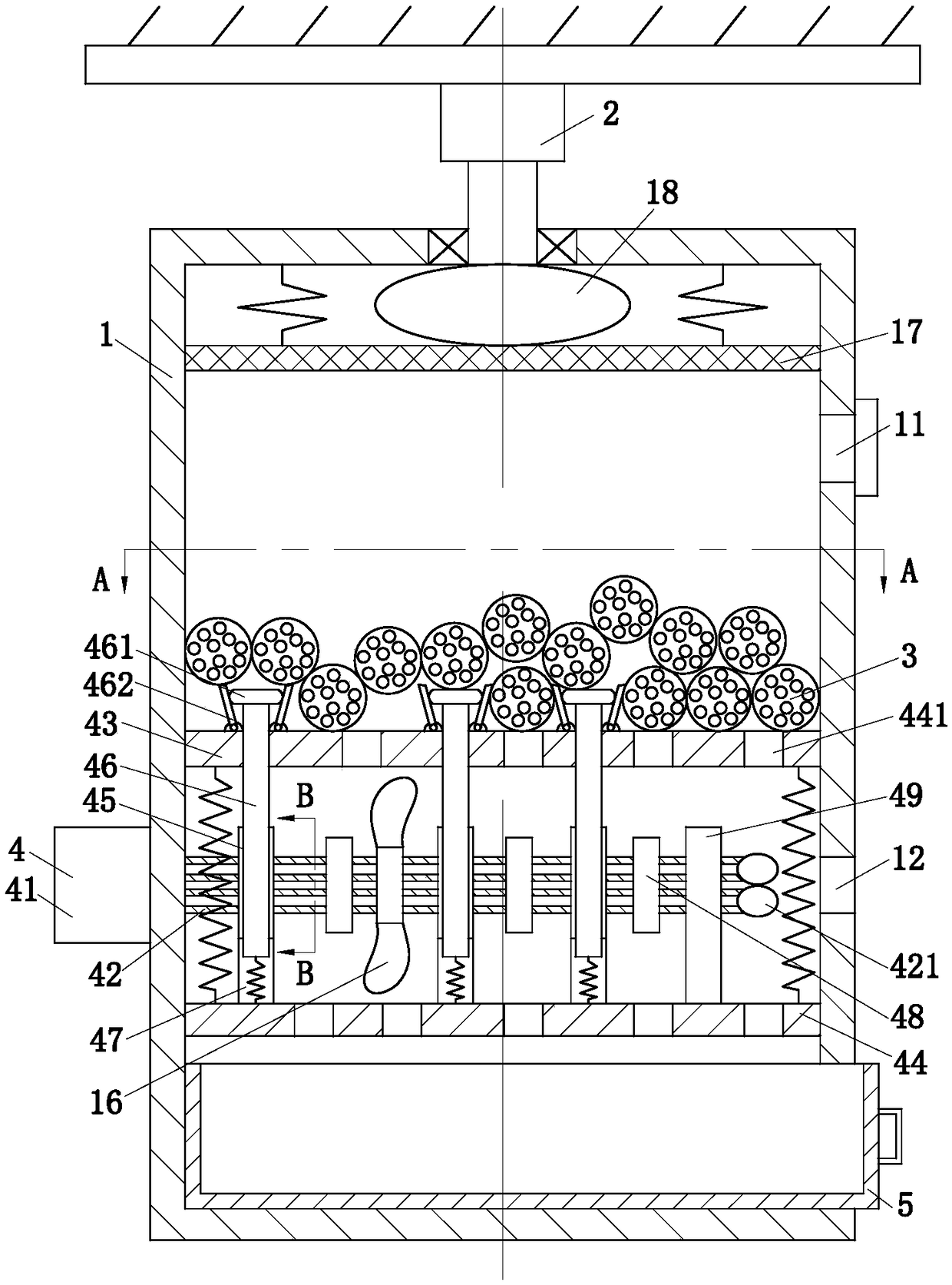

[0044] As an embodiment of the present invention, the top of the cylinder 1 is provided with an elastic plate 17; the elastic plate 17 is fixedly connected to the inner wall of the cylinder 1 by a spring, and the elastic plate 17 is used to buffer the grinding ball 3 against the cylinder. body 1 collision. In the process of bouncing the grinding ball 3, the grinding ball 3 hits the top of the cylinder 1, and the top of the cylinder 1 is subjected to a strong impact force, which is easy to cause damage to the cylinder 1, thereby affecting the grinding efficiency of the gold ore particles; An elastic plate 17 is provided, through which the impact of the grinding ball 3 on the top of the cylinder body 1 is avoided, and a force is given to the grinding ball 3, so that the grinding ball 3 moves in the opposite direction, and the grinding ball 3 continues to grind the gold during the opposite direction movement. The ore particles are subjected to impact grinding, thereby improving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com