Cylindrical grinding machining device for insulation barrel of carbon felt and method thereof

A technology of cylindrical grinding and processing device, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding workpiece support, etc. problem, to achieve the effect of improving grinding efficiency and effect, improving grinding effect and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

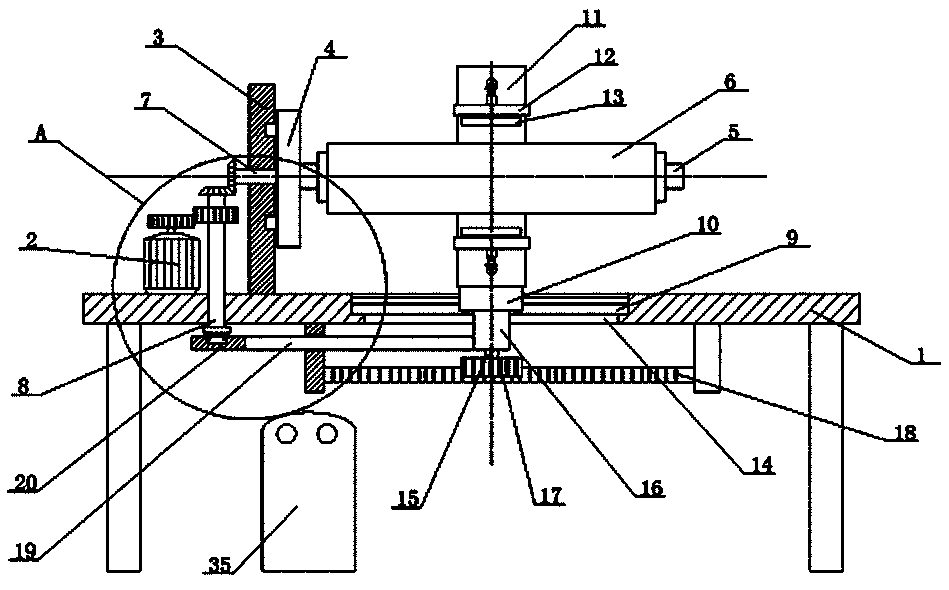

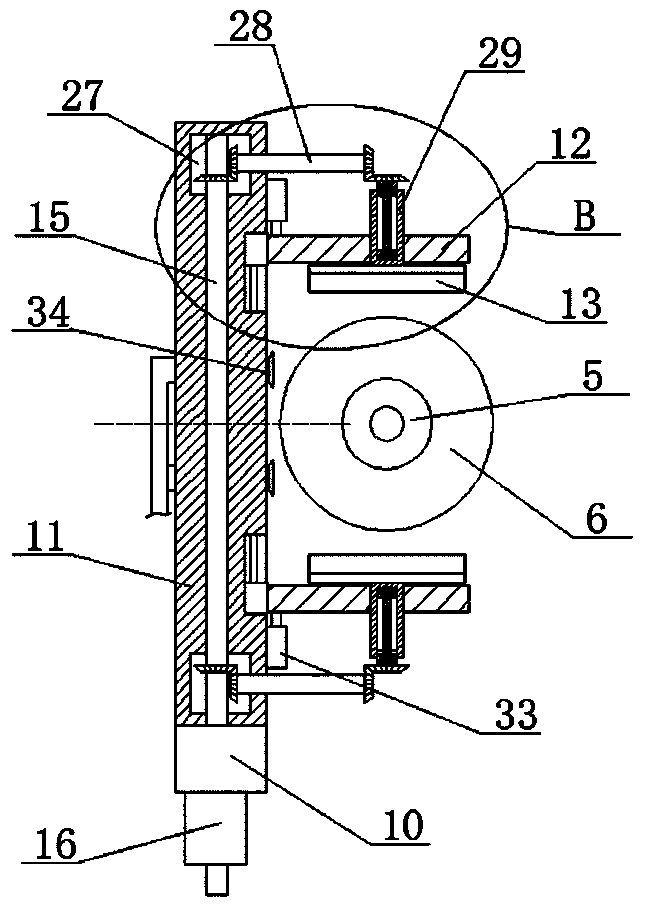

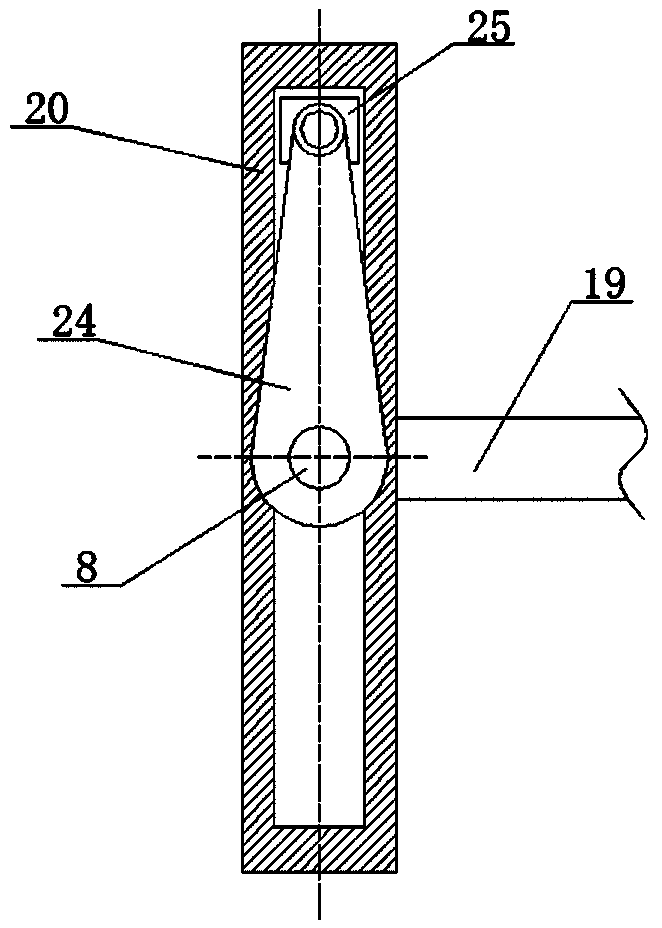

[0044] refer to Figure 1-5 , a kind of cylindrical grinding processing device for carbon felt insulation cylinder, comprising workbench 1, the top of workbench 1 is fixedly connected with servo motor 2 by screws, and the top of workbench 1 is fixedly installed with vertical plate 3 by welding, vertical plate 3 A connecting shaft 5 is installed on the top to rotate, and an insulating cylinder 6 is movable outside the connecting shaft 5. The servo motor 2 cooperates with the connecting shaft 5. A moving plate 11 is slidably installed on the top of the workbench 1, and a sliding plate is installed on one side of the moving plate 11. Two transverse plates 12, the sides of the two transverse plates 12 close to each other are equipped with a grinding wheel 13 for rotation, and the moving plate 11 is fixedly connected with two push rod motors 33 by screws, and the output shafts of the two push rod motors 33 They are respectively fixedly connected with the two transverse plates 12 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com