A Necking Die with Reduced Necking Instability Tendency

A shrinking and trending technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of scrapped parts, easy instability of the lower half of the blank, waste of materials, etc., to achieve strong shrinkage ability and save molds. Capital investment, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

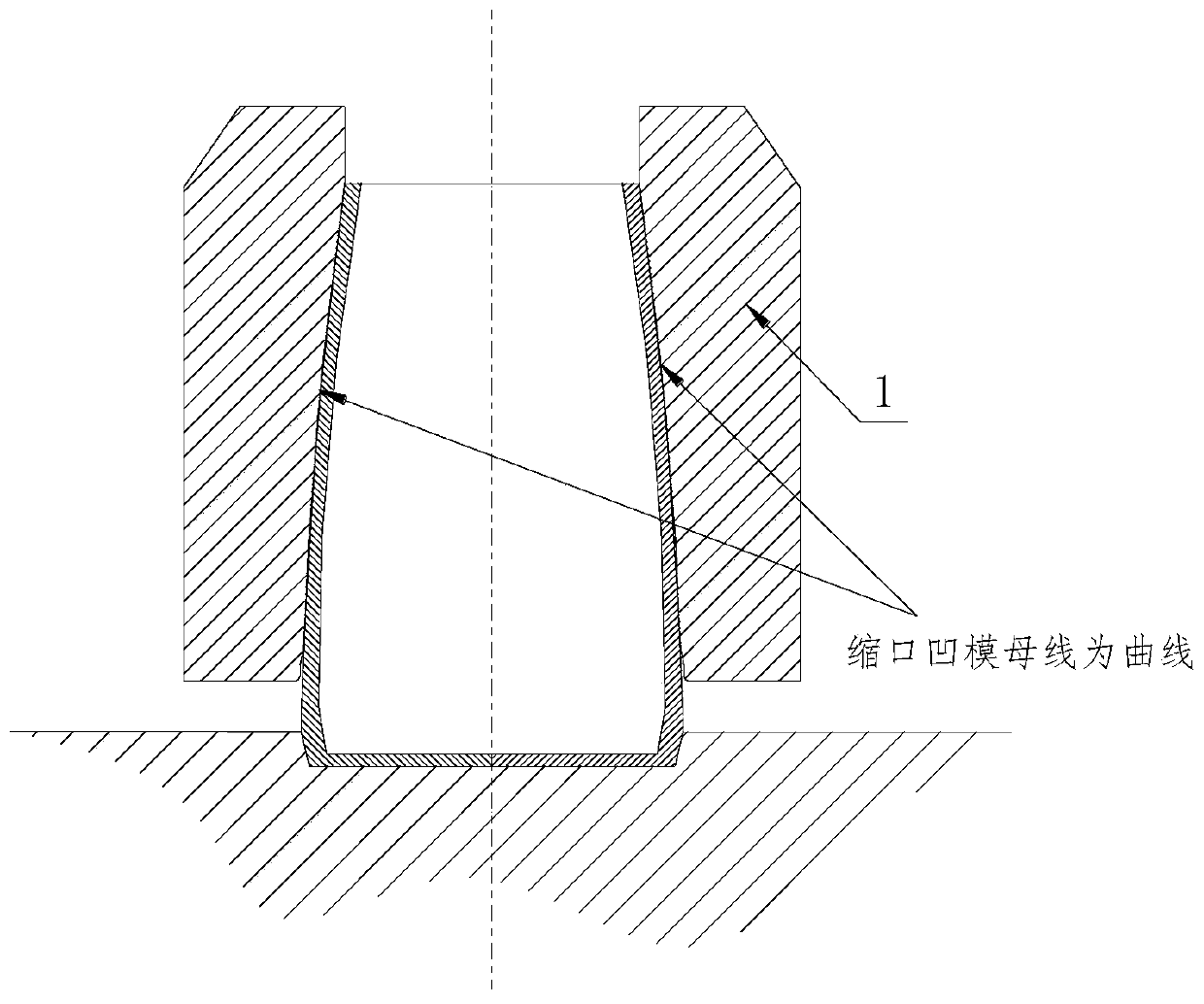

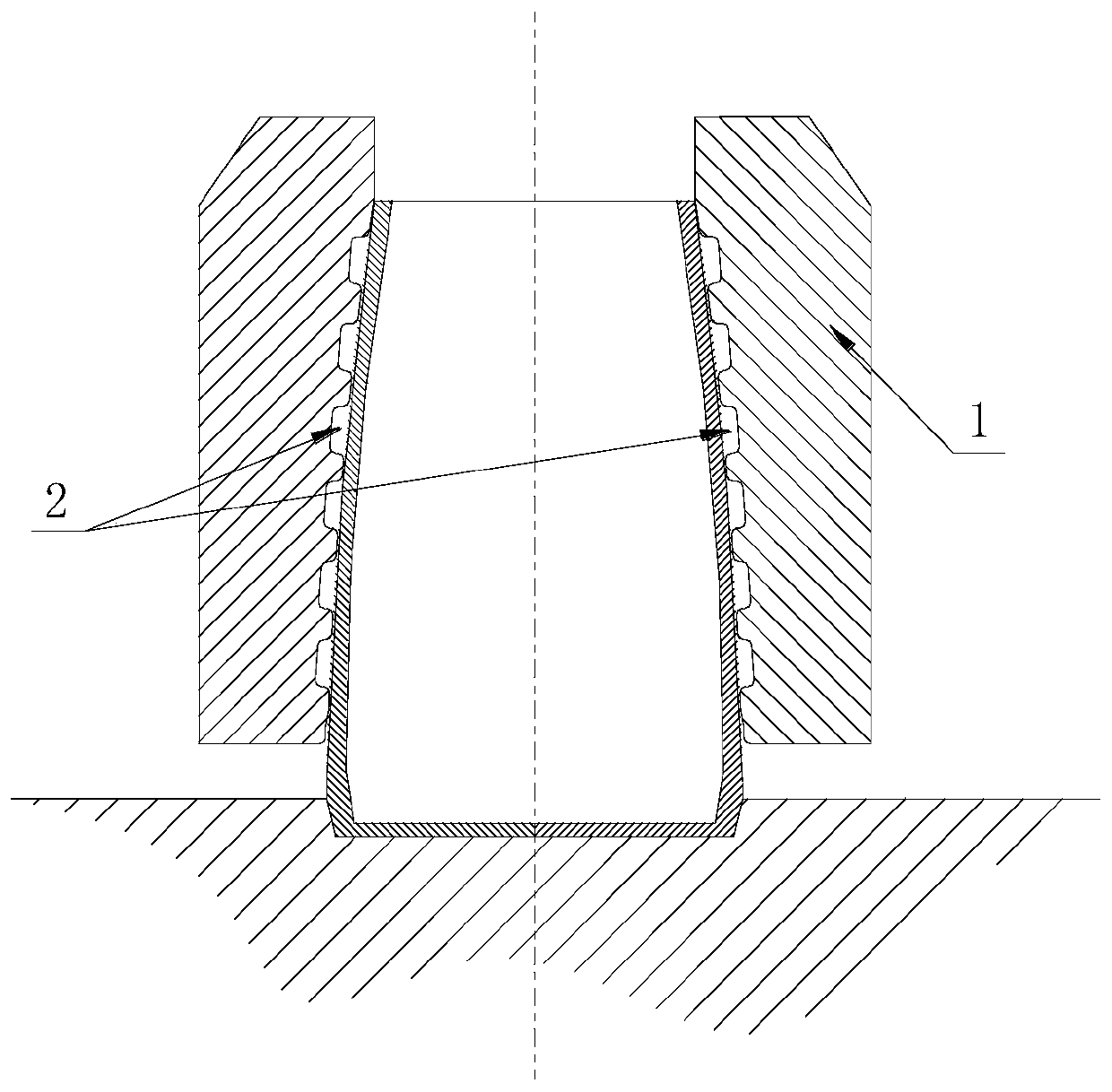

[0025] Such as image 3 and Figure 5 As shown, in this embodiment, a necking die that reduces the tendency of necking instability is based on the fact that the generatrix of the inner wall of the necking die 1 is a curve, and multiple transverse annular grooves are set on the inner wall of the necking die Groove 2, the ratio of the height H of the inclined wall of the inner wall of the shrinking die to the height L of the transverse annular groove is the straight-to-space ratio H / L, the straight-to-space ratio is 1:1.2, and the depth t of the transverse annular groove 2 is 2mm . The number of transverse annular grooves 2 can be 5-10 in the height dimension of the shrinking die.

Embodiment 2

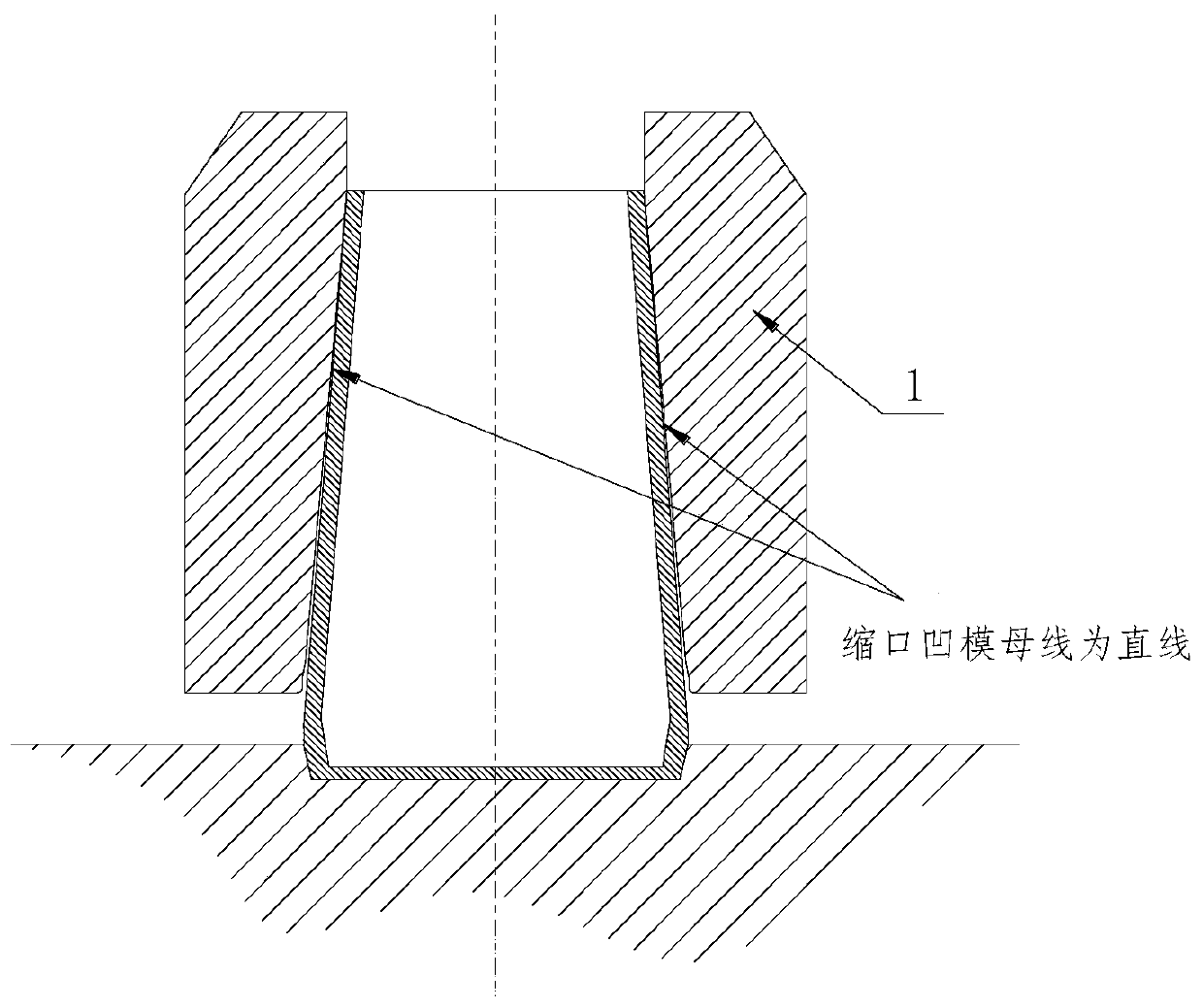

[0027] Such as Figure 4 and Figure 5 As shown, in this embodiment, a necking die that reduces the tendency of necking instability, on the basis that the generatrix of the inner wall of the necking die 1 is a straight line, multiple transverse annular grooves are arranged on the inner wall of the necking die Groove 2, the ratio of the height H of the inclined wall of the inner wall of the shrinking die to the height L of the transverse annular groove is the straight-to-space ratio H / L, the straight-to-space ratio is 1:1.5, and the depth t of the transverse annular groove 2 is 3mm . The number of transverse annular grooves 2 can be 5-10 in the height dimension of the shrinking die.

[0028] The selection of the generatrix form of the inner wall of the shrinking die is determined according to the outer contour of the product and the machining allowance.

[0029] The straight-to-empty ratio can be arbitrarily selected in the range of 1:1-1:1.6.

[0030] The depth t of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com